Report

![]()

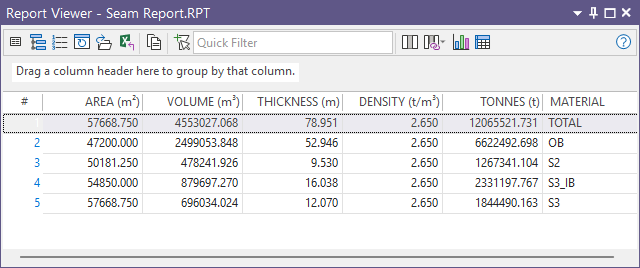

The report will include the Area, Volume, Thickness (Volume/Area), and Tonnage for each seam. Waste can be excluded from the report either by setting an appropriate filter or by selecting “Exclude Waste”. Define waste is a Regular Expression match for the Material field (see Strip Ratio function).

Waste can be excluded from the report either by setting an appropriate filter or by selecting an Exclude Waste option (see below).

Input/Output

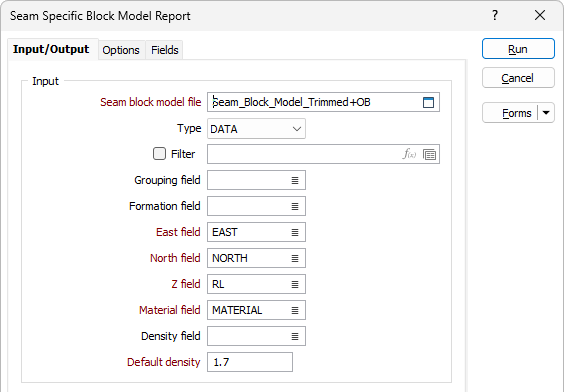

Specify the following parameters on the Input/Output tab of the Seam Block Model Report form:

Seam Block Model file

Specify a Seam Block Model file as the input file. Seam block models use variable-height blocks, which are not limited to a set sub-blocking interval. Seam splits, plies and partings are easily defined.

Grouping field

(Optional) Double-click (F3) to select the name of the field that contains the values that the report will be grouped by. If a Formation field is selected, for example, then the report is grouped by Formation.

Formation field

(Optional) Double-click (F3) to select the name of the field that contains the values that identify each formation. A Formation is a group of seams, modelled independently.

East, North and Z fields

Specify the East, North and Z coordinate fields in the input file. The function uses these fields to define the block centres.

Material field

Double-click (F3) to select the name of the Material field. The Material field is compulsory and typically contains Seam (and Interburden) names.

Density and Default density

Specify a Density value or double-click (F3) to select a Density field in the Seam Block Model file. Density is used to calculate tonnage, but it also comes into play when you choose Tonnes for Block weighting of Estimate fields (see below).

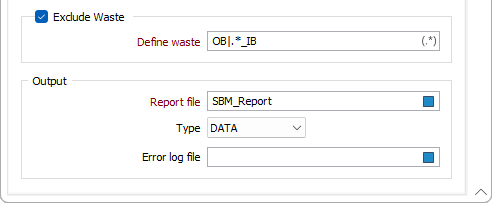

Exclude Waste

Waste can be excluded from the report by selecting the Exclude Waste check box (or by setting an appropriate filter).

Define waste

Define

Although regular expressions can be both complex and powerful, a couple of simple suggestions should provide an easy way to define waste codes. The first thing to understand is that the Regular Expression must match the complete code, not just a part of it. There are 3 characters and quantifiers that will allow matching of most waste codes. They are:

| Character | Description | Pattern | Possible Matches |

|---|---|---|---|

| . | Matches any single character | .B | IB or OB |

| * | Matches previous element zero or more times | .*IB | AT01_IB or FC22_IB |

| | | Matches any element separated by pipe (|) | OB|.*IB | OB or AT01_IB or FC22_IB |

Some examples:

| Waste Codes | Patterns that match |

|---|---|

| OB, AE_IB, FJ_IB, KL_IB | OB|AE_IB|FJ_IB|KL_IB |

| OB|.*_IB | |

| .*B | |

| OB, PT_AE, PT_FJ, PT_KL | OB|PT.* |

Regular Expressions are used elsewhere in the application.

Output

Report file

Enter or double-click (F3) to select the name of the output report file.

The report will include the Area, Volume, Thickness (Volume/Area), and Tonnage for each seam. Waste can be excluded from the report either by setting an appropriate filter or by selecting “Exclude Waste”. Define waste is a Regular Expression match for the Material field (see Strip Ratio function).

Error log file

(Optional) Enter or double-click (F3) to select the name of the file to which errors will be logged.

Forms

Click the Forms button to select and open a saved form set, or if a form set has been loaded, save the current form set.

Run

Finally, click Run to generate the report. Estimates will be calculated. For very large seam block models, this can take a few moments.