Material Bins

This function is also available on the Mining tab, in the Task Preparation group.

![]()

A typical use case would be a detailed reserve estimation scenario. In this scenario, the function is used to interrogate mineable wireframe(s) against a block model to determine the quantities and qualities of different material bins, for example: high grade, medium grade and low grade ore reserves.

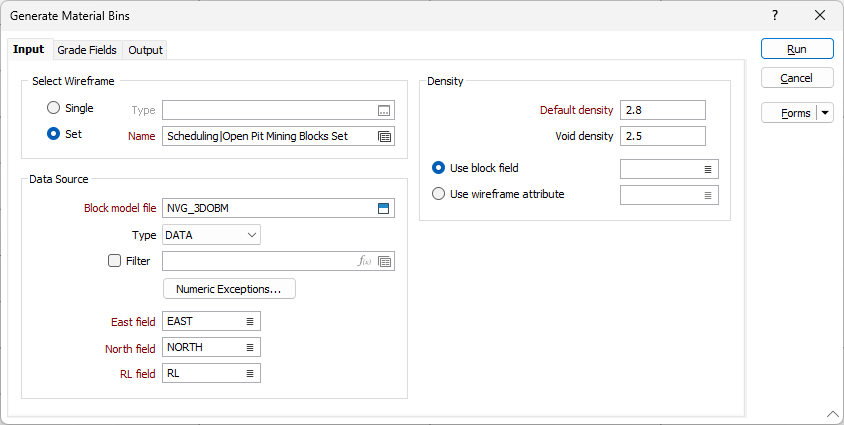

Input

The primary inputs to the Generate Material Bins function, are a Micromine block model file, a wireframe or wireframe set, and a material bins set.

Select Wireframe

To process a single wireframe, select the Single option, select the Type of the wireframe, and then the Name of a wireframe of that type.

To process multiple wireframes, expressions, wildcards and partial names may be used in the Name field to select multiple wireframes as an adhoc wireframe set. A right-click Preview option will perform a check of an expression before using that expression to generate an updated list of wireframes. Alternatively, you can click the Expression icon ![]() and use the Expression Editor to create, modify and validate the expression. When a name or wildcard is entered in the Name field, and the Expression button is selected, the name/wildcard will automatically be converted to a valid expression when opened in the editor.

and use the Expression Editor to create, modify and validate the expression. When a name or wildcard is entered in the Name field, and the Expression button is selected, the name/wildcard will automatically be converted to a valid expression when opened in the editor.

To process the wireframes in a predefined wireframe set, select the Set option.

It is recommended that you Validate wireframes prior to using them in any process.

Data Source

A block model is the source of the relevant element fields, grades, and material bins, specified in the material set.

The grade value of each block is weighted according to the volume of the block that is inside the wireframe. If the block lies completely inside the wireframe, then a simple calculation, using the block dimensions, takes place.

If the block intersects the wireframe, a Boolean calculation determines the exact volume of the portion inside the wireframe.

Block Model File

File

Double-click (or click on the Select icon) to select the name of the Input file. The default file type for Block Model data is DAT. If necessary, you can apply a filter to restrict the process to a subset of the data in the file.

East, North and RL fields

Specify the names of the fields in which Easting, Northing, and RL coordinates are stored in the Input file.

Numeric Exceptions

(Optionally) Use the Numeric Exceptions group to control the way that non-numeric values are handled. Non-numeric values include characters, blanks, and values preceded by a less than sign (<).

Density

Note: For Imperial projects, Density

Specify the source of the density values used by the function. Density values are treated in a similar way to grades. That is, you can direct the function to obtain them from several sources.

Default density

You must enter a default density value. This will be used when a Density value is missing from a record in the input file, from a wireframe attribute, or from a material set (if specified).

Void density

Optionally, specify a default density for the void.

Void represents regions where no block model cells intersect the wireframe(s) being interrogated. For example, void regions may be present when an Ore block model does not fully cover the extents of a pit that is being evaluated.

For this void region, the block model grades are scaled to encompass the whole volume, using the default grades as the void grades. When you run the function, the values for the block, and the void, are reported for each wireframe.

Note: Specifying a void density and configuring the void attribute settings is recommended when using an ore block model.

Use block field

Select this option to use the density values from a field in the input file. Click on the List icon to select the field.

Use wireframe attribute

Select this option to use the density values of a wireframe attribute. Click on the List icon to select the attribute.

Create attributes for void material

Enable this check box if you wish to write Volume and Density attributes for void material to the wireframes.

Enter (or click on the List icon to select) the names of the attributes. if you enter the name of an attribute that does not already exist, you will be prompted to create that attribute.

Forms

Click the Forms button to select and open a saved form set, or if a form set has been loaded, save the current form set.

Run

Finally, click Run to run the function. (To view the Report file, right-click with the cursor in the Report file response).