Route Management

The Route Management system keeps track of all the routes and hauling movements on site. The Dispatch system calculates how long it takes a unit of equipment (typically a truck) to travel between a source and a destination, taking into account the model of the equipment and its status (for example, Loaded or Unloaded).

Only uninterrupted travel is taken into account. Movements for which an equipment unit has any down time or delay time are not included in the computation. For the Dispatch system to function effectively, it is important to record realistic and authentic travel times.

For trucks, once the haul times, the load times, and the estimated times of arrival are calculated, they are displayed on the Loader and Trucks Panel and the Truck Trips Panel in Data Acquisition.

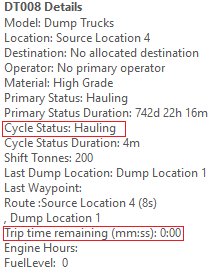

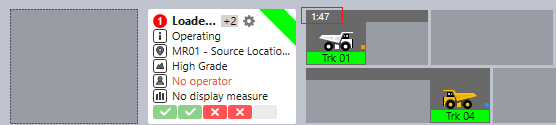

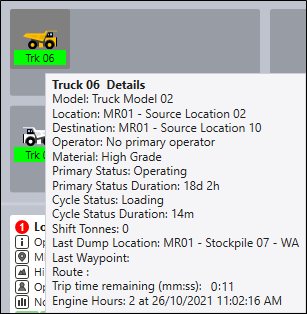

On the Loaders and Trucks panel, for example, when you hover the mouse over a truck, the details of that unit are displayed:

If an Automated data capture system is installed on-site, the estimated time of arrival of a truck is also displayed on the screen of the mobile device in the cab of the loader.

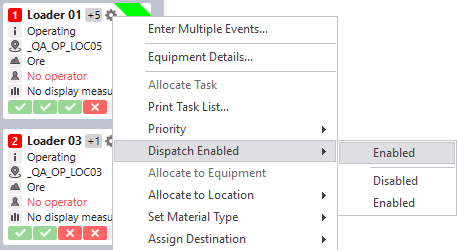

For a loader to be included in any dispatch decisions made by the Dispatch system, it must be Dispatch Enabled. This can be set in either:

- The Equipment tab of the Display pane.

- A panel, such as a Loaders and Trucks panel or a Location Activity panel.

To enable a loader for the Dispatch system:

- Right-click on the loader name and select the Dispatch Enabled option.

A half-cog icon is displayed above the loader name: this indicates that dispatch is enabled for the loader.

A route includes a source and a destination, and can be split into sections by defining waypoints. A waypoint is an intermediate location along a truck route. Waypoints are defined in Reference Edit.

The Route Management system stores the time taken to travel between each segment of the route and adds these together to determine the entire route time. The advantage of this approach is that a truck may be part way through a route. Using the last known waypoint, a more accurate estimated time of arrival can be determined.

Routes are keyed by truck model, since the time taken to travel a route will differ depending on the truck model. The load state of the truck is also considered when determining the route time.

Routes can be static or dynamic. Static routes are configured in Reference Edit. See: Defining a route. Dynamic routes are created as they are travelled. The times defined between waypoints in static routes can either be fixed or inferred. If fixed, then the defined value will always be used and never updated. If inferred, then the defined value will only be used when a more up-to-date duration does not exist.

Fixed values can only be changed by editing the reference data. The times between waypoints in dynamic routes will automatically update as routes are used. Even if a waypoint pair is defined as fixed, the dynamic routes will be captured and stored in the knowledge base. However, these are not used when working out route times.

When determining which route a truck should take, the system will determine the route with the shortest total time between the source and the destination. Routes which are marked as closed will not be considered. If a route is marked as locked for a source-destination combination, then it will be used over all others.

If no route can be determined between a defined source and destination for a truck model and load state, then in order to arrive at an approximation of the route duration, the following will occur:

- Find a route with the same load state, but with the source and destination reversed.

- Find a route with the opposite load state, but with the requested source and destination.

