Recode seams

![]()

This function sorts the input Seam Block Model file by East then North then Z (descending) and then inspects each 'column' of blocks (those with the same East and North centres). If an overburden code is defined, any records with that value in the Material field are ignored. The function assumes that all remaining records are either Interburden (Partings) or Coal (Plies). You can either use a Stratigraphy file to define the seam (coal) codes, or you can define Interburden using a Regular Expression match for the Material field.

Once the coal codes are able to be determined, the function scans down the 'column' until it finds a coal block and checks the Interburden thickness between that and the next coal block. If it is less than the Maximum interburden thickness the coal blocks will be treated as though they were a single unit, and coded accordingly. It then repeats this test until it finds a parting greater than the Maximum interburden thickness. All the records that are part of this coal “seam” are coded as per the seam coding “rule”.

There are 2 additional constraints:

- If a Formation field is defined, then seams cannot be combined if they are in different formations (you can use this field in a more generic way. By selecting a field that defines Classification, for example, you can ensure that there is amalgamation of Measured and Indicated coal).

- The unit being combined MUST be contiguous. If the column contains “gaps” these are honoured. Although it is unlikely that the Seam Block Model file will have such gaps, they might be introduced if a filter is applied.

Finally, each coal unit is checked against the minimum seam thickness value.

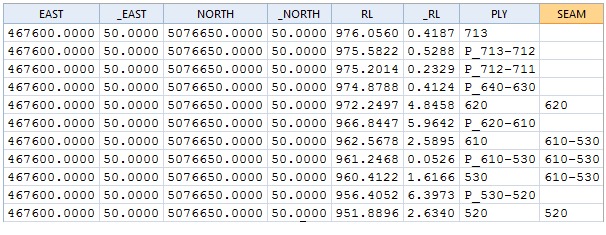

In the example above:

| Material field = PLY |

| Minimum seam thickness = 0.5 |

| Maximum interburden thickness = 0.5 |

| Seam field = SEAM |

| Seam coding = ABOVE-BELOW |

|