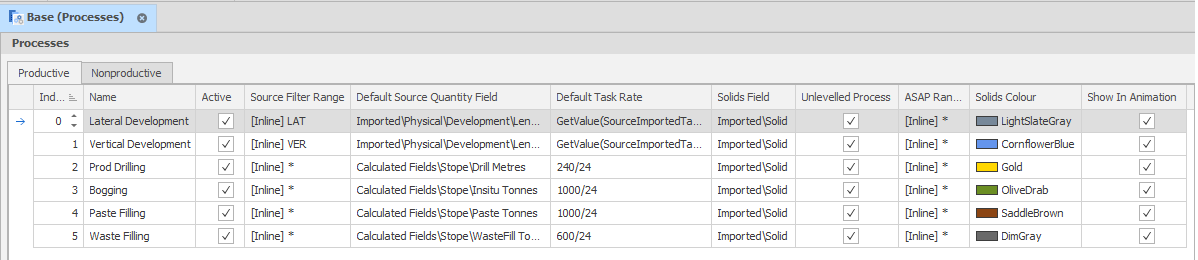

Processes

A Process is any activity a piece of equipment may undertake that should be scheduled and reported separately from others. Processes are either productive (linked to a data value such as tonnes or metres) or non-productive (representing a pause in activity such as a public holiday or maintenance).

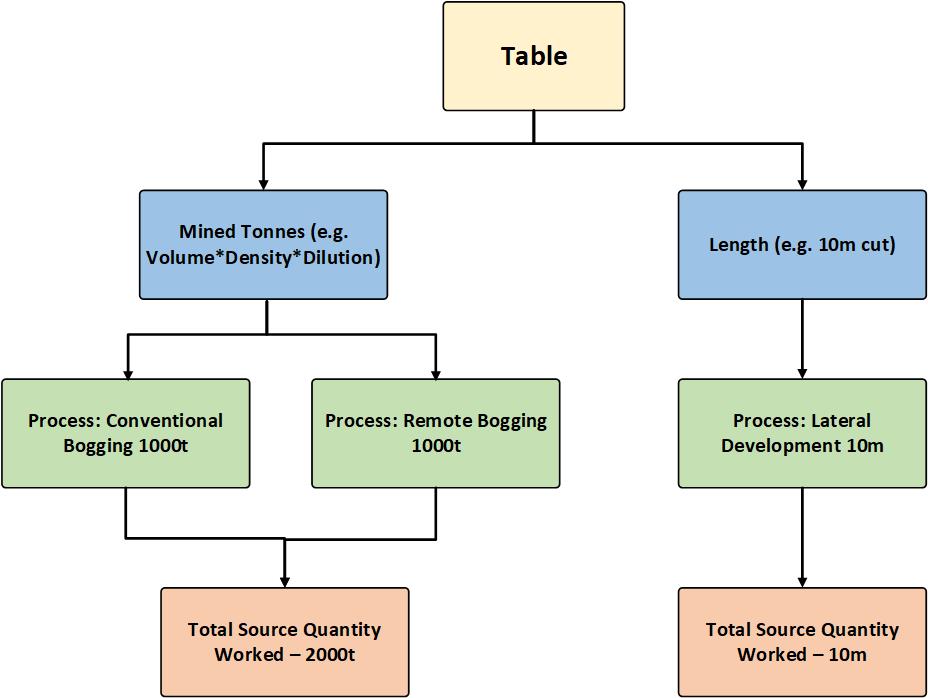

Every productive process has a value that is linked to a Field in the Deposit Table. Source scheduling is based on "working" this value, which is called the Source Quantity. Note that two or more different processes may use the same Field for their Source Quantity, however the value is duplicated, not shared.

Any Leaf in the Deposit Table that has a Source Quantity greater than zero can be worked. The most work that can be done on any Source Quantity is 100%.

The following Source Quantity Fields are automatically created during the tunnel and stope generation processes:

-

Volume: Solid Cubic Metres.

-

Length: Length in Metres of Tunnel cut.

Note that you don't have to schedule Ore by Volume or Tonnes, it's possible to schedule with something else, depending on your scheduling requirements. A Source Quantity field can be a calculated field that uses other metrics in its expression.

Anywhere from 0% (default) to 100% of each productive process can be pre-scheduled (per Leaf). Assigning an Initial Percentage Completed Field reconciles your Data with any material that has already been mined to ensure you are only scheduling material that is still in the ground.

