General

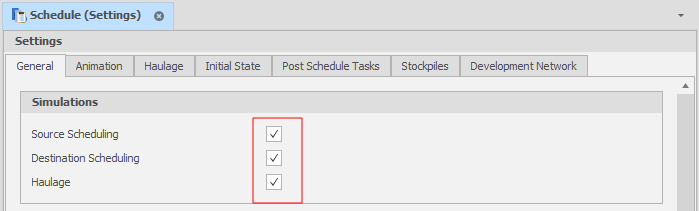

Simulations

By default, a new Scenario includes all three simulations (Source Scheduling, Destination Scheduling and Haulage). Start by deselecting the simulations you don't want to run.

The Simulation that are selected will determine which tabs are available at the top of the Settings window.

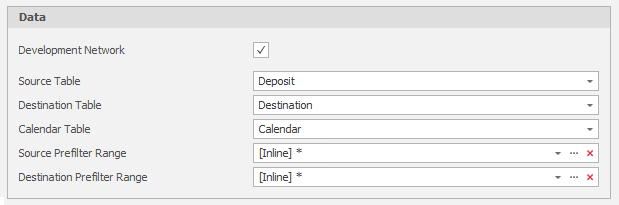

Data

Relevant Tables can be set here. Note that the Calendar Table is optional.

Development Network

Select this check box to enable the tables used to store reserving data for underground development networks.

Source Table

When Source Scheduling simulation is enabled, you'll need to set your Source table, typically "Deposit".

Destination Table

When Destination Scheduling simulation is enabled, you'll need to set your Destination table (in the Data group) and your Destination Capacity field (in the Scheduling group).

Source/Destination Prefilter Ranges

These inputs allow you to set an inclusive range that limits the amount of data available to the Scenario, which is useful for large datasets where you are only working with a particular section.

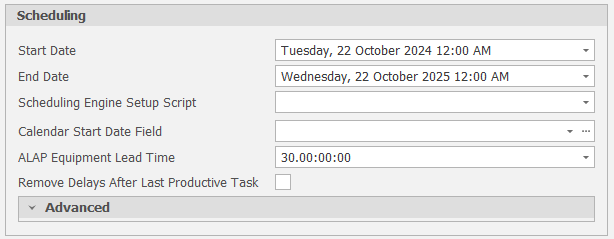

Scheduling

Start Date and End Date

Set hard limits on the duration of the simulations you want to run.

Scheduling Engine Setup Script

This optional setting can be used to control which script is executed when you run your Scenario.

Destination Capacity Field

When Destination Scheduling simulation is enabled, you'll need to set your Destination table (in the Data group) and your Destination Capacity field (in the Scheduling group).

Values in the Capacity field determine how much quantity a Destination Leaf can hold.

Destination Initial Percentage Filled Field

Anywhere from 0% (default) to 100% of each productive process can be pre-scheduled (per Leaf). Assigning an Initial Percentage Filled Field reconciles your data with any material that has already been moved to ensure you are only scheduling material that has yet to be moved.

The Initial Percentage Filled Field will only link to a Percentage Field type.

Destination Initial Centroid Field

Centroid Fields are populated using the right-click Centroid Calculator utility on a selected Solids table.

In general, floor centroids are used for Source/Deposit Centroids and roof centroids are used for Destination Centroids.

Calendar Start Date Field

If using a Calendar Table (See above), a Calendar Start Date Field must also be set.

ALAP Equipment Lead Time

ALAP solids will be depleted as late as possible in the schedule from commencement of the unlevelled date (after all ASAP tasks have been completed).

The ALAP Equipment Lead Time value controls how far equipment are allowed to start in advance of the unlevelled date. This provides “slack” in the ALAP dates, making the schedule more achievable. Without a lead time, if there is insufficient equipment to achieve the ALAP curve, ASAP tasks will be delayed.

Remove Delays After Last Productive Task

When creating a delay with a non-productive process, delay recurrences are calculated periodically based on the Start and End of Schedule. If the Remove Delays After Last Productive Task check box option is selected, the scheduling engine will ensure that delays are only added if there is a productive task that starts AFTER the start date of the non-productive process.

ALAP Equipment Lead Time (Examples)

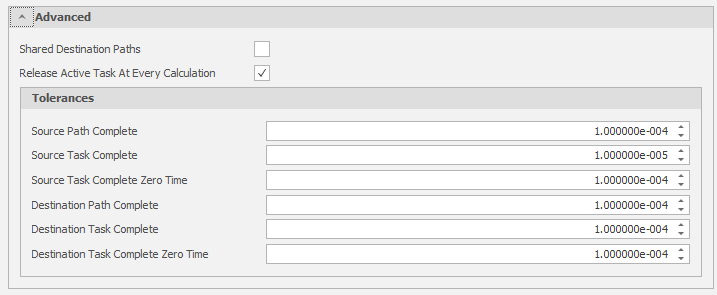

Advanced

Advanced settings allow you to enable shared destination paths and ...

Shared Destination Paths

Select this check box to allow Destination Paths to be shared between ...

Release Active Task at Every Calculation

Select this check box to release each active task when ...

Tolerances

Source/Destination Path Completion and Task Completion tolerances ensure that ...

Zero Time settings ensure that ...