Drill Scheduling

In this section you'll find all the information required to set up drill scheduling in a production model.

Introduction

Drill scheduling introduces delays relating to blasted stocks, available real estate, and fleet logistics.

Embedded in Alastri software, the drill scheduling feature is intended for sites with narrow contours and/or cutbacks, where digger scheduling must take into account the time to campaign-drill areas before mining.

Drills can be limited by both fleet numbers and by drilled stock limits, which can be used to estimate drill numbers required in medium to long term plans.

Finished plans may be published as a colour-coded drill plot for issue to 48-hour planners.

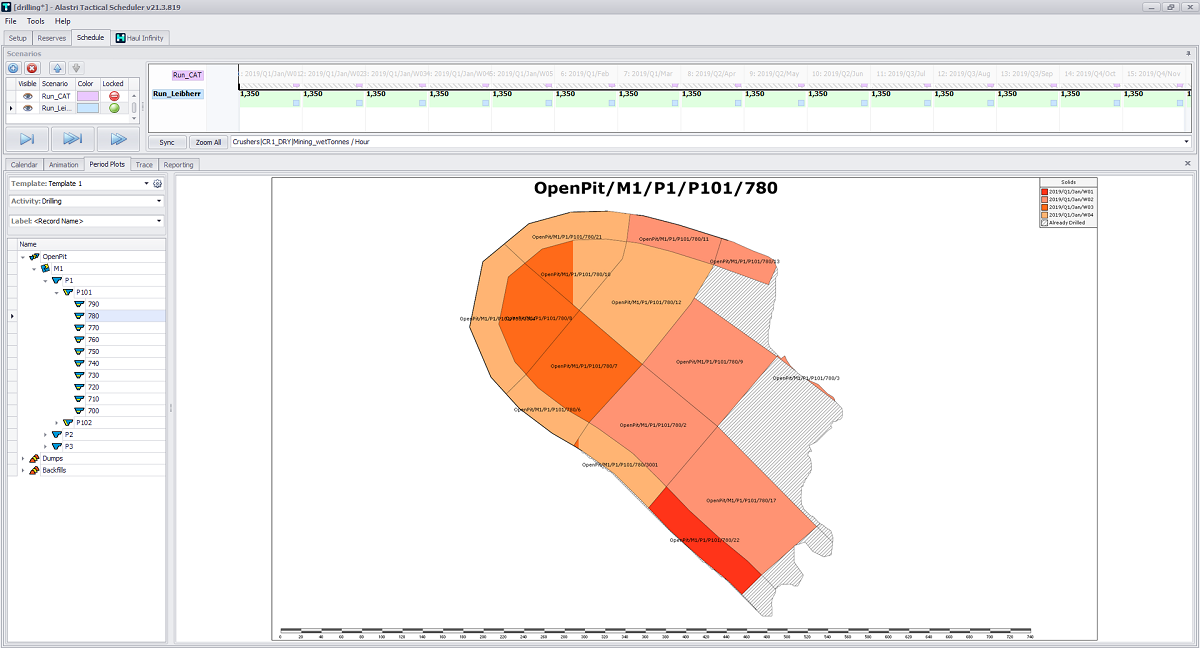

Drill Scheduling Period Plots overview

Workload

Drill scheduling requires preparing, importing and using data in addition to the existing production schedule workload.

Rapid Reserver

-

Enter block properties such as Shot Type, Block Type, Hardness, Blast Status.

Tactical Scheduler

-

Enter drill meters remaining in half-drilled shots.

-

Enter number of drills operating in a pit, stage or bench.

-

Enter manual drill sequences at the bench level (if required).

Setup Procedure

Step by step guide to set up drill scheduling in a production model.

Rapid Reserver Setup

In Rapid Reserver, add the blast properties which will affect drilling.

-

Block Type: Contour, Ramp, Trim, Production.

-

Shot Type: Presplit, Wall Control, Production.

-

Rock Type: Hard, Medium, Soft.

-

Blast Status: Not Drilled, Drilled, Blasted.

Choose blast properties that are appropriate for your site.

