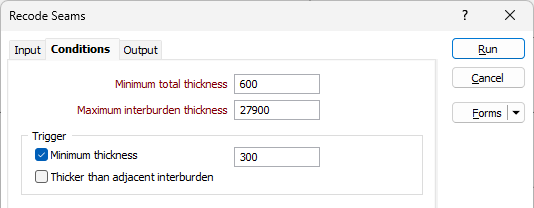

Conditions

Set the conditions that will be applied when coding the seams as coal or waste.

Minimum total thickness

When the process of combining coal plies and checking the thickness of interburden is complete, a final check is made to ensure that each coal unit is greater than the Minimum total (seam) thickness.

Maximum interburden thickness

The function will check the interburden thickness between successive coal blocks. If it is less than the Maximum interburden thickness the coal blocks will be treated as though they were a single unit and coded accordingly. The function then repeats the process until it finds a parting greater than the Maximum interburden thickness.

Trigger

The initial definition of the working sections that will be used in a mine, is typically made in the field by the geologist supervising the drilling program. These definitions are often made on the basis of rules of thumb such as:

| Coal less than 30 cm thick cannot be mined separately; partings more than 30 cm thick will be mined separately; and if a coal seam is less than 50 cm thick and the parting above or below is thicker than the coal, the coal will be wasted. |

Minimum thickness

If this option is selected, an attempt to recode will not commence unless the coal thickness is greater than the specified Minimum thickness value. The same applies to the last coal in a recoding group.

Thicker than adjacent interburden

If this option is selected, an attempt to recode will not commence unless the coal thickness is greater than the interburden immediately below it. Equally the last coal, in a recoding group, must be thicker than the interburden immediately above it.

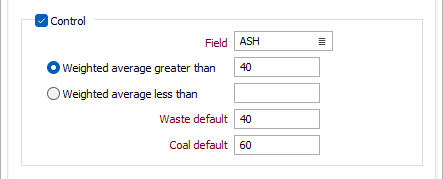

Control

If the Control option is selected and a Control Field is defined, the Weighted Average value of this field, for all records in the recoding group, must be greater than (or less than) a user defined value.

| A typical example is Ash < 40%. This also allows “manual” control over the recoding, by allowing the user to populate this field with (say) 0 or 1. Another possibility is to assign 0 or 1 to the control field depending on whether a record is coal or waste. You can now force the recode to have (say) 60% coal. |

Waste and Coal Default values are used when the cell is blank.

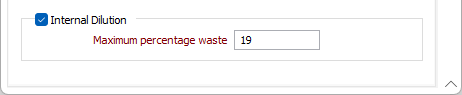

Internal Dilution

If this option is selected, the process will look at ALL records in the recoded group. The Total coal thickness is compared to the Total waste thickness and the percentage waste is calculated. If this is greater than the defined Maximum percentage waste the recoding fails.