Input

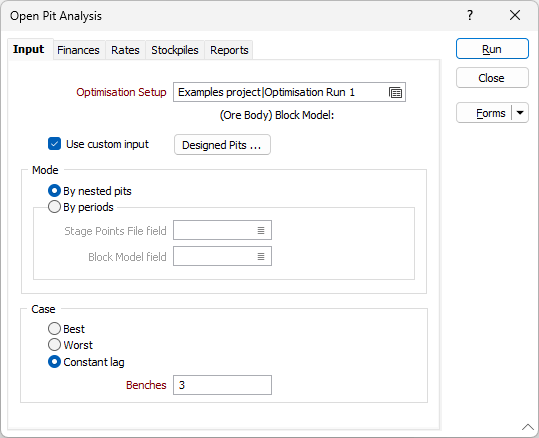

Use the Pit Optimisation > Analyse Pits > Input tab to specify the inputs to the open pit analysis.

Click on the Forms icon (or press F3) to select the name of the Optimisation Setup form set that specifies the block model and contains the parameters of the optimisation to be analysed.

Use custom input

Select this check box to use a Designed Pit (or nested pits) as input to the analysis.

Mode

Choose whether to perform the analysis for each nested pit or for each period.

By nested pits

The analysis of nested pit shells allows the optimum pit shell to be selected and the future discounted financial cash flow to be determined, taking into account the discount rate and other parameters, such as capital costs and recurring expenses.

By periods

If analysing by periods:

- Choose whether a specified field in the Stage Points File should be updated with the period to which those points were assigned in the analysis.

- Choose whether a specified field in the Block Model File should be updated with the period to which those blocks were assigned in the analysis.

Case

Three (3) mining sequence options are available for analysis. Each mining sequence uses different criteria to identify the set of blocks to be included in each increment of the pit. All blocks in each pit increment are assumed to be mined and processed simultaneously. If an increment cannot be mined and processed entirely within a single period, a pro rata portion of that increment is taken and the remainder is included in the next period.

The table below summarises the mining sequences that can be analysed.

| Scenario | Per Bench (Layer) Increment | Comments |

|---|---|---|

|

Best case |

Difference between current and previous pit shells |

• Working from smallest nested pit to largest, mines each pit in its entirety, bench by bench from top down. • Often not feasible because many increments are too narrow. • Useful for determining upper limit on Net Present Value (NPV). |

|

Worst case |

Defined by boundary of largest pit |

• Mines largest pit, bench by bench from top down. • Does not use smaller nested pits. • Generally feasible, but significant early waste stripping may be required in early stages, which brings costs forward and reduces Net Present Value. • Useful for estimating lower limit on Net Present Value. |

|

Constant lag |

Difference between current and previous pit shells |

• Working from smallest nested pit to largest, mines each pit bench by bench from top down (as per Best case). • Commences next nested pit following completion of required number of benches (“lag”) in current nested pit. • Often more realistic. • Setting lag to 0 (zero) enables simultaneous mining of all nested pits, resulting in Worst case. • Setting lag to maximum number of benches from all nested pits prevents mining of next nested pit until current has been completed, resulting in Best case. • Lag defines “moving window”. For example, setting lag to 3 enables mining of bench 2 in next nested pit with mining of bench 5 in current nested pit. |

If there is no significant difference between the Net Present Values obtained for the Best case and Worst case, you can assume that the Net Present Value for the project will be relatively insensitive to the mining sequence adopted.