Drillhole From Target

![]()

A drillhole design in which the direction of the drillhole trace is opposite to the drilling direction, running from the target to the collar, is a From Target design.

A from-target design is typically used when the target location is known and the collar location is to be determined. For surface drilling this method optionally includes automatic clipping to a surface DTM, automatic reversal of the drillhole trace, and automatic extension beyond the target.

From target-design supports straight or curved up-holes or down-holes.

The application uses the segment length to control the length of each segment that represents a curved hole. When the segments are converted to Collar and Survey files, the segment length also determines the interval between successive downhole surveys.

The safest way to plan a curved hole is to start by interactively adding segments until the hole is the right length. You can then design other holes using total length once you get a feel for how they relate to your project area.

To interactively add segments to a trace, starting at a defined target location:

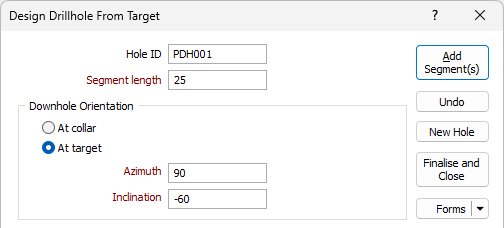

Digitise a point as the target location. The Design Drillhole from Target form is displayed:

Hole ID

(Optional) Enter a unique identifier for the hole in the Hole ID field.

Segment length

Enter a segment length (in grid units).

Downhole Orientation

In the Orientation section of the dialog, specify length, orientation, and deviation of the hole.

Enter an Azimuth and an Inclination for the initial segment of the trace. The trace will deviate from this start orientation.

The orientation of the trace can be defined at collar or at target.

Regardless of the design direction (from collar or from target), the application always expects the orientations and deviations to be specified in the drilling direction, not the design direction.

For example, if you are designing a from-target hole, which will be drilled at -60° towards the east (090°), then you should enter an inclination of -60 and an azimuth of 90, even though you are designing the hole upwards from the target. The application will automatically reverse the directions and deviations for you.

The drilling direction and design direction are independent variables.

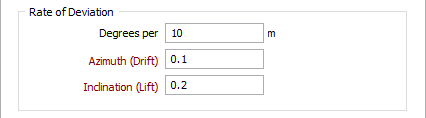

Rate of Deviation

The segments that you add to the trace will deviate in their orientation, over a specified segment length and by a specified Azimuth deviation and Inclination deviation, measured in degrees per segment. Deviations are defined in terms of the drilling direction.

Degrees per units distance

Enter a value in the field to define the distance to which the rate of deviation applies. The unit of distance, determined by the project settings, is displayed at the right of the field. When left blank, this value will use the Segment length.

Use the rate of deviation options with care. Drillhole deviation is the result of a complex interaction between the drilling parameters (bit type, feed pressure, rotation speed etc.), the cutting or hammering action of the bit, the rocks through which the hole passes, and the angle between the drill bit and the fabric of the country rock. Changing any one of these parameters may result in significantly different rates of deviation compared to other holes.

In a new project area, you should plan for straight holes until you have enough drilling to understand how the prior holes deviated. Even with this knowledge you should always consider any planned deviation to be an approximation of the completed drillhole.

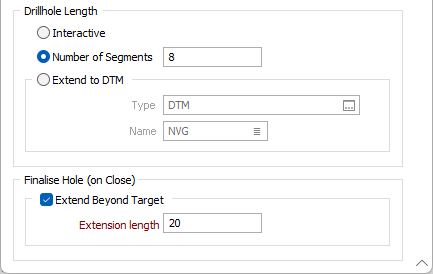

Drillhole Length

Note: If you have chosen an At Collar downhole orientation (above), the collar location and the drillhole length are determined by the intersection point on the DTM. You cannot define the length interactively or by specifying the number of segments.

Interactive

Select this option to adjust the length of the hole interactively rather than specify a total length or calculate the length based on the number of segments.

Number of segments

Multiple segments can be added using the same orientation or the same deviation specified in the form. Enter the number of segments to create.

Extend to DTM

Alternatively, specify the Type and Name of a DTM to snap to. The point at which the DTM is pierced by the trace string will determine the length of the hole.

Finalise Hole (On Close)

If selected, the following option will determine what happens when you click the Finalise and Close button and close the form:

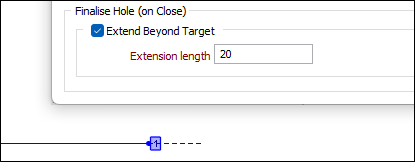

- Extend Beyond Target will lengthen the hole by a specified Extension length. A preview line for the extension is shown in the display:

Add Segment(s)

Click the Add Segment(s) button to add one or more segments of the specified length and orientation.

Undo

Click Undo to undo one or more of the segments you have added.

Close

Click Close to close the form without finalising the hole.

Forms

Click the Forms button to select and open a saved form set, or if a form set has been loaded, save the current form set.