Step 1: Set Up Calendar Table Fields

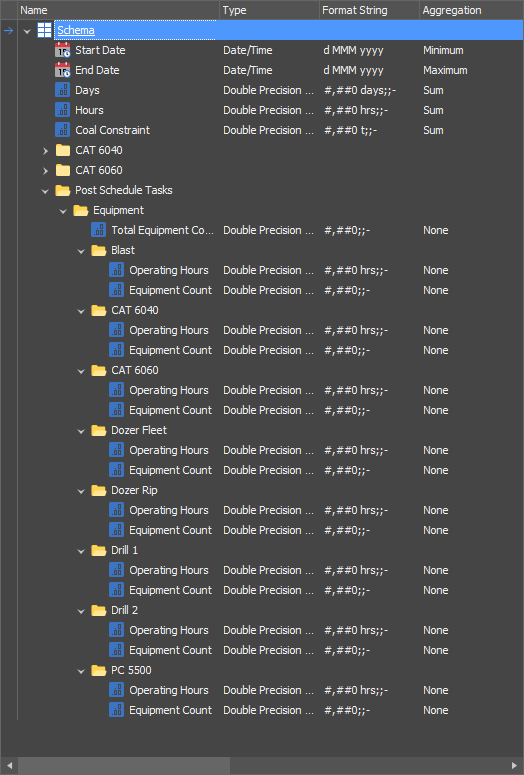

Open the Fields section of your Calendar table and create a section to store the value for each equipment.

Create two fields per equipment. The first will hold the operating hours and the second will be a calculated field to convert the operating hours to an equipment count.

Finally, create another calculated field that sums the equipment count fields.

The flexibility of this method is that each equipment has its own logic that converts from operating hours to equipment count. The logic used in this example is for demonstration purposes only.

Additional fields can be created with logic that provides a Minimum and Maximum equipment count, to provide best and worst case scenarios.

The calculated field expressions used in this example are:

"Standard Count" : Rounds to nearest integer. The denominator applies a concept of minimum operating hours per equipment.

Round(GetValue(PostScheduleTasksEquipmentCAT6040OperatingHours)/(GetValue(Hours) * 0.65),0)

"Minimum Count" : Extends the first formula by adding an equipment if any operating hours are present. Rounds down.

If(GetValue(PostScheduleTasksEquipmentCAT6040OperatingHours) > 0, Max(1, Floor(GetValue(PostScheduleTasksEquipmentCAT6040OperatingHours) / (0.65 * GetValue(Hours)))),0)

"Maximum Count": Extends the first formula by adding an equipment if any operating hours are present. Rounds up.

If(GetValue(PostScheduleTasksEquipmentCAT6040OperatingHours) > 0, Max(1, Ceiling(GetValue(PostScheduleTasksEquipmentCAT6040OperatingHours) / (0.65 * GetValue(Hours)))),0)

Lastly, ensure that the fields you created to sum the individual equipment counts have the correct calculated field expression.