ALAP Equipment Lead Time (Examples)

The ALAP Equipment Lead Time value controls how far equipment are allowed to start in advance of the unlevelled date. This provides “slack” in the ALAP dates, making the schedule more achievable. Without a lead time, if there is insufficient equipment to achieve the ALAP curve, ASAP tasks will be delayed.

For example, let's look at a few basic comparisons in a 6 task schedule (3 nodes, 2 processes) and use Gantt Charts to demonstrate the effect of setting a lead time.

There are 2 processes “process 1” and “process 2” and 3 tasks “1”, “2”, and “3”.

Dependencies are as follows:

Process order dependency: process 1 à process 2

Range Dependencies: 1 à 2, 3 à 2

Durations:

Both processes use the same source quantity at the same rate, durations are as follows:

1 - 21.7 hours

2 - 59.4 hours

3 - 87.0 hours

Sufficient vs Insufficient Equipment

Both processes only need 2 pieces of equipment per process to complete the schedule. When “Sufficient Equipment” is describing a case, it means that there are 2 pieces of equipment per levelled process, when “Insufficient Equipment” is describing a case, it means 1 piece of equipment per levelled process.

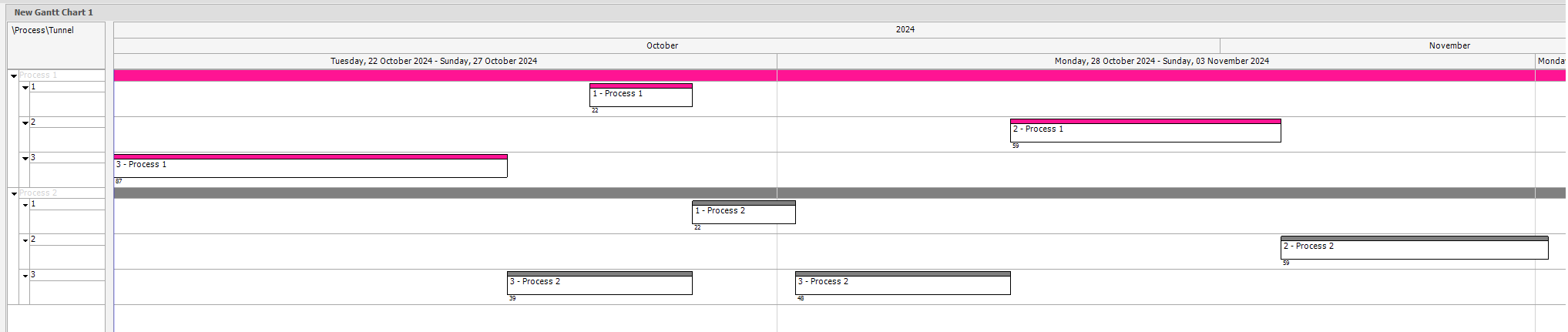

01 Unlevelled ASAP

Base Case for Comparison. Takes just under 2 weeks to run.

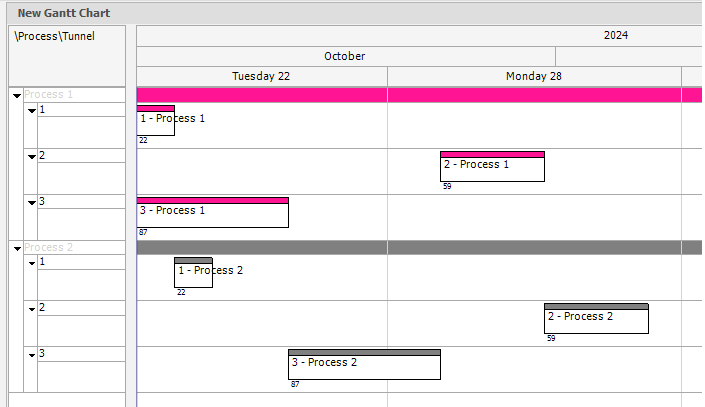

02 Unlevelled ALAP

To show existing ALAP functionality. Finishes in same amount of time as above, but tunnel 1 is delayed so that it finishes at the same time as tunnel 3

