Planner

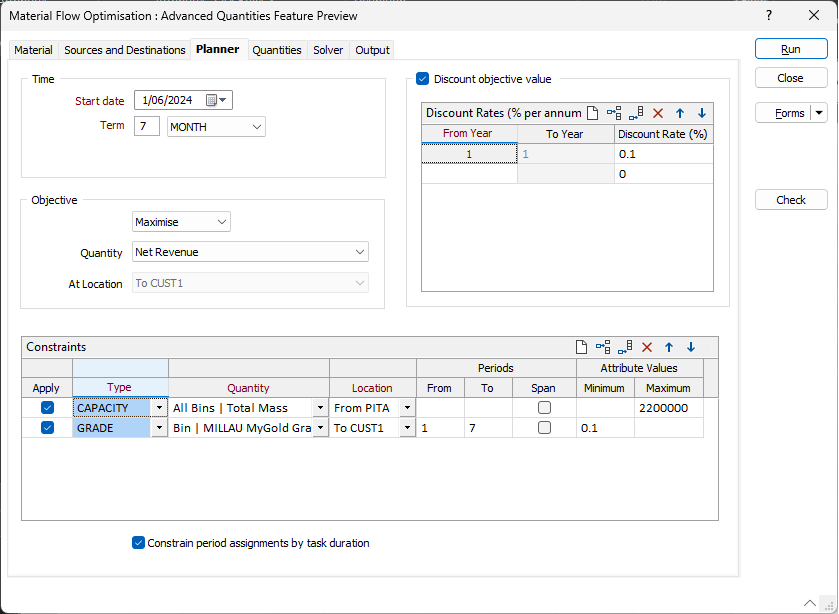

On the Planner tab of the Material Flow Optimisation form, you can set the Time, Objective and Constraints configuration for the Material Flow Optimisation.

Optimise Material Flow: Planner tab

Time

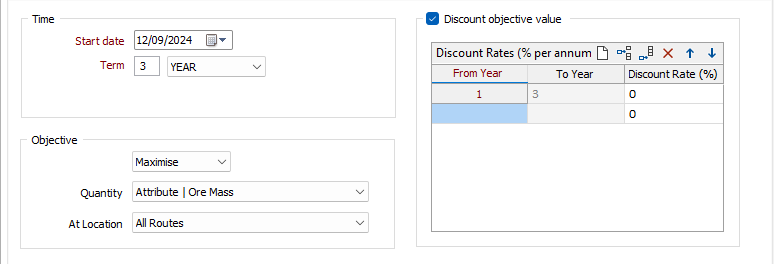

Set the Start Date for the material flow optimisation plan using the Calendar.

Enter the Term length for the plan and select a term measure from the drop down - Year, Month, Week or Day.

The selected Start Date and the Term entered will determine the time scale of the optimisation plan.

Objective

Using the drop-down at the left in the Objective group, select whether the plan is to Maximise or Minimise the material quantity for optimisation.

Quantity

Use the Quantity drop-down to select the quantity to which the objective applies. Named (custom) quantities defined on the Quantities tab of the Material Flow Optimisation form are available for selection. You can also select quantity attributes or material bin quantity attributes.

Right-click (F4) on the Quantity field to create or edit a Material Flow Quantity.

At Location

Use the drop-down to select the route/s for the optimisation process.

Discount objective value

When the Discount objective value check box is selected, a Discount Rate (%) is used to define the objective for the specified quantity. The “Discount Rate Per Period” grid list allows the discount rate to change over time.

Constraints

-

CAPACITY

-

Mining capacity – maximum amount of rock that can be mined in one period.

-

Processing capacity - maximum amount of ore that can be handled by the processing plant in one period.

Capacity constraints (per period). Examples are:

Right-click on a CAPACITY constraint in the Constraints grid, to create or edit a Material Flow Quantity in the Material Flow Quantity form.

-

GRADE

The Grade constraint ensures that (weighted average) grade values meet a specified minimum and/or maximum value per period.

-

DISTINCT

The Distinct constraint is used to limit the number of unique values of the specified attribute between the specified Minimum and/or Maximum.

-

SEQUENCE

The Sequence constraint ensures that tasks are sequenced in ascending order of the values of the chosen attribute. The Minimum and Maximum columns are not used.

Periods

The From and To periods for which constraints apply. Where applicable, specified Minimum and Maximum values apply to each period (the Span check box is unselected by default). If the Span check box is selected, specified Minimum and Maximum values apply across all periods.

The Period attribute will be populated by the optimisation process. Each period will contain only complete blocks. In other words, there is no consideration for a block to be partially mined at the end of one period with mining completed in the following period.

Constrain period assignments by task duration

It is possible for the solver to assign many tasks all belonging to a dependency chain to the same period, if all other constraints allow it. If the end-to-end duration of such a chain is longer than the period duration this results in tasks being "pushed out" into the following period.

When this option is selected, tasks which are later in a dependency chain that would be pushed into another period are constrained to be assigned to a later period.