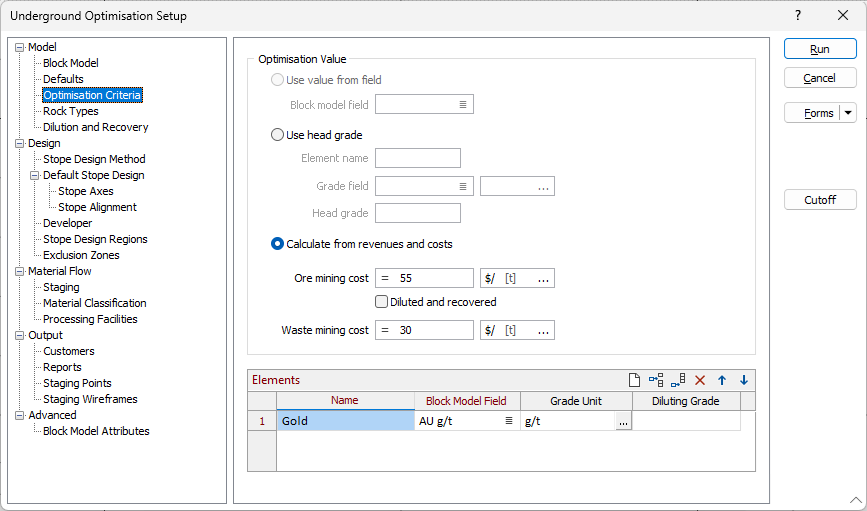

Optimisation Criteria

Optimisation Value

The optimisation value for a block is the value assigned to it for the purposes of the optimisation. If the optimisation value is positive, including the block in a solution increases the value of that solution; conversely, if the optimisation value is negative, including the block decreases the value of the solution.

Unfortunately, it is often necessary for negatively valued blocks to be included to ensure that the requirements of the design are met. The role of the optimiser is to maximise the number of positively valued blocks in the solution whilst minimising the number of negatively valued blocks that must be included to satisfy the requirements of the design.

Select the method to be used to assign the optimisation values to the blocks:

Use value from field

Select this option to assign the optimisation value for the blocks from a field in the block model.

Selecting this will disable the Mining Costs and the Elements group (below) and also the following tabs that support the integrated material flow model:

- Setup > Model > Material Flow (Material Classification, Processing Facilities, Customers)

- Setup > Model > Rock Types

- Setup > Model > Dilution and Recovery

Block model field

Select the Value field in the block model file from which the optimisation value for each block should be sourced.

For the purposes of the optimisation, sub-blocked models are regularised automatically as required. If the optimisation values are sourced from a field in the block model, the optimisation values for the regularised blocks are calculated by summing the optimisation values from the constituent sub-blocks. However, it is not meaningful to sum some types of values (such as grades). To overcome this, an expression should be used to convert the values to a quantity that can be summed to produce a meaningful result that is comparable to the values assigned to other blocks of the regularised size.

For example, for each block (and sub-block), the element grade can be multiplied by the mass of material to produce the mass of the element, which can then be added to the masses of the element in the other constituent sub-blocks to produce the total mass of the element in the regularised block. It is meaningful to compare (and sum during the optimisation) the total masses of the element in the regularised blocks.

Tip: The volume of a block can be calculated using the following expression:

[_EAST] * [_NORTH] * [_RL]

Example: If the “Au” field specifies the grade of gold in grams per tonne (g/t), and the “Density” field specifies the density of the material in the block in tonnes per cubic metre (t/m3), the following expression would apply a cutoff grade of 0.5g/t and return the mass (g) of gold in the (sub-)block:

if [Au] < 0.5 then 0 else [_EAST] * [_NORTH] * [_RL] * [Density] * [Au] endif

Use head grade

Select this option to select the stopes based on the head grade of the first element defined on the Elements grid (below), which is referred to as the “primary” element.

Selecting this will disable the Mining Costs (below) and also the following tabs that support the integrated material flow model:

- Setup > Model > Material Flow (Material Classification, Processing Facilities, Customers)

- Setup > Model > Dilution and Recovery

Stages will be parameterised by a range and increment of head grades and the label for Design | Staging > Generate Incremental Designs > Stage Generation > Revenue Adjustment Factor will be changed to “Primary Element Cutoff”.

(Head grade)

Enter the lowest head grade that should be accepted in a stope.

