Materials Management Configuration

Select Configuration from the Materials Management menu, to set a number of configuration options that determine how materials and grades are processed by Pitram.

The locations, elements, envelopes and flow types that will be used in the grade control process, must be configured using the Materials Management Configuration.

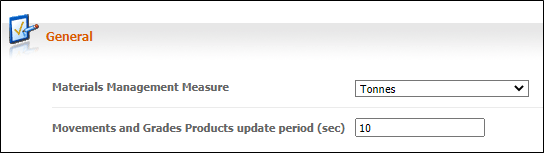

General

Materials Management Measure

Select the primary measure for material movements.

For the published reconciliation data to be made available for reporting, a Tonnes_r (reconciled tonnage) measure should be set up in the Measures table.

You can enter the Movements and Grades Products update period, in seconds, in the field provided.

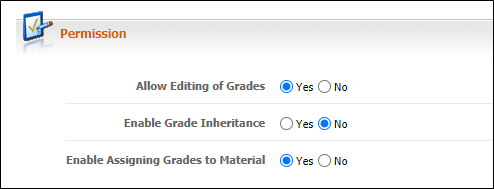

Permission

Allow Editing of Grades

Select this option to allow the grades displayed in the Grades screen to be edited. When you edit grades, they will only be updated in the Portal transactions database.

Enable Grade Inheritance

If this option is selected, elements will inherit the previous grade entered (if any) when a movement is made out of a location and the element grade is left blank. If this option is turned off, the grade value will remain blank.

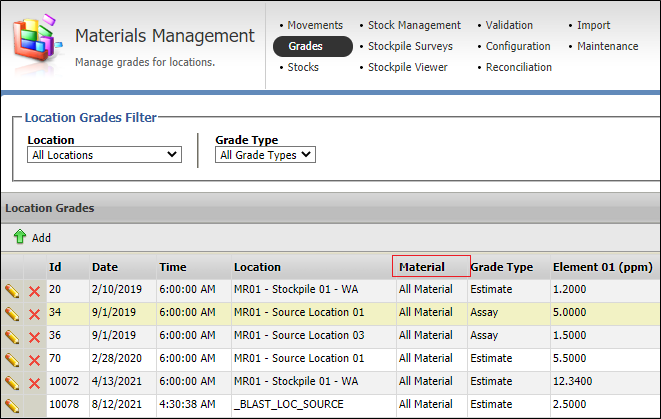

Enable Assigning Grades to Material

Select this option to allow grades to be entered against a location-material combination. When this option is selected, an extra column in the grade entry screen allows the Material to be selected for a primary location.

The propagation of grades to movements with the same location-material combination is supported, as is the entry of a NULL grade.

By selecting "All Material" the grade is applied to all movements (from that point in time) regardless of material. Movements will use the latest matching material-location combination grade unless a more recent “All Material” grade is found. If neither of these cases are found, then the movement will have no grade.

Note: The Enable Assigning Grades to Material option is not supported for Drill and Blast enabled configurations, and will not be displayed.

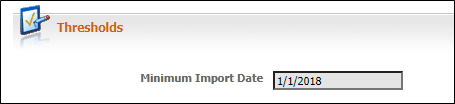

Thresholds

Thresholds are the limits that are applied to the depletion of a stockpile.

Minimum Import Date

The import of shift data into Materials Management is handled by an automated import facility. It is also possible to manually import site data using the Import option on the Materials Management menu.

The process for setting up the Automated Shift Import facility is as follows:

- Set the Minimum Import Date under Thresholds in the Materials Management Configuration screen.

-

Create a directory in the following location:

<server>\Program Files\Micromine Pty Ltd\PortalConnector\Config\<Site>\Pitram\Notification

where <Site> is the Pitram site which contains the shift data to be imported.

-

On the release CD there is a file called NotificationCommandSet.xml located in the directory: Portal Extras\Materials Management Notification. Copy this file to the directory you created in Step 2.

-

Restart the Portal Connector service in order to activate the Automated import. Shift data will be imported from the date of the Minimum Import Date up to the date of the most recent shift.

