Destination Scheduling

All of the concepts addressed during Source Scheduling including Processes, Equipment, Equipment Source Path, Dependencies and Constraints carry over to Destination Scheduling in some way.

The documentation for Destination Scheduling makes the assumption that you are familiar with the basics of Source Scheduling and that you have a Source Schedule (either from the project or an Input Schedule) to work from already. In a simple conceptual sense, Destination Scheduling takes material from a Leaf in your Source Table and places it in a Leaf in your Destination Table. The amount of material moved is called the Destination Quantity and is not necessarily the same amount as the related Source Quantity. In other words, when you work a Source Task you are removing material, when you work a Destination Task you are filling a space with material.

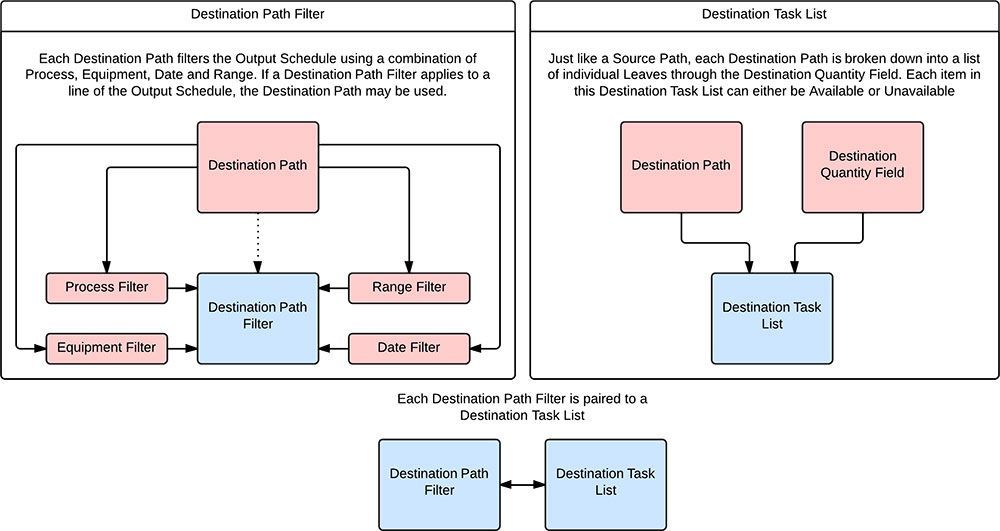

The primary difference between Destination and Source Scheduling is the way you think about paths. In Source Scheduling, you are controlling each piece of productive equipment which means that each Equipment has it's own Source Path. Destination Scheduling in comparison is a little different. In a truck shovel operation you may have 20 excavators but the location of the ideal Destination is more likely to be dependent on the location of the Source than each individual excavator. In this example you would have different Destination Paths that are Range dependent rather than Equipment dependent.

That doesn't stop you from having Equipment dependent Destination Paths but they are generally grouped into Equipment "types" rather than individually i.e. a Destination Path for ALL Dozers. In addition to Ranges and Equipment, Destination Paths can also be dependent on Processes and Date.

