Optimal Pit Analysis

Optimal pit shell analysis is the analysis of the ore reserves, waste tonnage, metal production and cash flow for each of the nested pit shells. The ore reserves in each nested pit shell are calculated using a fixed metal price.

The analysis of nested pit shells allows the optimal pit shell to be selected, and the future discounted financial cash-flow to be determined, taking into account the discount rate and other parameters such as recurring expenses.

Three methods can be used to determine the mining sequence for the pit shells:

Best case

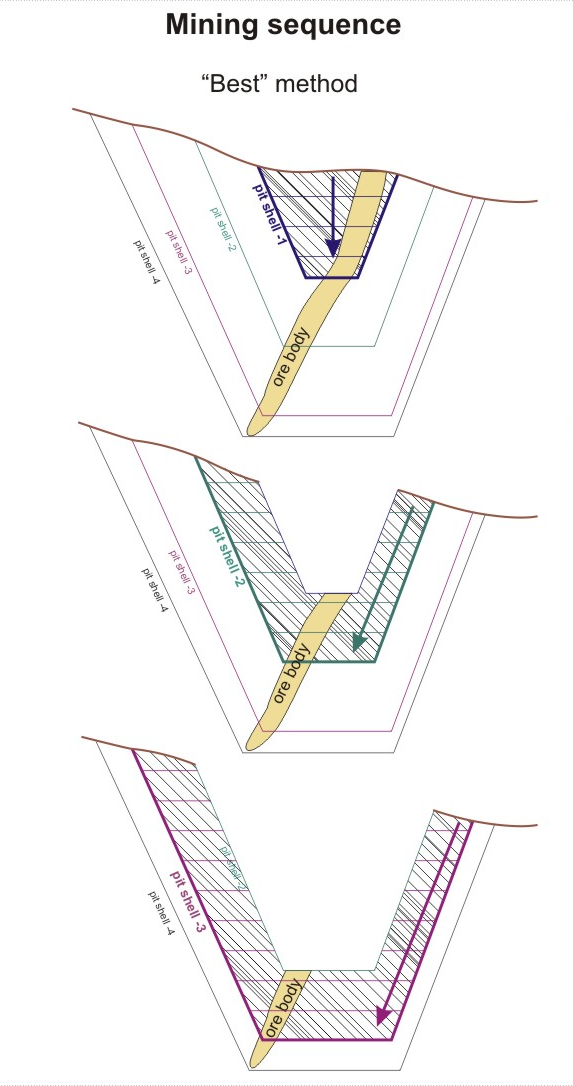

The “best” method assumes that the pit shells will be mined consecutively (initially the first one, then the second one, etc.). ![]() Show me...

Show me...

Worst case

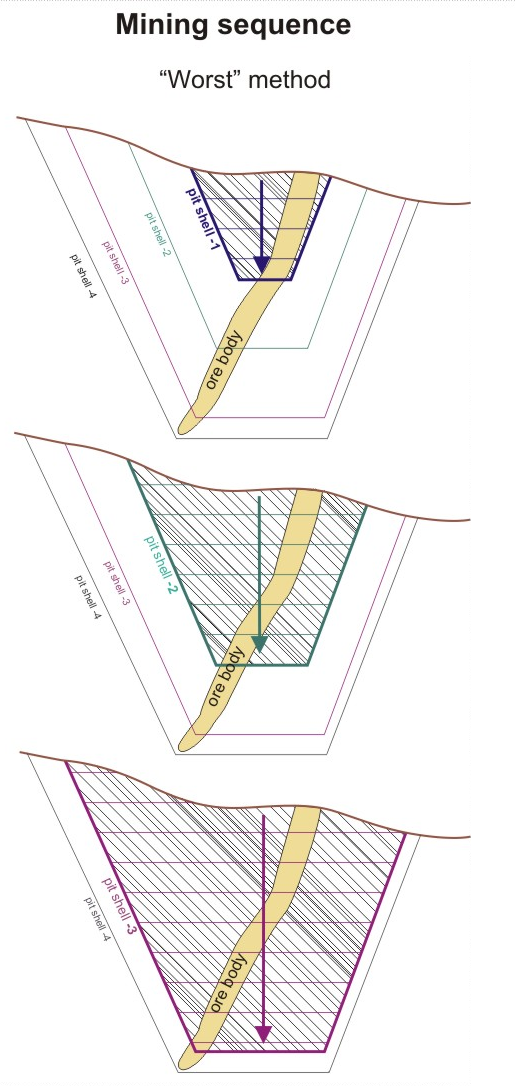

The “worst” method assumes that each pit shell will be mined completely from top to bottom, without taking any other pit shells into consideration. ![]() Show me...