03 Partial Levelled ASAP Sufficient Equipment

Another Base case, Process 1 is unlevelled, Process 2 is levelled. Completing in just shy of 2 weeks, because there is sufficient equipment this looks the same as 01

04 Partial Levelled ALAP Sufficient Equipment

Because there is sufficient equipment, this looks the same as the 02 schedule, but it is levelled

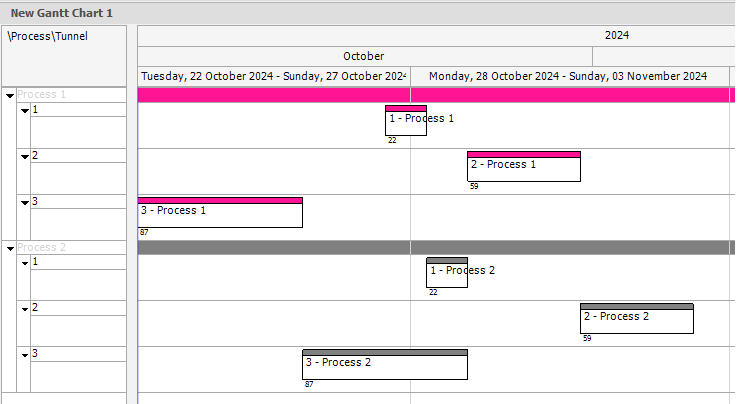

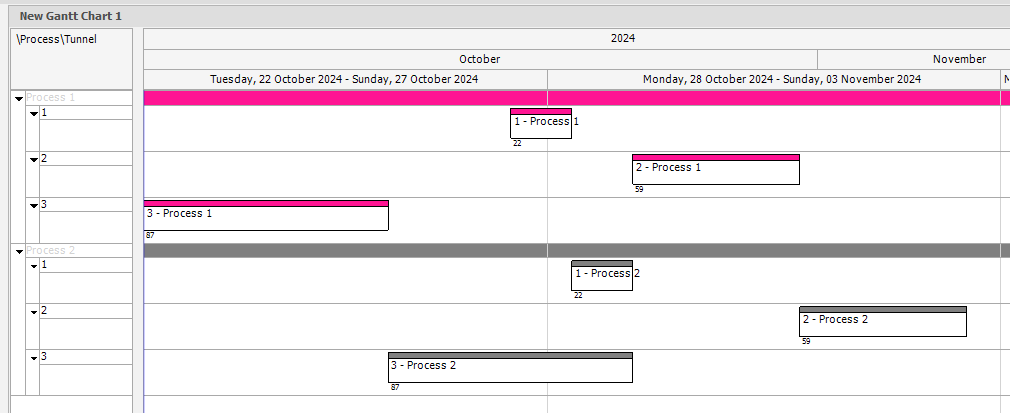

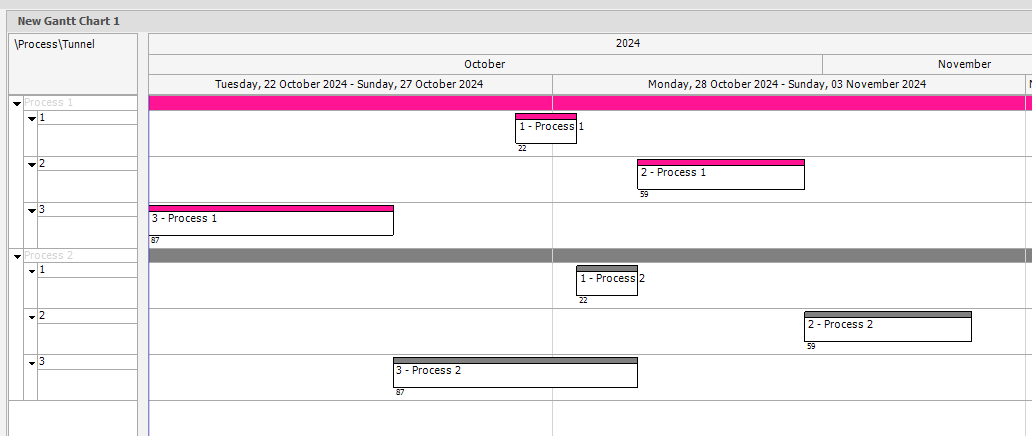

05 Partial Levelled ALAP Insufficient Equipment No Lead

In this case there is only 1 equipment, it takes slightly more than 2 weeks. If you compare to 04 you can see that the ALAP times require 2 tasks to be completed at the same time in process 2, tunnel 1 and 3. Because there is only 1 equipment working on process 2, tunnel 1 is delayed until after tunnel 3.

