Scheduling

This

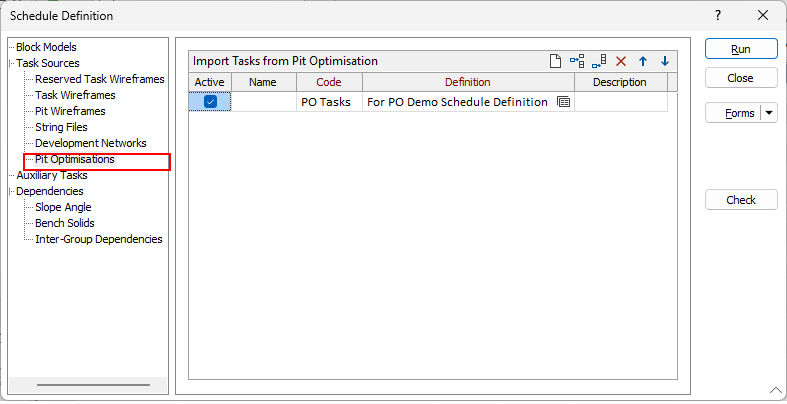

Task Sources from Pit Optimisation

On the Task Sources tab of the Schedule Definition form, you can now generate tasks from a Pit Optimisation form set.

When you select Pit Optimisations as a task source, the Scheduler will create task solids from the intersection of pit shells and benches, and do reserving onto the wireframes from the block model specified in the Pit Optimisation form set. Tasks are annotated with attributes for all relevant information generated by the Pit Optimisation, including material bins and elements, extraction numbers, etc., and imported into the schedule.

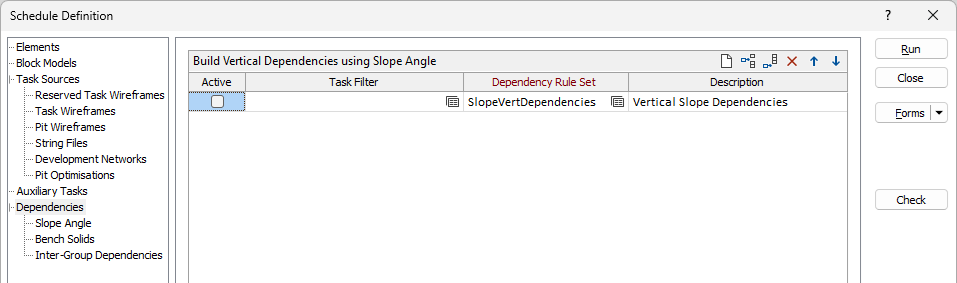

Pit Optimisation Dependencies

On the Dependencies tab of the Schedule Definition form, setup a list of rule sets to be used to establish Slope Angle, Bench Solids or Inter-Group dependencies between the tasks in the schedule.

|

On the Slope Angle tab, you can create and configure slope angle rules which determine the slope and stage attributes, as well as the block sizes for the slope angle dependencies. |

|

| On the Bench Solids tab, you can setup a list of rule sets to be used to create vertical dependencies between the bench solids created from pit optimisation, | |

| On the Inter-Group Dependencies tab, you can create and configure a list of rule sets to be used to establish the dependencies between groups of tasks in the schedule. |

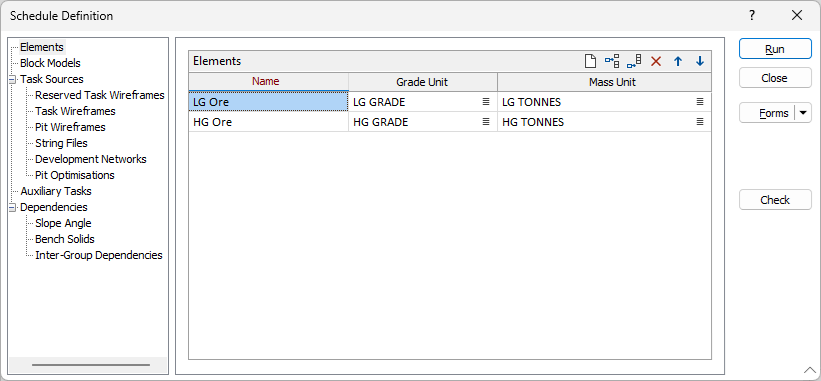

Elements

Element fields in each reference block model must now be mapped to the elements defined on a new Schedule Definition > Elements tab.