Tactical Scheduler Setup

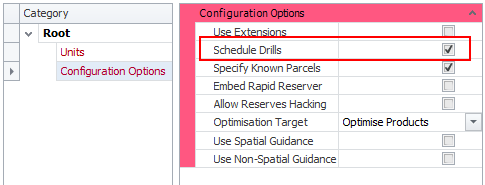

Configuration Options

To allow Drill Scheduling, select the Schedule Drills check box in the Settings > Configuration Options setup step:

Schedule Drills flag in the Settings > Configuration Options setup step

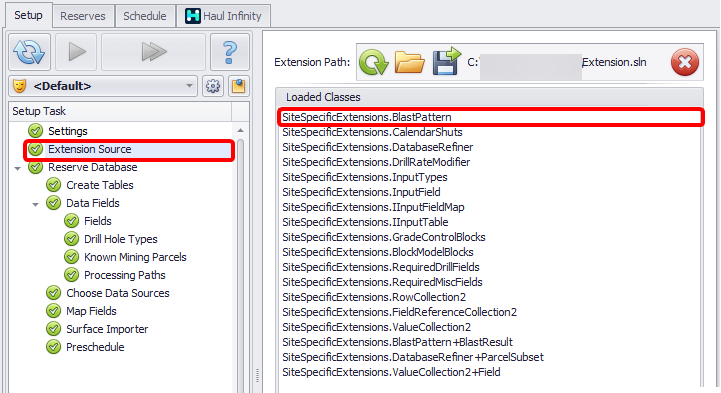

Extension Source

In the Setup Task > Extension Source step, select the Site Specific Extension that has been provided by Alastri. The extensions hold the logic for populating block-by-block drill quantities from user inputs.