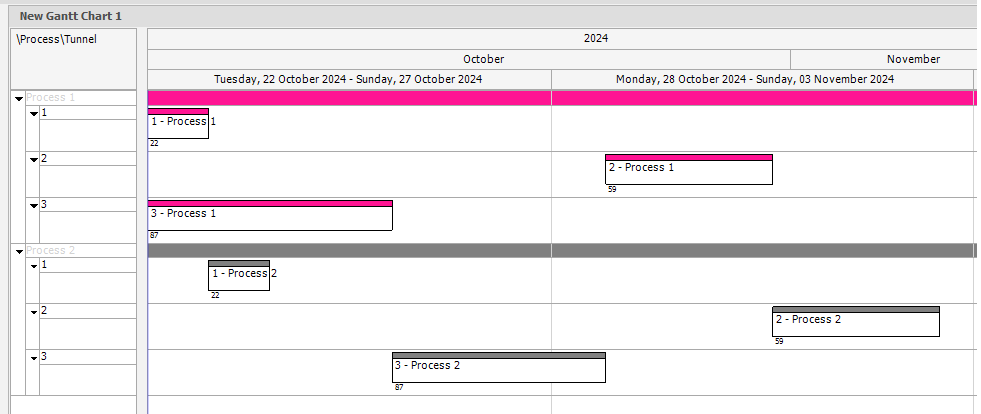

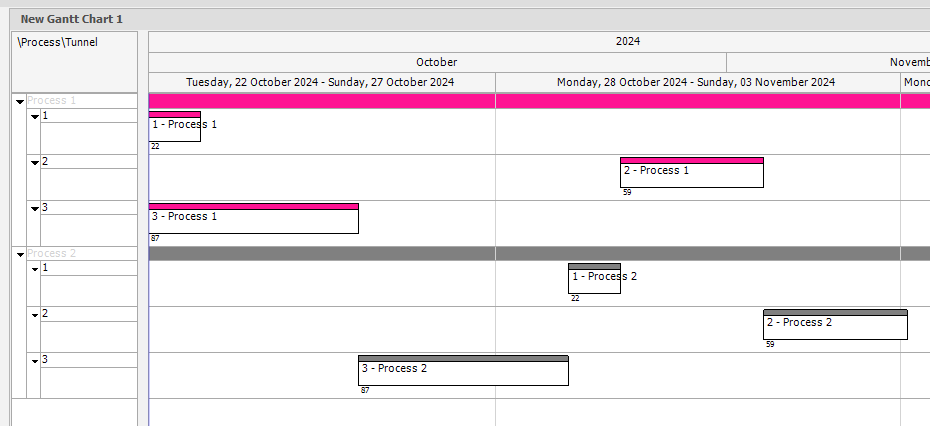

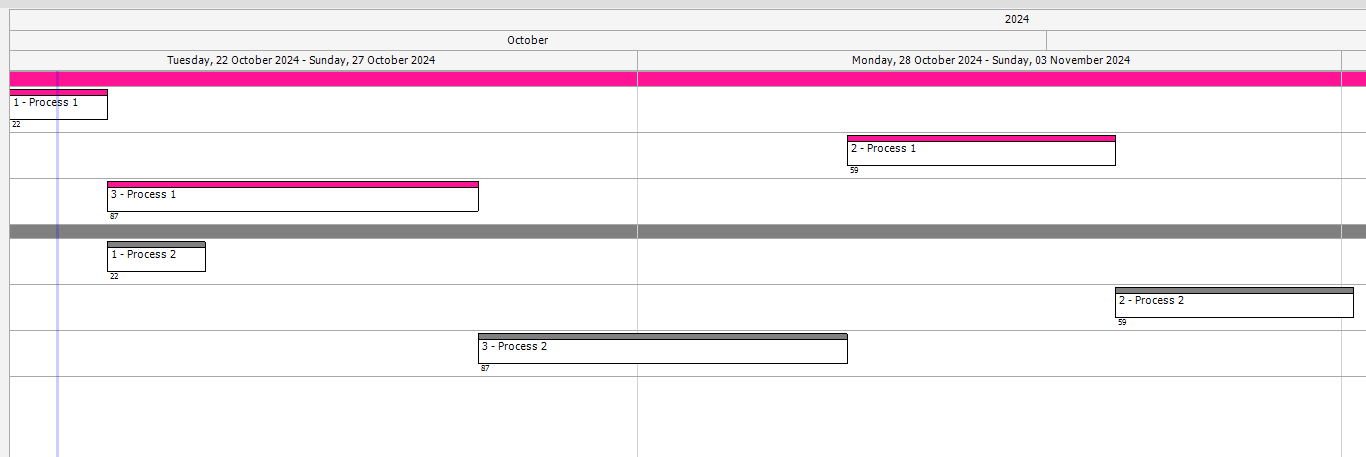

06 Partial Levelled ALAP Insufficient Equipment 4 Day Lead

In this case, a 4 day lead time is applied to 05. This allows for tunnel 1 to be executed before tunnel 3, but still later than it would have in an asap schedule (see 03). But without impacting the end date, still taking just under 2 weeks

07 Levelled ASAP Sufficient Equipment

Base case again, this has both process 1 and process 2 levelled. Once again this looks like the 01 case.

08 Levelled ALAP Sufficient Equipment

With sufficient equipment, this produces an ALAP schedule that is fully levelled that looks the same as case 02.

09 Levelled ASAP Insufficient Equipment

This is an ASAP base case with only 1 equipment per process. This is showing the situation where insufficient equipment has caused the end date to be ultimately changed. With only 1 equipment per process the ASAP case can only achieve this schedule in a little over 2 weeks.

