Whittle Proteus

![]()

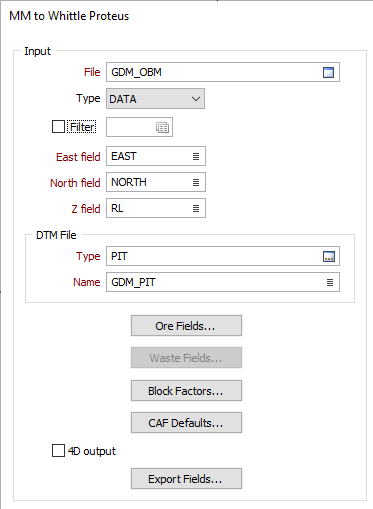

All necessary information, including 3D block model and DTM parameters, must be supplied in the MM to Whittle Proteus form.

In addition to information on block GRADE, ROCK TYPE, Density MCAF and PCAF’s, the interface allows you to specify Density, MCAF and PCAF’s for waste blocks. Block factors can be used to describe the portions of a block that are ore, waste, internal air, or in another ore domain.

Previous Whittle interfaces provided by the application allowed for the alteration of Density, MCAF and PCAF with depth. Using the MM to Whittle Proteus interface, the depth at which the new default values take effect can be variable and can be controlled by DTMs. The pit profile index allows information on the pit profiles (slope angles) to be defined in the block model file.

The Ore parcels facility allows multiple ore parcels to be written to the Whittle model file. The blocks in the Micromine block model file that are combined together into one Whittle block are preserved as ore parcels.

Model Parameters

In addition to the polygonal model, section block model, and sec file that defines the topography, you need the following to use this function:

- Default values for Density, Ore factor and Rock factor. The default values do not include values for ore and processing factors with the default Density as the default Ore and Mining factors are considered to be 1. This is the factor used for a typical block. Different default values for Density, together with Ore and Mining factors, can be defined to apply below selected Z values. Of the Ore or Rock factor fields are left blank then a value of 1 will be set for this factor.

- The mining block size - the smallest size that can be differentiated during extraction.

- Expected pit limits.

These parameters are optional:

- Information on the mining cost and additional processing cost per tonne of rock. Since the Whittle optimisation software generates multiple pit shells each of which are optimal under different mining and economic scenarios, the costs are presented as ratio values relative to a typical block, rather than direct dollar values. The Whittle Proteus software allows you to define the values that will be used by the reference mining block.

- Information on the type of Rock (ore) in each mining block. This must be a character string of 4 or less characters. Do not use the identifier Ore as this is used as the default Ore type.

The time taken by the Whittle software to create the model file, depends on the number of blocks. A large number can require several hours processing. For this reason, the block model blocks should be re-blocked to at least a minimum mining block; early runs should be done on multiples of a minimum mining block.

Block Model file

Double-click (or click on the Select icon) to select the name of the block model file and the names of the coordinate fields in that file.

X, Y and Z fields

Specify the names of the fields in which Easting and Northing and Z coordinates are stored in the input file.

DTM file

Double-click (or click on the Select icon) to select the type and name of the DTM file that defines the topography. Note that the input block model should have air blocks (blocks above the specified DTM surface).

Ore Fields

Enter the names of the Ore fields in the input block model file.

Waste Fields

Enter the names of the Waste fields in the input block model file.

Block Factors

Click this button to open the dialog box where you can enter block factors. Block factors carry information on the proportion of a block which is defined as Ore, Waste, Internal air, or is referenced elsewhere in the block model (Domain).

CAF defaults

Enter values in the CAF Defaults form. These will be used if you don't have fields in the block model file containing Density, PCAF and MCAF values for ore and waste or if values are missing in these fields. You can also enter further default values for blocks beneath given Z values or DTMs.

4D output

Select this option when you want to limit the output to one grade field.

Export Fields

Click the Export fields button to specify which grade fields will be exported to the model parameter file.

Profile Index field

Enter the name of the field in the block model file that contains the profile indices that will be used by the Whittle 4X application. For more information, refer to the Profiles topic.

Default value

Enter a default value for the pit profile index. This will be substituted when there are values missing from the profile index field.

Use parcels

Define whether of not you want to write ore parcels into the blocks in the Whittle model file. Ore parcels are used to preserve information, which could affect the economics of a block when the Whittle block is composed of multiple blocks. Once the Parcels option is checked you can then define the way in which blocks will be combined to form a Whittle block.

Optimising volume

The optimising volume defines the total volume for which optimising will be performed. Enter the coordinates at the lower corner of the volume in Min E, N and Z and the coordinates in the upper corner of the volume in Max E, N and Z.

This volume will generally be larger than the volume of the Block model. The reason for this is that the model normally consists of ore only and it is necessary to allow for the pit slopes within the Optimising volume.

As a rule of thumb the extra space you allow on all sides of the block model should be equal to the depth of the block model. For example, if you had a MM block model with the following dimensions East 1500 – 1700, North 2300 – 2600, Z 300 – 550 make the optimising volume East 14750 – 17250, North 22750 – 26250, Z 300 – 500.

Output model format

Select the format for the Output model file. COMMA DELIMITED requires less disk space.

Output model (*.mod) and parameter (*.par) files

(Optional) Enter the names of the output model and parameter files. Note that these two output files must share the same name.

Alternatively, accept [AUTO] as the default file names. The name of the input file will be used to name the output files.

Report file

Enter a name for the Report file generated by the function. The Report file will provide a summary of the operation and/or the results returned by the operation.

Run

Finally, click Run to run the function.