Select the site-specific extension in the Extension Source step

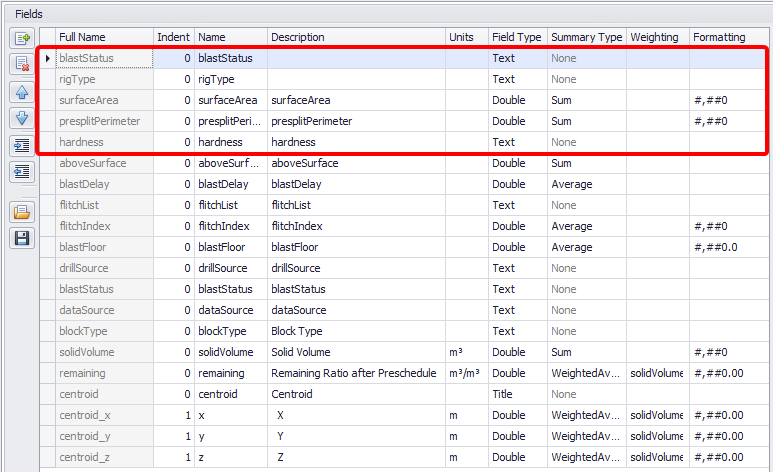

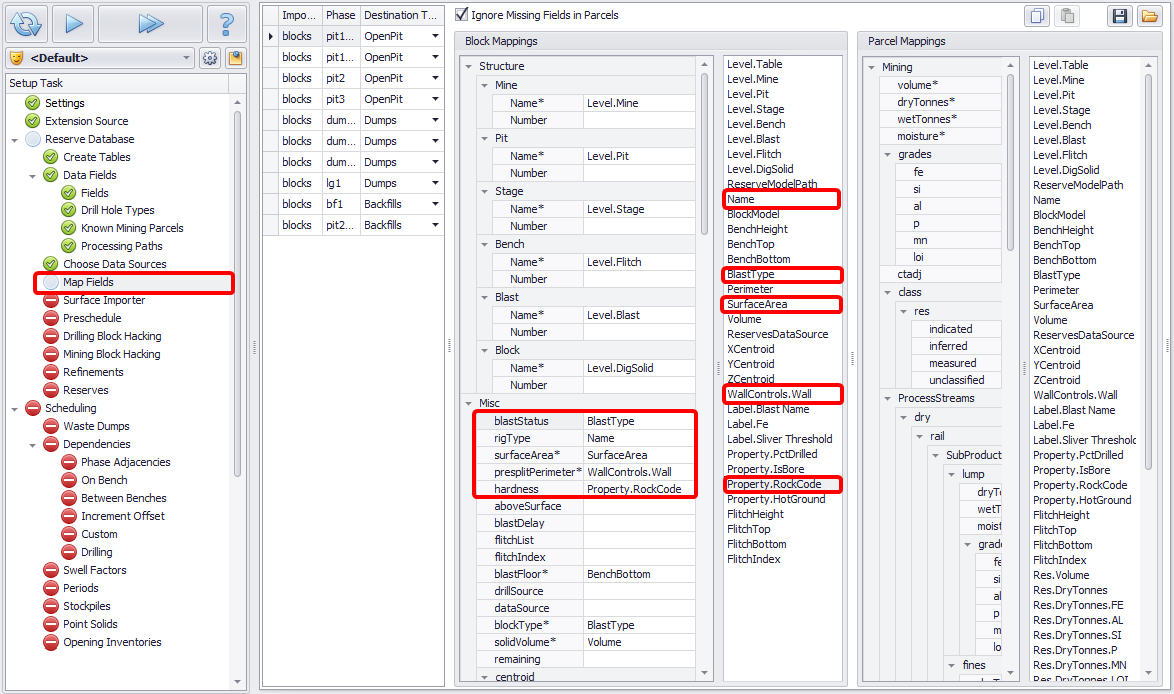

Misc Fields

In the Setup Task > Reserve Database > Data Fields > Fields step, create new Misc Fields to classify the blast blocks:

-

Surface Area

-

Presplit Perimeter

-

Blast Status

-

Hardness

-

Rig Type

Create Misc fields in the Data Fields > Fields step

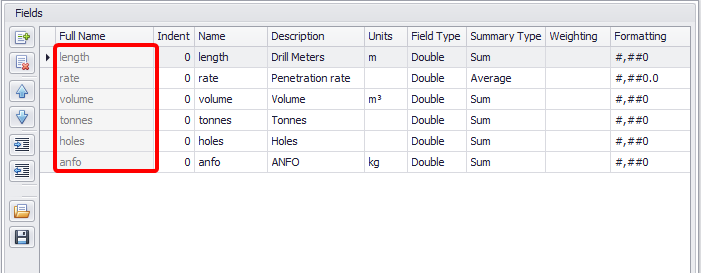

Drilling Fields

In the Setup Task > Reserve Database > Data Fields > Fields step, add Drilling Fields such as number of holes, length, volume, and so on.

Create Drill hole reporting fields in the Data Fields > Fields step

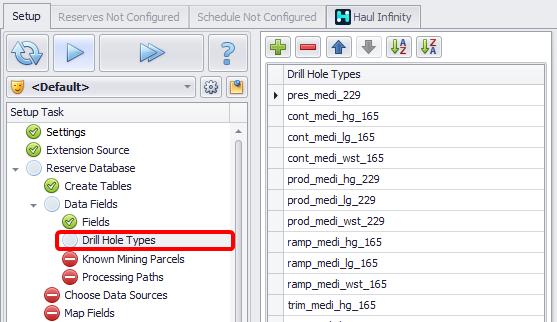

Drill Hole Types

In the Setup Task > Reserve Database > Data Fields > Drill Hole Types step, add the hole types that will be encountered in the project.

Add the hole types in the Data Fields > Drill Hole Types step

Map Fields

In the Setup Task > Reserve Database > Map Fields step, Map the reserves values into the new Misc Fields.

