Material Movements

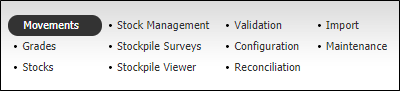

The ![]() Movements menu option is selected by default whenever you open the Materials Management service and can be used to track material flow transactions throughout the mine. You can also modify grades as the material moves through various processing stages.

Movements menu option is selected by default whenever you open the Materials Management service and can be used to track material flow transactions throughout the mine. You can also modify grades as the material moves through various processing stages.

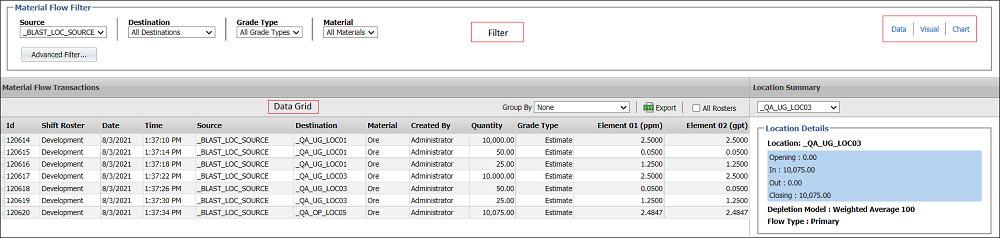

Material flow transactions can be viewed according to their Start Date, End Date, Source and Destination. They can be viewed as a data grid, as a schematic diagram, or as a chart. The links between transactions can also be displayed.

By default, transactions are displayed in a data grid. Which transactions are displayed depends on the criteria you select in the Material Flow Filter pane, and (optionally) in the Apply a Filter.

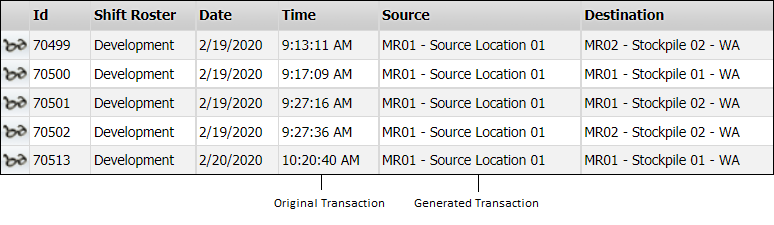

Generated transactions

There may be occasions when material is moved to a 'holding' stockpile before it is moved onto a main or other stockpile. The system can be configured to complete both transactions (movements) at the same time.

For example, Truck1 dumps high grade ore at a Holding Stockpile and returns to Loader1. At the same time, another transaction is automatically generated to move the high grade ore from the Holding Stockpile to the Main Stockpile.

View Options

A number of View options are available for selection:

- View a schematic. A schematic of the movements undertaken during the period.

- View a chart. A bar chart presentation of the material movements.

- View transaction links. A schematic of multiple source-destination movements that have occurred during the defined period.

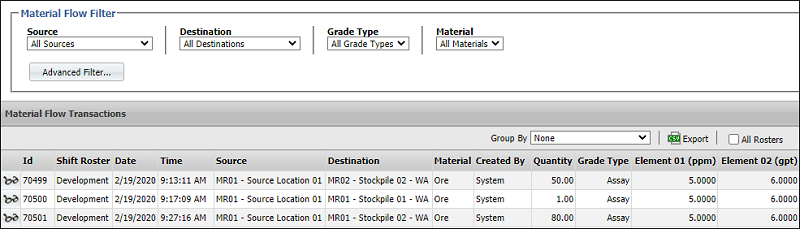

By default, transactions are shown in a Data grid:

You can manipulate the rows of the grid in the following ways:

|

Accept None or select an option to Group the transactions in the data grid by Destination, Material, Source, Source Destination or Shift, Source, Destination. |

|

Export all transactions to a CSV file. By default, the file name is MaterialFlow.csv |

|

Select the check box to display data from all shift rosters. |

|

Select a location to display data for from the drop down. |

You can also use the option to the left of each row to quickly view the details of that transaction:

|

|

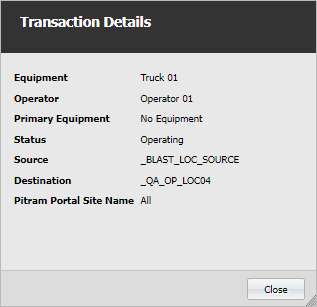

View the details of this transaction - the primary equipment (loader) and the secondary (haul truck) equipment, the operator, and the status.

|

The following columns are displayed for each record:

ID

A system identifier that uniquely identifies the material flow transaction. If a transaction already exists with the same ID, it is replaced. This occurs when the Materials Management data is reprocessed. System identifiers allow more detail about a transaction to be reported. In the case of Pitram, for example, which unit of equipment was used to move the material, who was operating that equipment etc.

Shift Roster

The name of the configured Shift Roster on which the material movement occurred.

Date/Time

The Date and Time the material movement occurred.

Source

The location where the material is mined or sourced.

Destination

The location where the material is dumped or stockpiled.

Material

The (Waste, Low Grade Ore, High Grade Ore etc.) material classification.

Created By

The user name of the user who was responsible for the material movement data entry.

Quantity

The amount of material moved using the units of measure applicable to that material type.

Grade Type

The configured grade type for the material in the movement instance.

Elements

A column is included for each of the Grade Control | Elements that have been configured in Pitram for your site using the Reference Edit service.

Chainage

When chainage measures have been recorded for a location, and when movements of material from that location are recorded, From Chainage and To Chainage columns are displayed in the Material Management | Movements screen. The grade of the material moved is automatically updated to reflect the grade entered for the corresponding chainage measure.

Refer to the Chainage topic for more information.