Show me...

In real life, neither the "best" or the "worst" method is used on its own and the true optimal discounted pit is selected as the average between:

- the pit with the maximum NPV using the “best” method

- the pit with the maximum NPV using the “worst” method

Alternatively,

- the pit with the maximum NPV can be identified using a "Constant lag" (real life) method:

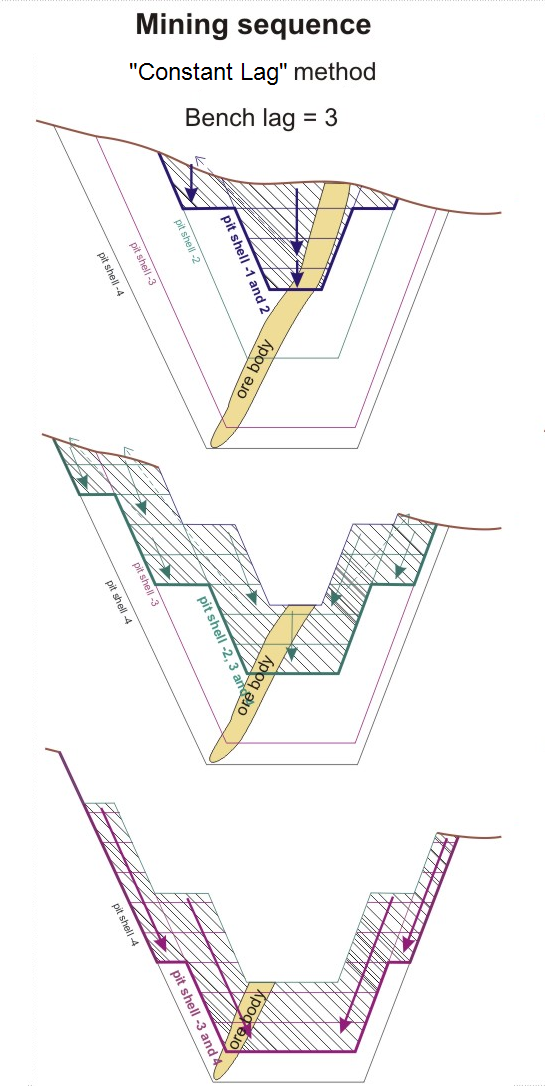

Constant lag

It is often difficult to select a pit shell with the highest achievable NPV (the optimal pit shell), when the difference between the NPV curves for the "Best" and "Worst" methods is significant. It is now possible to use a specific method to model a more realistic mining sequence and its cash flows.

"Constant lag" assumes that the pushbacks will be mined in consecutive order, as per the "Best" case scenario, but also considers the number of benches that need to be mined on each pit shell.

If the lag is set to 0 (zero), each push-back is completed before the next is started, so the analysis works exactly like the "worst" case. Obviously, increasing the bench lag takes the mining sequence closer to the "best" case.

If the lag is 3, then bench (n-3) of the second pit shell will be mined at the same time as bench (n) of the first pit shell. In other words, the second pit shell is not mined until the third benches of the first pit shell are mined out, and the third pit shell will only be mined when the third benches of the second pit shell have been mined out completely.

The Pit Optimisation process will now report the MIN-MAX ranges of the benches (which are the Upper and Lower benches in each pushback). Because the "Constant lag" method can be used for preliminary scheduling, it is necessary to flag the block model cells by the period they will be mined and the pre-pushback to which each block belongs.

An illustration of the "Constant lag" method is ![]() shown in the following diagram...

shown in the following diagram...