Reserves fields mapping into Misc fields in the Map Fields step

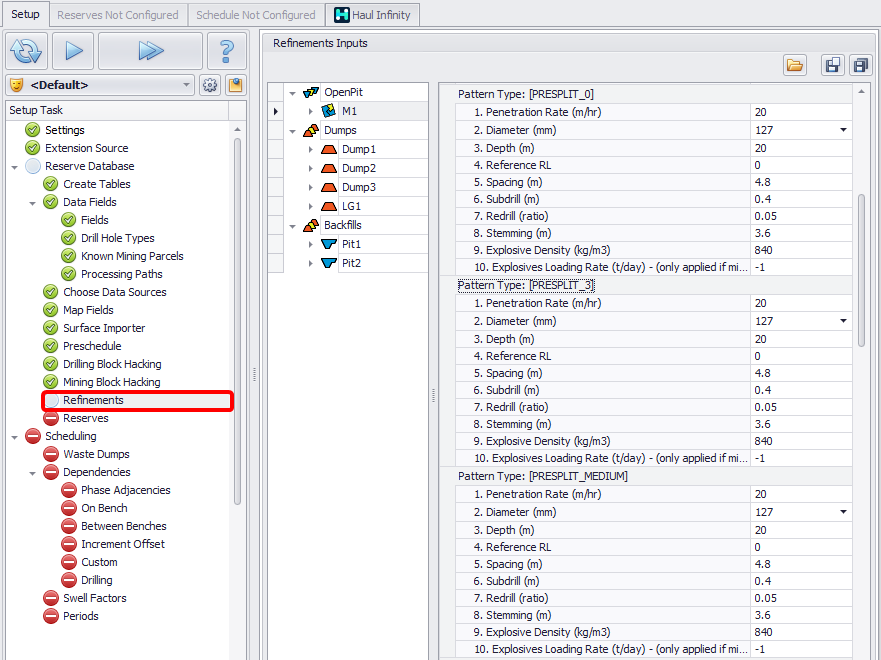

Refinements

In the Setup Task > Reserve Database > Refinements step, review parameter input tables, displayed for every hole type that is detected in the reserves, and enter the appropriate parameters for each hole type.

Parameters in the Reserve Database > Refinements step

Blast parameters and calculation methods may be configured in the Site Specific Extension.

Drilling Dependencies

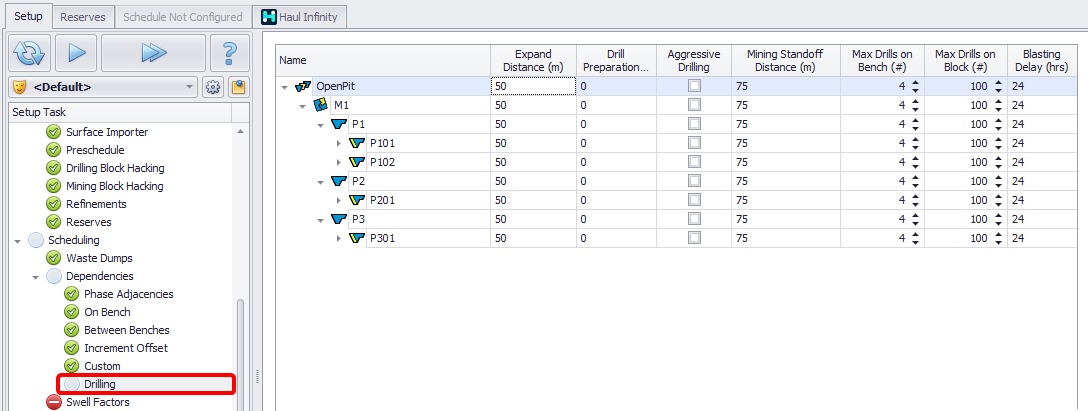

In the Setup Task > Scheduling > Dependencies > Drilling step, enter the dependencies to be used in each mine, pit, stage or bench.

-

Expand Distance: a block may only be drilled if all blocks within the Expand Distance have been mined out.

-

Drill Preparation Delay: time delay required to perform necessary preparations for drilling, if required (in hours).

-

Aggressive drilling: allows drills to begin drilling exposed dig solids, even if the whole blast is not fully mined off yet.

-

Mining Standoff Distance: minimum distance between any drill and any loader.

-

Max Drills on Bench: limit the total number of drills on the bench.

-

Max Drills on Block: limit the total number of drills on a block.

-

Blasting Delay: fixed blasting delay by bench*.

* Blasting Delay can be made a variable in the Site Specific Extension if required.