Calculate from revenues and costs

Select this option to calculate the optimisation value for each block from the parameters supplied for the integrated material flow model.

To refine this, you can also set Setup > Model > Optimisation Criteria > Elements >Grade Representation = BLOCK VALUE to specify that the value assigned to the element is the revenue that will be derived from the block for that element. As with the other Grade Representation options, the applicable costs will be calculated for the block and subtracted from the element value to arrive at the net revenue derived from the element for the block, which is included in the optimisation value for that block.

Optimisation values for all blocks (and sub-blocks where applicable) are calculated on the basis that it is possible to mine and process the blocks selectively. If the reality is that high-grade (sub-)blocks will be mixed with surrounding low-grade blocks during mining, on the Block Model tab, in the Reblock Model group, the Regularise option should be used to regularise the model prior to using the Stope/Pit Optimiser. This will ensure that:

- if material bins are defined, the material will be assigned to those bins based on the values of the attributes after mixing, and

- the expected mass of attributed mixed material is sent to the processing facilities.

Ore mining cost

Specify the cost per unit mass or volume incurred when mining a block as ore. This is the cost of blasting, mining and haulage of ore.

Ore Units

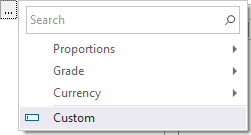

Select the Volume or Mass unit of measurement from the menu opened by clicking the ellipsis.

If you select Custom from the menu, expressions can be used to vary the cost by the depth of mining and/or the distance of the block from the plant.

Diluted and recovered

Select this check box to specify that the mining cost for ore applies to the ore mass (or volume) after mining dilution and recovery has been included, and not to the in situ ore mass (or volume).

Waste mining cost

Specify the cost per unit mass or volume incurred when mining a block as waste. This is the cost of waste blasting, mining and haulage. This cost is applied to the recovered material. (Dilution is not applied to waste.)

Waste Units

Select the Volume or Mass unit of measurement from the menu opened by clicking the ellipsis.

If you select Custom from the menu, expressions can be used to vary the cost by the depth of mining and/or the distance of the block from the plant.

Elements

The Elements grid is disabled when the Optimisation Value: Use value from field check box is selected (above).

Elements are recovered from material bins by processing facilities, after which they can be sold to customers.

Elements should be defined for any of the following purposes:

- Specifying the outputs from processing facilities.

- Specifying and reporting the grades of stockpiles.

- Producing breakdowns of volumes, masses, grades and revenues by element in Optimisation Results and Extractions reports.

Use the Elements grid to specify the list of elements produced from the mine, along with the following settings for each one:

Name

Enter the name of the element produced.

This name is also used to build names for fields in report data sources and attributes for saved wireframes.

Block Model Field

Select the field in the block model file from which the element grade for each block should be sourced.

An expression can be used to apply a cutoff grade to the element.

Example: If the “Copper” field specifies the percentage of copper by mass, the following expression would apply a cutoff grade of 0.35% and return the percentage of copper to be used for the (sub-)block:

if [Copper] < 0.35 then 0 else [Copper] endif

Grade Representation

Click the ellipsis to select the units in which the element grades are specified.

Custom units not presented in the list are accessible from the Units selection context menu, where available, by clicking the ellipse button, pressing F3 or by right clicking in the field.

You can use the Search field to find the required unit, including any Custom units.

All available Grade units are supported, as well as the following:

| Grade Representation | Description |

|---|---|

| % mass | Percentage of block mass represented by element |

| ct/t | carats (1 carat = 0.2 grams) per tonne |

| g/t | grams per tonne |

| kg/t | kilograms per tonne |

| dwt/t | pennyweights per (metric) tonne |

| ozt/t | Troy ounces (1 Troy ounce = 31.1034768 grams) per (metric) tonne |

| lb/t | avoirdupois pounds (16 ounces = 1 pound) per (metric) tonne |

| USER GRADE | Mass of element in block is calculated by multiplying specified value by mass (density * volume) of material in block without conversion. Useful for processing obscure combinations of units. |

| BLOCK VALUE | Expected revenue, after selling costs (which are proportional to mass of element, which cannot be determined), for block. Optimisation value for block is calculated by subtracting all other applicable costs from specified value. |

Diluting Grade

Specify the grade of the element to be assigned to material added as dilution.

If this value is not specified, then the diluting grade for the element is set to zero (0).