- Find a route with the opposite load state and with the source and destination reversed.

- If one end of the route is a primary location, then find the previous location of the loader and lookup the route to/from this location.

- Double the average route time to other locations in the same mine area.

- If one end of the route is a primary location, then substitute this with the mine area attribute and lookup the route to/from the mine area.

Data Acquisition

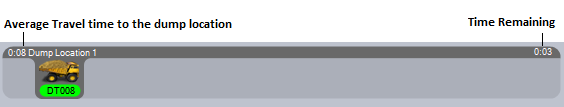

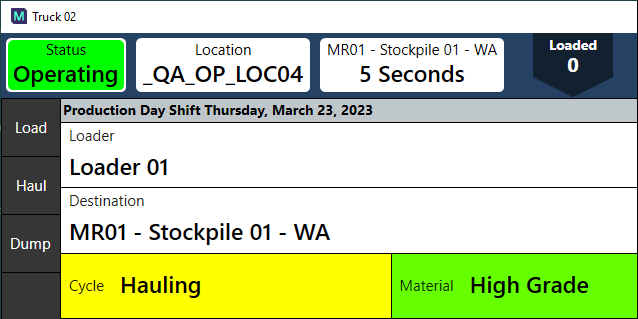

Once route information has been collated in the knowledge base, Pitram can make use of this information and calculate ETAs, haulage times and load times etc. In the Data Acquisition screen, estimated completion times are shown in the top-right hand corner of each tile, for each stage in the truck cycle:

In the example above, for example, we have 11 seconds of load time left for a truck.

You can hover the mouse over any truck and see the ETA displayed as part of the properties of that truck.

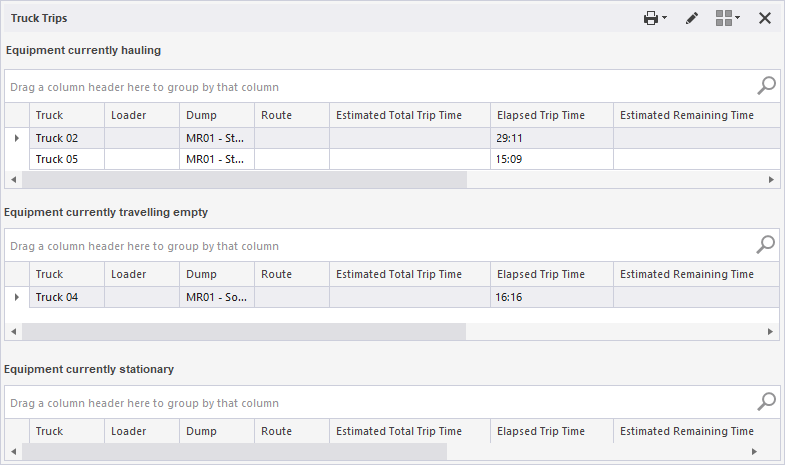

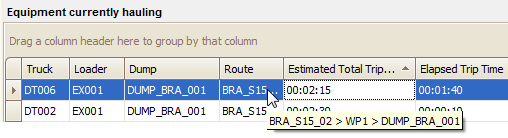

The ETA and other trip information are also shown in the Truck Trip panel:

In the Truck Trip panel, you can see which trucks are currently hauling to which loaders, the routes they are taking, the estimated total trip time and the elapsed trip time.

When you hover the mouse over a route, the start location and the destination are shown, together with any waypoints:

Mobile

The ETA is also displayed on the mobile screen of a truck. In the following screen we can see that the Truck 02 will arrive at the Stockpile destination in 5 seconds:

Similarly, the ETA of a truck is shown on the mobile screen of the loader it is assigned to. Because the loader operator knows when the next truck will be arriving, he or she can perform a clean up prior to its arrival (if time allows).

Route Management is one of the key inputs into the Dispatch System, since it allows the ETA of trucks to be calculated. Those ETAs can then be factored into the planning process in order to minimise truck queuing and loader wait times.