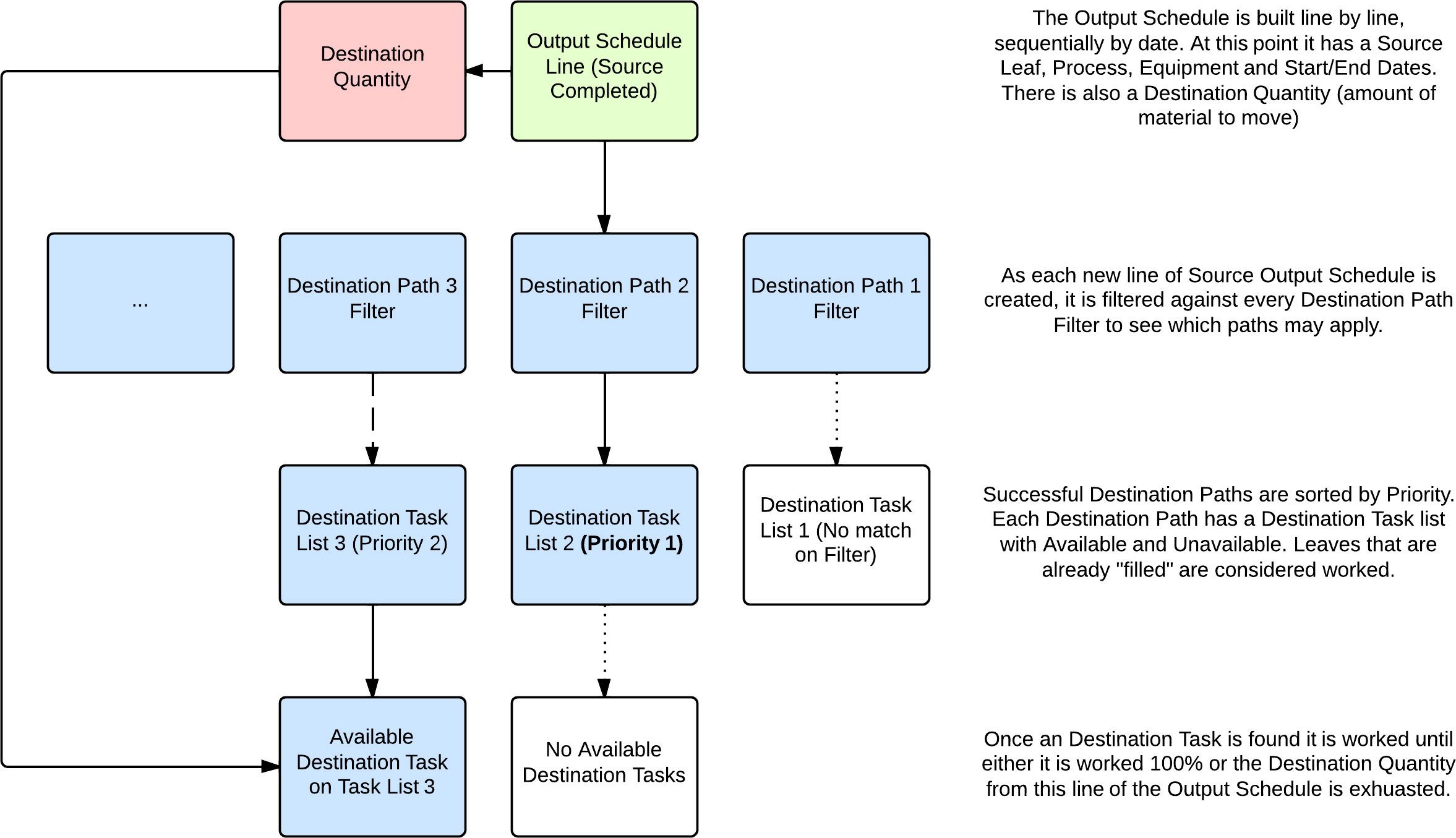

As each line of the Output Schedule is generated, the first part completed is the Source Schedule. Each partially completed Output Schedule Line is compared to each Destination Path Filter to see which Destination Task Lists may apply. Destination Task Lists are then (in order of priority) tested to see if there is a Released Destination to fill.

Effective use of Destination Paths themselves and Priorities are discussed elsewhere. See: Priorities

Practical

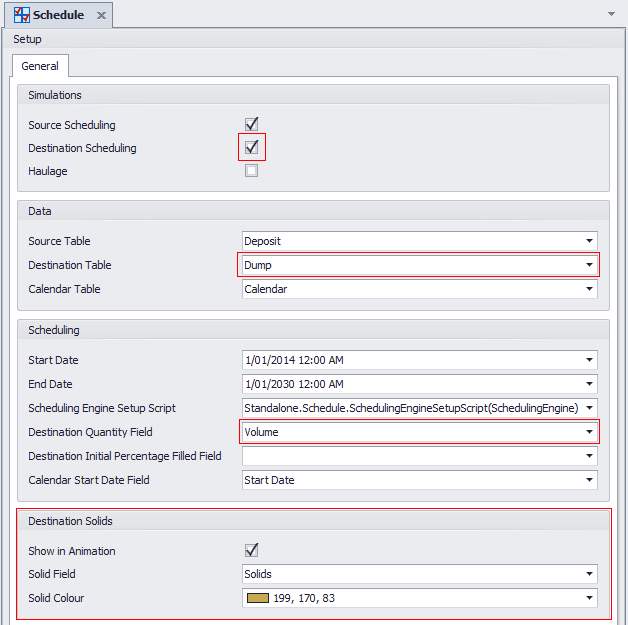

In order to run Destination Scheduling tick on the option in the Scenario Settings tab. Once selected on you will need to define the Destination Table, and which field defines the Destination Quantity (capacity) of each Leaf.

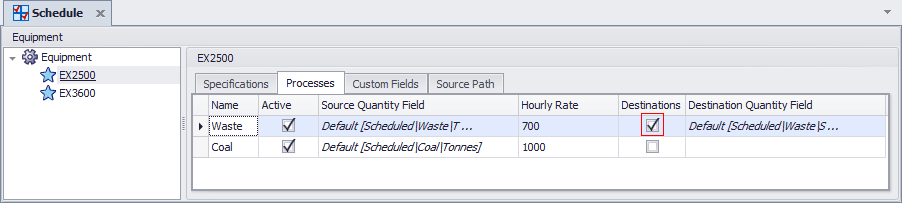

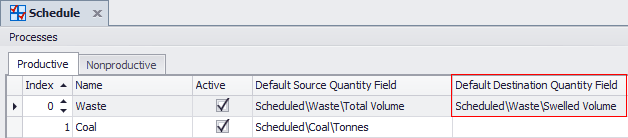

You may wish to set a Default Destination Quantity Field for each Process you are Destination Scheduling.

Each Process AND Equipment that you wish to use for Destination Scheduling also requires selection.

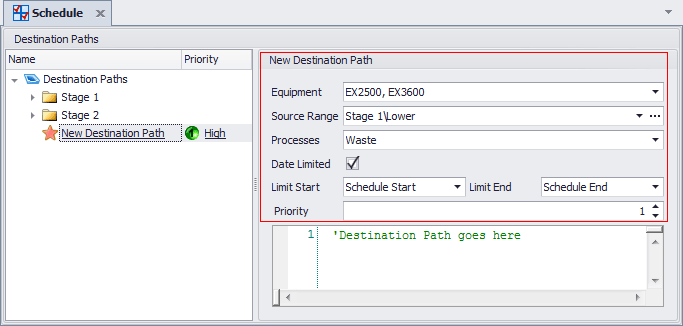

To create a new Destination Path right-click "Destination Paths" and choose Add -> New Destination Path. The five options before writing your Destination Path (the actual Path is addressed in the next section). The first four relate to your Destination Path Filter:

- Equipment (Default: All - Whitelist or Blacklist Equipment here)

- Source Range (Default: All)

- Process

- Date Limit

The final option is the Priority. See: Priorities