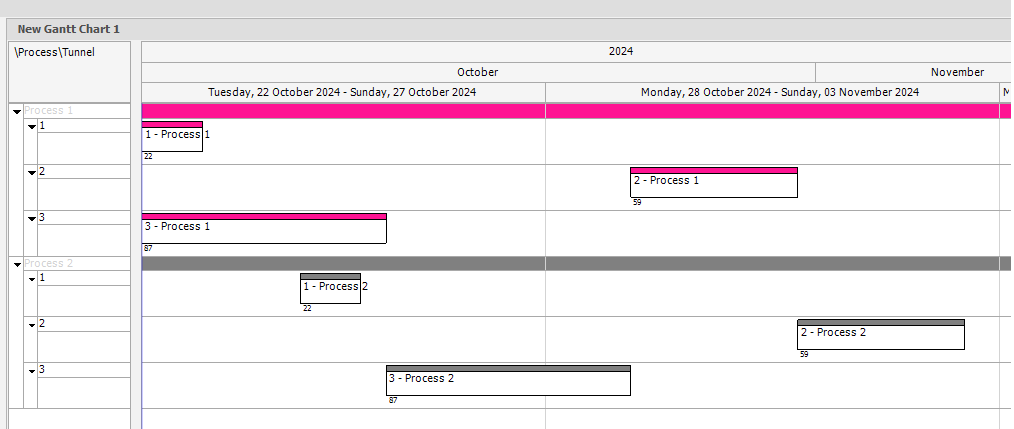

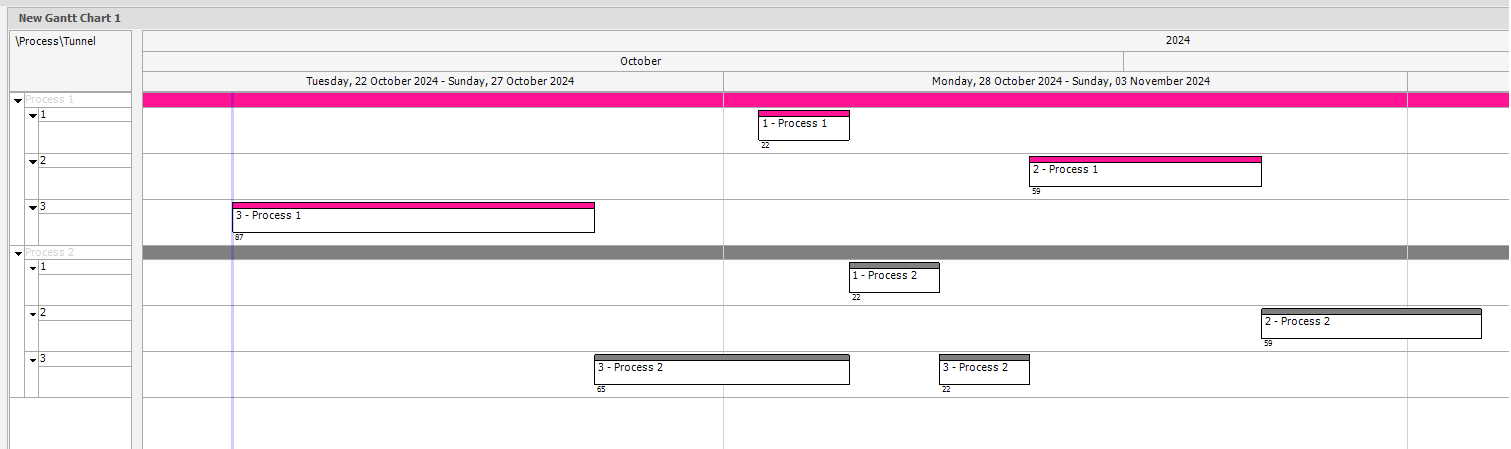

10 Levelled ALAP Insufficient Equipment No Lead

Now that we have a very unlevelled schedule with no lead time, we can see that the end date blows out by a couple of days. One thing to note here is the entire start of the schedule is delayed. This is because as per the ALAP dates it doesn’t need to do anything in those first couple of days to achieve the schedule completion