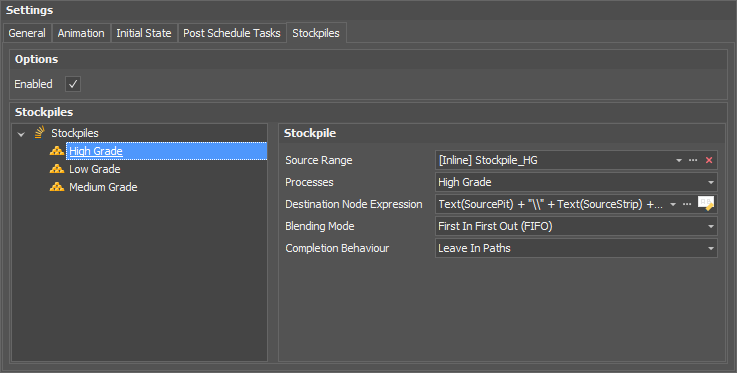

Step 8: Stockpile Settings

To access the feature, open a scenario, go to Settings and then select the Stockpiles tab.

Click “Enabled” and create a new Stockpile.

Step 8.1: Source Range

Select the range of nodes from your Source table that will make up the stockpile.

Step 8.2: Processes

Select which processes can remove the stockpiled material.

Step 8.3: Destination Node Expression

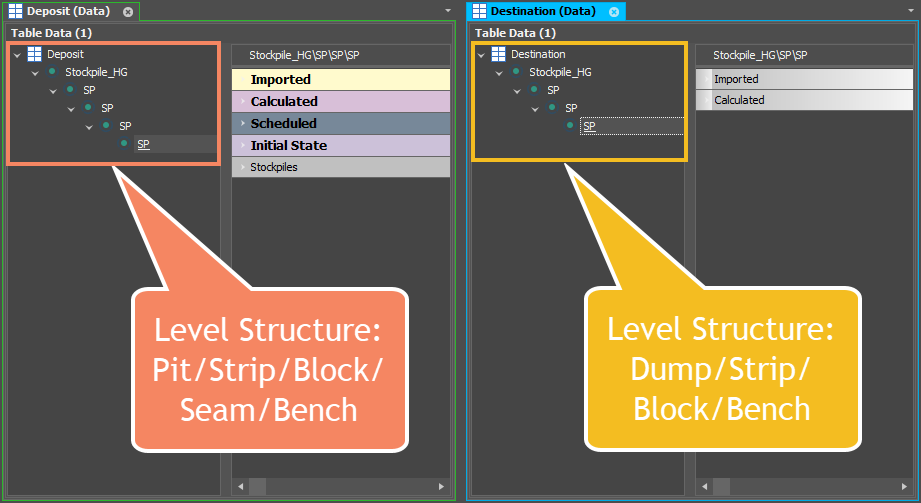

The stockpile works by linking records between the Source and Destination tables. A link between two records is formed if they have the exact same address. The Destination Node Expression uses the address of a Source table record as an input, modifies the address based on the expression and then searches the Destination table for a record matching the output address.

In the example above, the Source table has five levels that make up its table structure whereas the Destination table only has four. Because the positions are named exactly alike at each shared level we can take the address of the Source record and discard the Seam level to create the exact address of the Destination record.

To match the two addresses in the example above we use the following node expression:Text(SourcePit) + “\” + Text(SourceStrip) + “\” + Text(SourceBlock) + “\” Text(SourceBench)

Step 8.4: Blending Mode

Blending Mode refers to how the application treats material that is removed from a stockpile. Depending on the Blending Mode selected, when material is taken from the stockpile it is removed either:

-

in the order it was deposited,

-

in the reverse order in which it was deposited, or;

-

as an averaged product of all material currently on the stockpile.

-

First In First Out

-

Material deposited to the stockpile before some other material will be removed before that material

-

-

First In Last Out

-

Material deposited to the stockpile before some other material will be removed after that material

-

-

Blend

-

Simulates stockpiles in which material of various qualities are blended

-

Material is removed from the stockpile based on a weighted-average of the constituent materials of the stockpile

-

Step 8.5: Completion Behaviour

Completion behaviour refers to how the application treats stockpile tasks. A completed stockpile task is any schedule step in which a piece of equipment works a process from the stockpile. Importantly, a completed task does not necessarily mean that the equipment has worked all the material.

For example:

-

The equipment has been directed to dig 100 tonnes from the stockpile.

-

There are 20 tonnes available on the stockpile at the time the equipment commences its task.

-

The schedule step will report the equipment digging 20 tonnes.

-

The task is now considered completed and will be removed or left in the equipment's path depending on the selected Completion Behaviour.

-

Leave In Paths (default)

-

Completing a stockpile task does not remove it from the equipment’s Source or Destination Path.

-

When material relevant to the path becomes available the equipment will work it until the full quantity specified in the path has been worked.

-

(If no quantity is specified in the path, the full quantity on the Source table record is the amount that will be worked.)

-

Remove From Paths

-

This option is most commonly used for tasks that occur only once, such as the creation of a rehandle bridge and its later removal.

-

Once a task has been completed (as defined earlier), it is removed from the path of the associated equipment and will no longer be worked by that equipment.

-

This option is typically used in conjunction with dependencies to trigger the stockpile event so that the full task can be worked.

-