Reconciliation

Reconciliation is the process of reconciling the claims made by the mine (in respect of material tonnes and grade) with the actuals recorded at the mill.

Introduction

Before the end-of-period reconciliation process can begin, it is assumed that:

- A geologist has completed daily checks and ensured that all transactions have been entered correctly.

- A surveyor has surveyed the stocks, and their values have been entered using Stockpile Surveys.

- A senior geologist has reviewed end-of-period movements, grades and stocks, along with grade control and stockpile reports.

- The Envelopes required for reconciliation have been defined in the Reference Data service.

- A Tonnes_r (reconciled tonnage) attribute has been defined in the Reference Data service

What is an envelope?

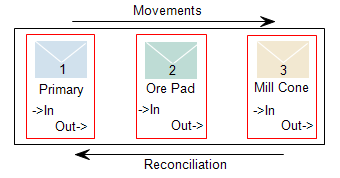

The concept of an envelope is central to the reconciliation process. An Envelope is a 'package of data' which consists of one or more locations, the movements in and out of those locations, and their stocks and grades:

Each envelope represents a stage in the material's journey from source to final destination. Each envelope has a name and an order number which defines its sequence.

An envelope must be defined in the Reference Data service before one or more locations can be assigned to it. LocA and LocB, for example, might be primary locations that belong to a Primary envelope; StockA and StockB might be stockpiles assigned to an Ore Pad envelope and so on:

It is the movements in and out of the envelopes that are reconciled. Using the simple example above, the reconciliation procedure would be to reconcile the Mill Cone envelope against the mill head grade end-of-period report, then balance the movements and the grade of the Ore Pad envelope, and then the Primary envelope.

Claimed versus actual

During the course of mining, loading, hauling and dumping events are recorded in the Pitram database.

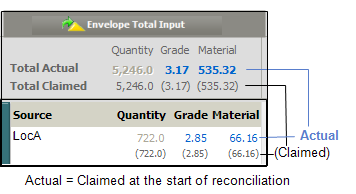

The sum of the material dumped at the locations of an envelope represents the claimed quantity and grade of the material moving into the envelope.

The sum of the material loaded and hauled from the locations of an envelope represents the claimed quantity and grade of the material out of the envelope.

Claimed values represent a 'best estimate' of the material mined. Initially, the actual values are set to be equal to the claimed values.

However, once the mill has reported the actual quantity and grade of the ore processed, a senior geologist will then adjust the actual values for each envelope.

Elements

Elements are configured in the Reference Data service (Groups | Materials Management | Element). Two attributes must be defined:

- Primary

- Unit of Measure

Primary

1 = the primary ore type

0 = not the primary ore type

At a gold-copper site, for example, gold is Primary = 1 and copper is Primary = 0. All other elements except the primary element are Primary = 0.

Unit of Measure

When working in Reconciliation, the grade type must be defined with a unit of measure that is either parts per million (ppm) or a percentage value (%).

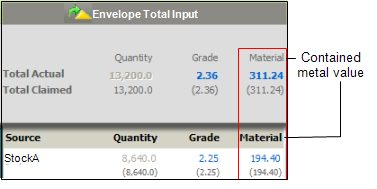

Contained metal

Contained Metal is a value calculated using the quantity, the grade, and the unit of measure (ppm or %) of an element. This gives a realistic value of the material for both claimed and actual values.

Parts per million (ppm)

The contained metal value is calculated in international troy ounces (ozs or t ozs):

| Where: |

| 1 troy ounces = 31.1034768g. |

| and where: |

| Material = (Quantity x Grade ) x 31.1034768 |

Percent (%).

The contained metal value is a percentage of the quantity.

| Where: |

| Material = (Quantity x Grade) / 100 |

The unit of measure for a grade type is defined in Materials Management Configuration. For the published reconciliation data to be made available for reporting, a Tonnes_r (reconciled tonnage) measure should be set up in the Measures table.

Information on using the Reconciliation service is contained in The Reconciliation window.