specified. It pushes tunnel 1 further forward because it doesn’t need to be started yet, but that causes an equipment collision and delays everything. This is a similar story to 05.

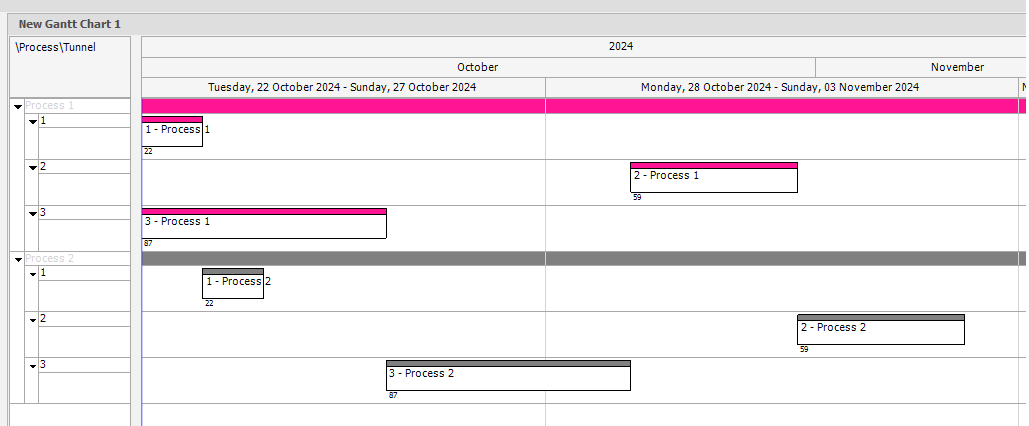

11 Levelled ALAP Insufficient Equipment 4 Day Lead

By allowing things to start 4 days earlier, we fix this issue by pulling all the tasks back, this allows the tasks to complete in the original timeframe, but delaying process 1 to start a bit later.