Any Leaf that can be worked (has a Source Quantity greater than zero) can also be displayed visually through the use of 3D Solids by assigning a Solids Field to the process. This means that Leaves that cannot be worked (volume <=0) will not be displayed even with an associated Solid field. Any pre-schedule will also apply to the way each Solid is displayed (50% pre-schedule = 50% visible, 100% pre-schedule = 0% visible).

By default, users should use the Solid field that is created during the Stope and Development solid generation step.

The combination of a Process (including its assigned Source Quantity) and each workable Leaf is known in the application as a Task. Scheduling can be considered to be the assignment of each of these Tasks to one or many pieces of Equipment.

![]()

In the Workflow Pane, you can also navigate to this function as part of your Scheduling Advance Default Workflow.

Example Productive Processes:

- Horizontal Development

- Vertical Development

- Production Drill

- Bogging

- Paste Fill

- Waste Fill

Example Non-productive Processes:

- Maintenance

- Public Holiday

- Delayed Start

Add Process

Click the Add Process button to add a Productive or a Non-productive process (depending on the tab currently selected in the Processes Setup window).

You can also use the tools on the local toolbar to manage the list of processes:

|

|

Add a new item to the list. |

|

|

Delete the item(s) currently selected in the list. |

|

|

Move the currently selected item(s) Up to reorder the list. |

|

|

Move the currently selected item(s) Down to reorder the list. |

|

|

Use the Bulk Editor to make bulk modifications to the items in the list. |

|

|

Use a Wizard to semi-automate the process. |

Specify the following fields and parameters:

Name

The name of the Productive or Non-productive process.

Active

In order to undergo any kind of simulation, a Productive Process must be set as Active.

Source Filter Range

Set the Source (Text Range or [Inline] *) Range that applies to the Tasks. See: Text Range and Inline Ranges.

Default Source Quantity Field

For Source Scheduling, link to a Double Precision Float Field type.

It is possible to not choose a Default Source Quantity Field, but this will require each piece of equipment that works this process to have a Source Quantity Field explicitly assigned.

Default Task Rate

The Default Task Rate determines the rate that should be used by equipment if none is specified. The Default Task Rate is also used in conjunction with Unlevelled Process activation. When the Unlevelled Process check box is ticked, the default task rate becomes the rate at which the solid is depleted without the need of adding equipment.

Default Destination Quantity Field

For Destination Scheduling, link to a Double Precision Float Field type.

It is possible to not choose a Default Destination Quantity Field, but this will require each piece of equipment that works this process to have a Destination Quantity Field explicitly assigned.

Solids Field

Link to a Solid Field type.

Any Leaf that can be worked (has a Source Quantity greater than zero) can also be displayed visually through the use of 3D Solids by assigning a Solids Field to the process. This means that Leaves that cannot be worked (volume <=0) will not be displayed even with an associated Solid. Any pre-schedule will also apply to the way each Solid is displayed (50% pre-schedule = 50% visible, 100% pre-schedule = 0% visible).

By default, users should use the Solid field that is created during the Stope and Development solid generation step.

Unlevelled Process

The Unlevelled Process setting is used in conjunction with the Default Task Rate. When the Unlevelled Process check box is ticked, the default task rate becomes the rate at which the solid is depleted without the need of adding equipment.

Unlevelled tasks do not get worked on by conventional equipment. Instead, it is guaranteed that they will always be worked on as soon as they are ready (when the ASAP Range is set to all *).

When ASAP range is set to all tasks (*), the solids will be depleted as soon as possible, only honouring the established sequence. When tasks are not in the ASAP range, they become ALAP. These solids will be depleted as late as possible in the schedule. For example, if a stope is dependent on an ALAP tunnel, the tunnel will only be depleted just before the starting date of that stope.

ASAP Range

ASAP Range determines which unlevelled tasks should be completed “As Soon As Possible". If a task is not in the ASAP range, then it will be completed “As Late As Possible" (ALAP) instead, without delaying any ASAP tasks.

Solids Colour

Click on the colour patch or the drop-down arrow to set standard or custom colours for your productive process solids. These colours are shown anywhere a process is selected.

Show in Animation

Select or deselect the check boxes to show or hide processes in the Animation Window.

Right-click in the header to access common grid functions:

-

Best Fit makes the best use of the column space.

-

Best Fit (all columns) makes the best use of the available space.

-

Use the Column Chooser to access additional columns and drag them into the headers.

-

Show/Hide Column options

-

Show/Hide a Find Pane to search the grid list.

-

Show/Hide Auto Filter Row to filter the grid list

-

Show/Hide Group By Box to group list items