Output

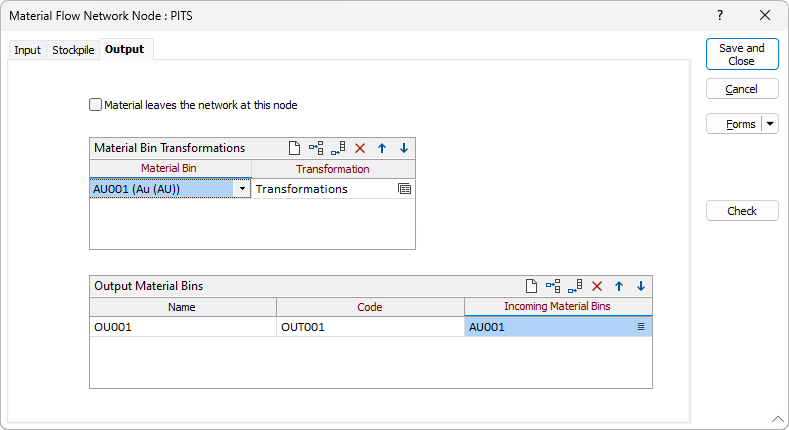

Use the Output tab of the Material Flow Network Node form to

Output material bins are configured on the on the Material Network Node > Output tab to name and define the material withdrawn from the stockpile/s. Output bin contents cannot be defined for stockpiles, as stockpile output material is implicitly defined to be all the material arriving at the stockpile.

When the Stockpile Element Grades grid has been configured, click the Output tab to continue.

Select the Material leaves the network at this node option to mark the node as a point where material leaves the stockpile. This will disable the Material Bin Transformations grid where the node is not marked as Material enters... or Material can be stockpiled...

If neither of these options have been selected on the Input tab and the Stockpile tab, the Material Bin Transformations grid must be configured.

Material Bin Transformations

Select the Material Bin for the transformation from the drop down list of the configured material bins.

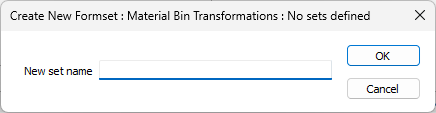

Right click in the Transformations field and select New or click the form icon to create a new transformation form set:

Enter a New set name for the form set in the field and click OK to define it. The Material Bin Transformations form opens.

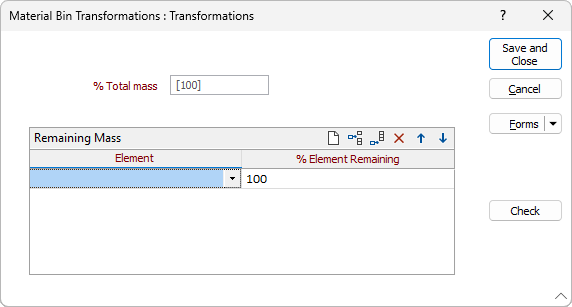

Enter the % Total mass value in the field to represent the percentage of total mass for the material bin transformation.

Remaining Mass

In the Remaining Mass grid, you can select the elements for the transformation and the % of the element remaining once the transformation is complete.

Select an Element for the material bin transformation from the drop down list of the elements configured.

In the % Element Remaining field, enter the percentage value for the selected Element that will remain after the transformation.

You can use the tools for the grid to Manage the rows in the list and add any additional elements to the Remaining Mass as required.

When the required elements and remaining values have been configured in the grid, click Save and Close to return to the Output tab.

Output Material Bins

In the Output Material Bins grid, you can configure the material bins used to receive the material at the completion of the flow.

Enter a Name for the output material bin in the field provided.

Enter a unique identifying Code for the out material bin. This value is compulsory.

Use the List button to select the related input bins for the output bin from the Incoming Material Bins form.

You can use the tools for the grid to Manage the rows in the list and add any additional bins to the Output Material Bins as required.

When the Material Flow Network Mode form has been completed, click Save and Close to retain the new details and return to the Material Flow Optimisation form.

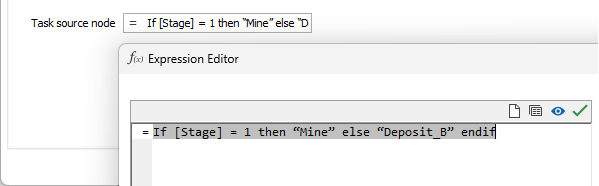

In the Sources and Destinations tab, the Task Source Node field allows you to specify the node for the task sources from which the tasks of the schedule will be generated.

You can enter the name of the source or destination node or click the equals icon to enter an expression to define the node to be selected: