Materials Management

The Materials Management service tracks material as it progresses through the mining process. A movement of material (a source - destination combination) may be between a face and ore pass, between an ore pass to the crusher, or between the crusher to the mill. At each stage, as material moves between a source and a destination, it is associated with a grade and a quantity. The grade can be either an estimate or an analytical result; the quantity can be measured as truck dumps or as dump weights. As more definitive information becomes available, both the grade and the quantity values can be edited at each stage.

The final stage in the process is Reconciliation - the process of reconciling the grade and quantity of the material mined and moved during a period, against the grade and quantity of the material processed by the mill. It is a check of the actual against the claimed.

Prerequisites for Materials Management

Setting up the Reference Data

The following attributes must be configured in the Reference Data service to support Materials Management. Depletion Models and Grade Types are mandatory items which must be configured BEFORE you import location data.

- Flow Types (Primary, Intermediate, Surface)

- Depletion Models (Weighted Average, FIFO 100%, LIFO 100%)

- A record of the stock holdings of the locations (tonnes and grade)

- A record of the tonnes and grades at the ring/faces

- Whether the site needs to monitor for over bogging (by checking depletion of broken stock)

- Material Types (High Grade, Low Grade, Waste)

- Grade Types (Estimate,Survey)

- Elements (Gold, Silver. Copper etc.)

- Locations (consistently and uniquely named)

- Location Types (Stockpile, Backfill, Crusher, Orepass, Conveyor etc.)

- Grade thresholds, to record the minimum and maximum grade threshold for a particular location and element (as input to the Current Stocks chart).

- Element types are normally set up after installation and should not need to be maintained. Each element type is associated with an element measurement unit which is used to validate and display elements of that type.

- Material configuration includes items such as high grade ore, low grade ore, road base, backfill, etc. and each material item has a material type, ore or waste and so on.

- Grade Types are configured with an order, this allows processing to fall back to alternate grade types if the requested type has not been entered.

- Locations need to be managed as and when new locations are added, or when the properties of an existing location (Location type, Source or Destination etc.) change.

- The source and destination that are configured with a location type will determine how the addition or depletion is applied. Block depletion, for example, is processed differently to Stockpile depletion.

- If a transaction is submitted without a source or without a destination, then the location configuration is used to determine the defaults that will be used to complete the transaction.

Grade Control

Grade Control progresses as follows:

Prior to mining

The Configuration menu option is used to define the grade types and the measures that will be used in grade control. If estimated grades are being used, they can be entered for all primary locations using the Grades menu option or imported using the Import menu option. Estimates are usually derived from an ore body model.

On the day of mining

Assay sampling is undertaken and the analytical results are entered into the database.

Although estimated and assayed grades should be entered before mining starts, often this is not possible. If the assay results are not available prior to mining, they can be entered retrospectively by setting an entry date which is prior to the start of mining.

When mining begins, loaders extract material at the source locations and loading, hauling and dumping events are recorded in Data Acquisition. Material flow transactions, material movements from a source to a destination and their associated grades, are the quantifiable events upon which grade control is based.

At the end of current shift or before the start of the next shift

Checks are made to ensure that the data from the previous shift has been entered into the database, that all material movements and all necessary analytical results have been recorded for the ended (or the previous) shift. Any necessary edits or additions to the data are made.

The material movements and the stocks for the previous day are reviewed. Do the movements, stocks and grades match those reported by the mine control office? Are the quantities correct? Are the stocks valid? Are analytical results available with which to upgrade the estimates?

In Reporting, Daily Production and Movement Summary reports are generated.

End of Period Reconciliation

End-of-period stockpile surveys from the Surveyor are entered. Reconciliation reports and period production reports are run to reconcile planned values with actual (mill) values.

Reviews of planned verses actual results can result in changes to the ore body model, to work practices, and to schedules.

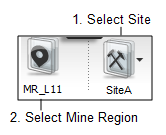

On the Services ribbon, click Materials Management to track material as it progresses through each stage of the mining life-cycle.

![]()

In the Materials Management workspace header:

- If Pitram is configured across multiple sites and mine regions, select the Site and Mine Region in which the Material Movements and Locations you will be working with are located:

All sites with more than one location have Mine Regions defined.

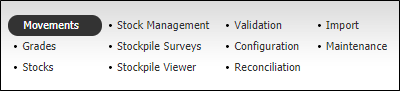

The following menu options are available on the service header. Movements is the default option:

- Material Movements. A view of movements (material flow transactions) for a defined period.

- Grades. Define and edit the estimate, assay and survey grades for the primary locations.

- Location Stocks. View movements into a location for the defined date-time. Stockpile surveys can be edited.

- Stocks Management. Manage stocks and grades for mine material.

- Stockpile Surveys. Enter end-of-period stockpile surveys.

- Stockpile Viewer. Graphical display of material at selected stockpiles or ore passes.

- Material Validation. A summary of validation errors that have occurred against movements or stocks.

- Materials Management Configuration. Define the way that grade types are used in the grade control process, the measures that are used and the permissions granted.

- Reconciliation. On screen reconciliation of actual against claimed tonnage and grade.

- Import Location Grades. To import either shift transactions or grades to make them available to Materials Management.

- Maintenance. Maintain the links and the data that are shared between Materials Management and Pitram