Stockpiles

When ore is mined faster than it can be processed, the unprocessed ore can be sent to one or more stockpiles (subject to constraints on the capacities and the material bins accepted by those stockpiles) pending the availability of suitable processing facilities. If a stockpile is not available to accept the unprocessed ore, the mining rate is reduced to ensure that the amount of unprocessed ore mined remains with the capacities of the processing facilities.

When ore is processed faster than it can be mined, unprocessed ore is transferred from the stockpiles to the processing facilities.

Within the context of the built-in material flow model, stockpiles operate between the mine and the processing facilities. Stockpiling (warehousing) of processed product pending sale is not supported.

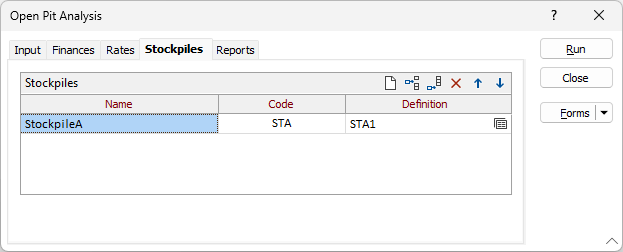

Use the Optimisation > Analyse Pits > Stockpiles tab to specify the list of stockpiles to which unprocessed ore may be sent, along with the following settings for each one:

Name

Enter the name of the stockpile for which the parameters are specified.

Code

Enter the identification code to be assigned to the stockpile for which the parameters are specified.

Definition

Select the form set that specifies the details of the stockpile.

Click left on the icon to select an existing form set.

Click right on the icon and select New to create a new form set. When prompted, enter the name to be assigned to the new form set and press OK.

Click right on the icon and select Edit, or press F4, to edit the specified form set.

The Stockpile form will be displayed.