Chainage

A Chainage Configuration option allows for grades in the Materials Management Grades and Movements screens to be surveyed and reported based on a Chainage (total metres advanced) measure.

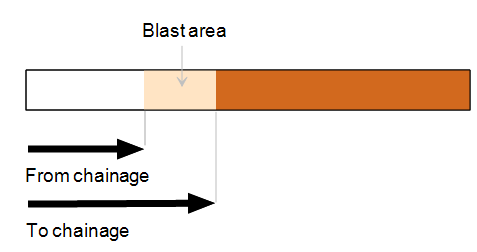

After each blast, an average is taken from the material in the blasted area. This average grade is assigned to all ore movements coming from that location until the next blast.

- From chainage is the metres advanced from the start of the drive to the face before the initial or last blast.

- To Chainage is the metres advanced from the start of the drive to the face after the last blast.

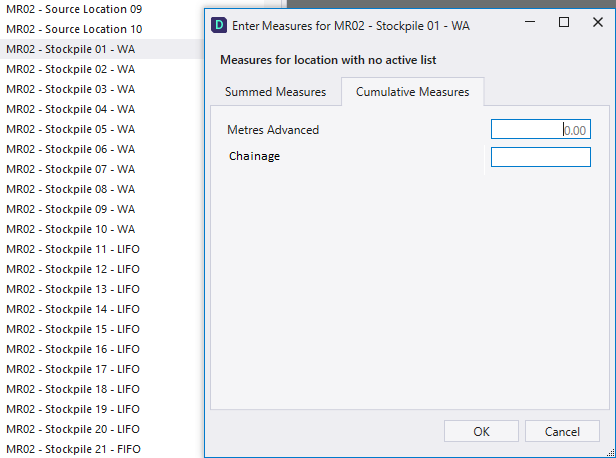

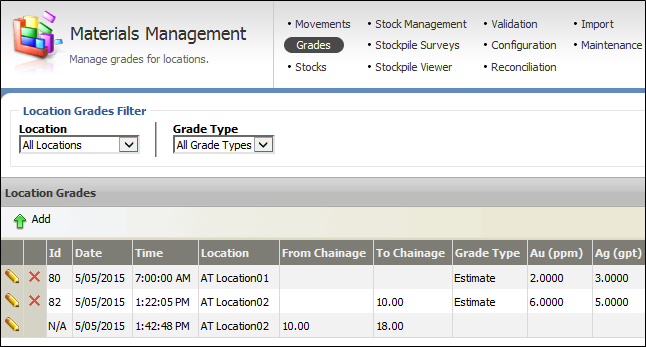

Once Chainage measures have been configured and enabled, when you right click on a location in Data Acquisition and record a Cumulative measure, a record is added to the Material Management | Grades screen. This allows assay grades values to be entered against a defined chainage.

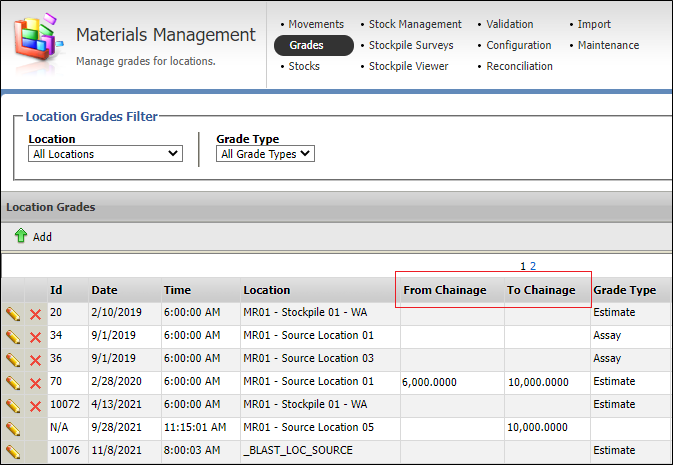

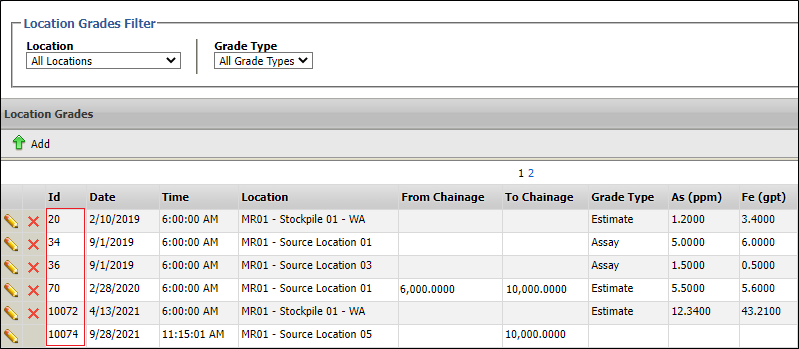

When Chainage is enabled as part of the configuration of the Materials Management Service, From Chainage and To Chainage columns are displayed in the Grades screen.

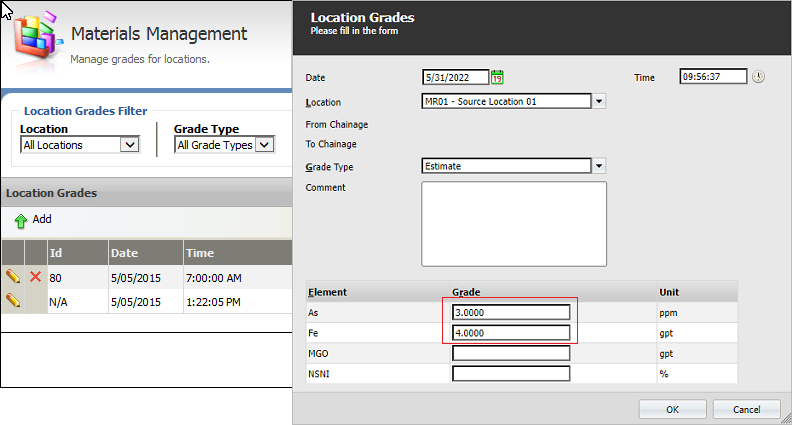

At this stage no movements from the location have been recorded, however we can click on the Edit button to enter grade values for the Chainage measure:

Once grades are entered, the Chainage measure event is given an ID:

The Grades screen is updated as more Chainage measures are recorded:

Once grades are entered for a Chainage measure in the Material Management | Grades screen, those grades will still exist in the system, even if you subsequently edit the shift and remove the Chainage measure event.

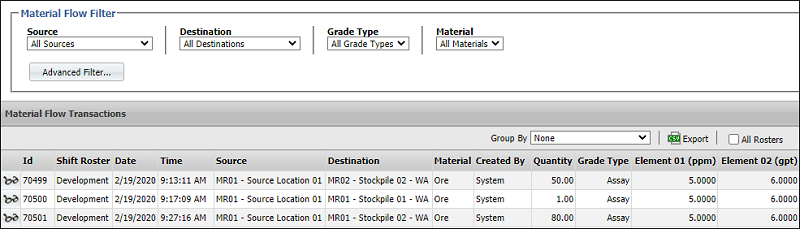

When chainage measures have been recorded for a location, and when movements of material from that location are recorded, From Chainage and To Chainage columns are displayed in the Material Management | Movements screen. The grade of the material moved is automatically updated to reflect the grade entered for the corresponding chainage measure.