The new Elements tab allows for the definition of Scheduler element attributes that can be more easily interrogated and reported. The Units you can select are defined for the schedule on the Scheduling | Schedule tab, in the Attributes group.

Significant improvements have been made to the performance of Scheduling. Optimisation has been applied to saving schedules with large numbers of objects and building large numbers of dependencies. The resulting performance improvements have been measured as follows:

-

Bulk dependency creation: Five times (5x) increased speed.

-

Removal of redundant vertical dependencies: Two times (2x) speed increase.

-

Processing of validation steps during building of vertical dependencies: Approximately one and a half times (1.5x) speed increase.

-

Object model serialisation format change: Sixty times (60x) speed increase for large (>200,000 object) schedules.

For detailed information on the Scheduler, see Schedule

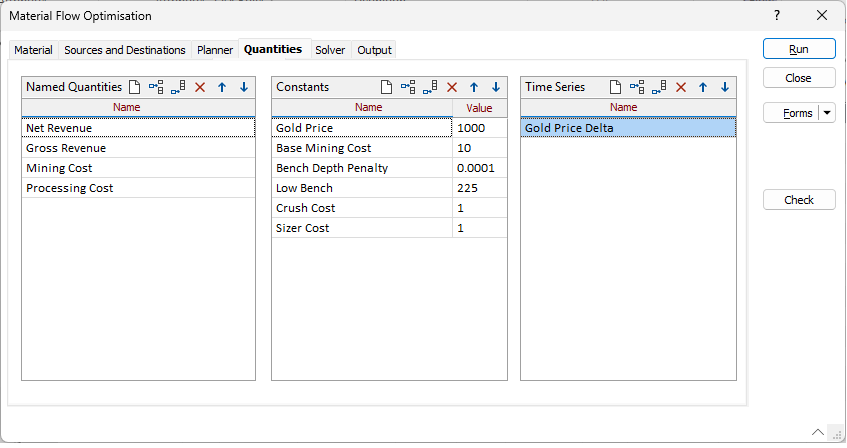

Optimise Material Flow

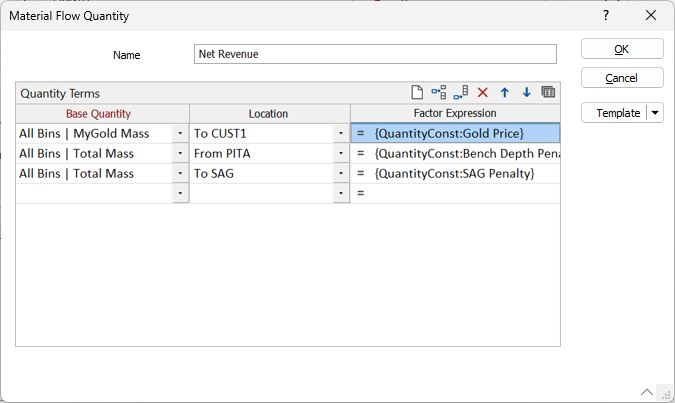

In Schedule > Optimise > Optimise Material Flow, you can now use a Quantities tab to define a single set of custom quantity definitions for both objectives and constraints.

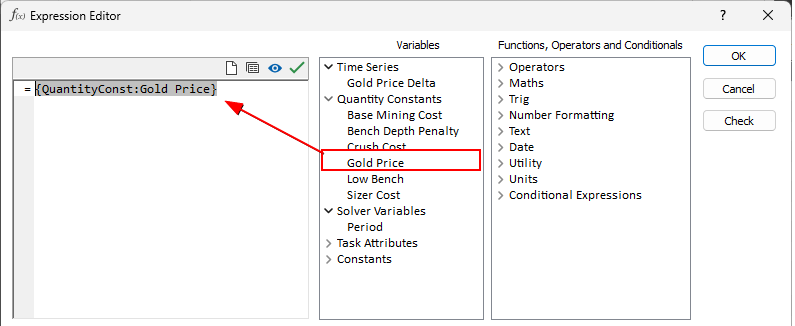

Factor Expressions

When you define a Material Flow Quantity, Named Constants and Time Series can now be used as variables in Factor Expressions:

Note that changing a Material Flow Quantity definition will update all Objectives or Constraints which reference a quantity of the same name.