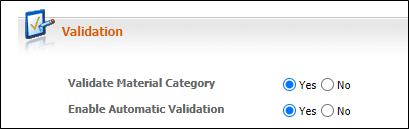

Validation

The way that the Materials Management data is validated will depend on the Validation options you configure here.

Validate Material Category

Select this option if you want to validate material categories.

Enable Automatic Validation

Select this option if you want Pitram to automatically validate the transactions entered into Materials Management.

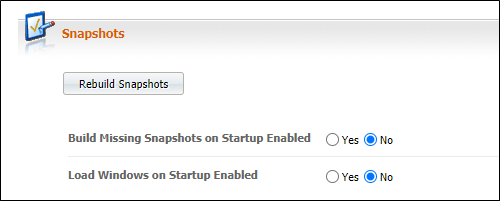

Snapshots

The Materials Management service provides access to the snapshots of inventory levels recorded as part of the events related to the running of a mine by the Data Acquisition application. The options in the Snapshots section of Configuration are used to configure the available snapshots.

Rebuild Snapshots

Click the Rebuild Snapshots button to refresh and recreate the Materials Management snapshot.

Build Missing Snapshots on Startup Enabled

Select this option if you want any snapshots that are missing from Materials Management to be built automatically when Pitram is started.

Load Windows on Startup Enabled

Select this option if you want Materials Management to rebuild the Snapshot window definitions on startup.

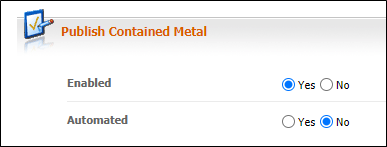

Publish Contained Metal

Enabled

Select this option if you want to enable the publication of contained metal.

Automated

Select this option if you want to automate the publication of contained metal.

Chainage

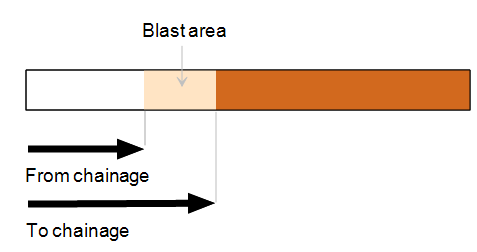

When chainage measures have been recorded for a location, and when movements of material from that location have been recorded, From Chainage and To Chainage columns are displayed in the Material Management | Movements screen. The grade of the material moved is automatically updated to reflect the grade entered for the corresponding chainage measure.

After each blast, an average is taken from the material in the blasted area. This average grade is assigned to all ore movements coming from that location until the next blast.

- From chainage is the metres advanced from the start of the drive to the face before the initial or last blast.

- To Chainage is the metres advanced from the start of the drive to the face after the last blast.

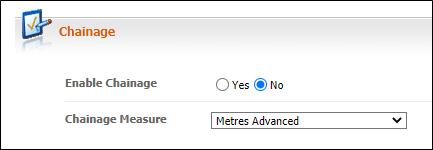

Configuring Chainage

Chainage is configured in Materials management -> Configuration. At the bottom of the screen, select Yes to enable Chainage, and select the Chainage Measure. The measure must be one that is configured both for locations and as a cumulative measure.

Stockpile Surveys

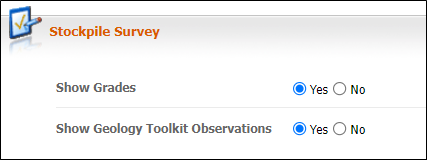

The Stockpile Surveys options determine the display of Grades and Observations in the Stockpile Surveys screen.

Show Grades

Grades configured in the Grades screen will be displayed in the Stockpile Surveys screen if the Show Grades option is set to Yes.

Show Geology Toolkit Observations

Published Observations are available in the Materials Management Stockpile Survey screen, but are not enabled by default. To enable the display of observations, in the Materials Management Configuration screen, set Show Geology Toolkit Observations to Yes.

Save Configuration

Finally, click the Save Configuration button to save the changes you have made.