Dependencies in the Scheduling > Dependencies > Drilling setup step

Drill Types

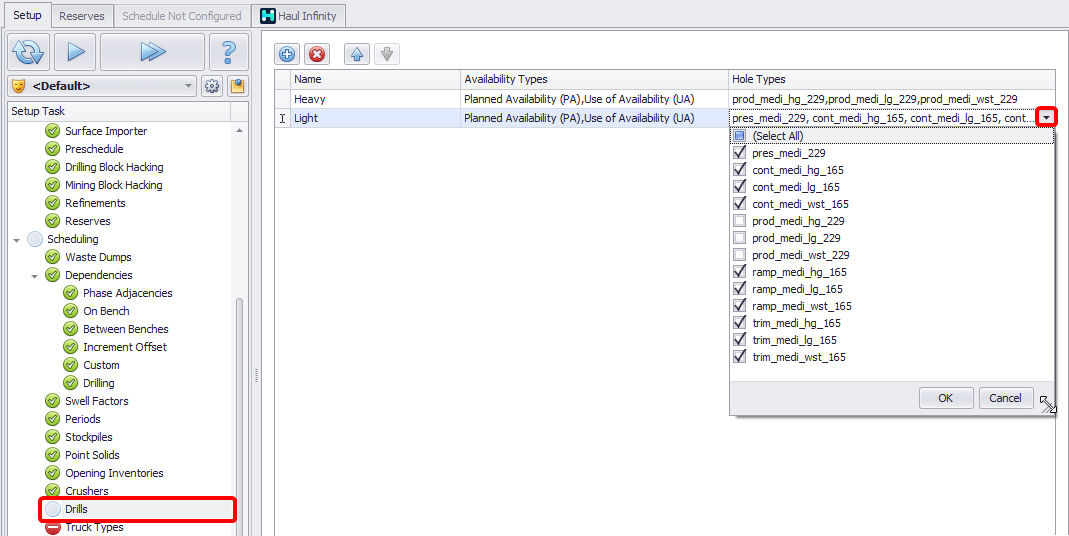

In the Setup Task > Scheduling > Drills step, add the drill rig types to be used in scheduling.

-

Tick the availability types to be added as rows in the Calendar (Schedule tab > Calendar).

-

Tick the hole types that can be drilled by each rig type.

Drill Rig > Drill Hole Types drop-down in the Drills setup step

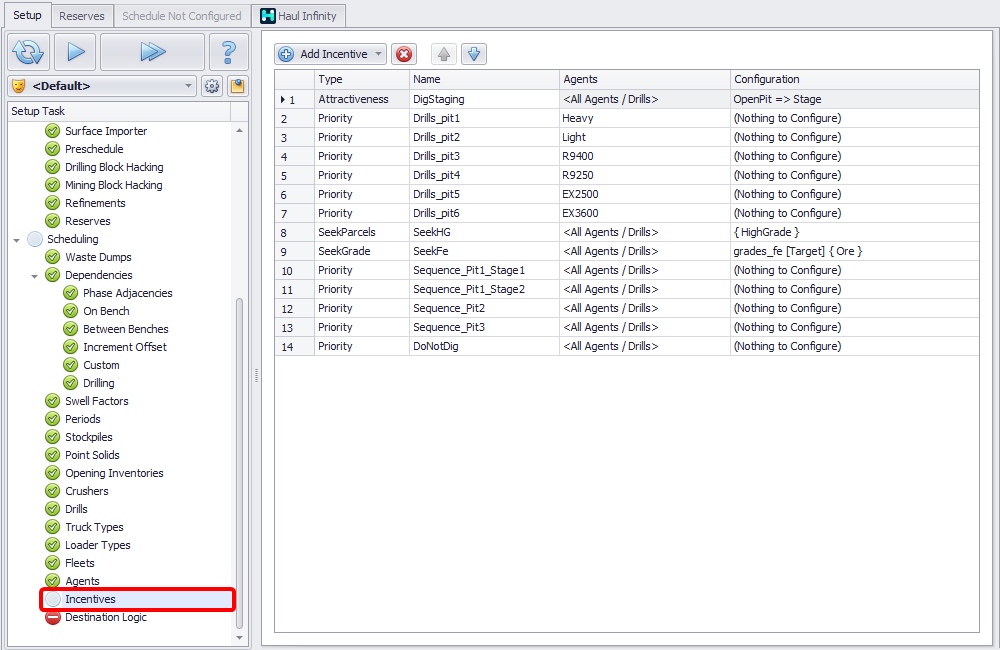

Incentives

In the Setup Task > Scheduling > Incentives step, add priority incentives to store the drilling sequence for each pit.

Add priority Incentives in the Scheduling > Incentives setup step

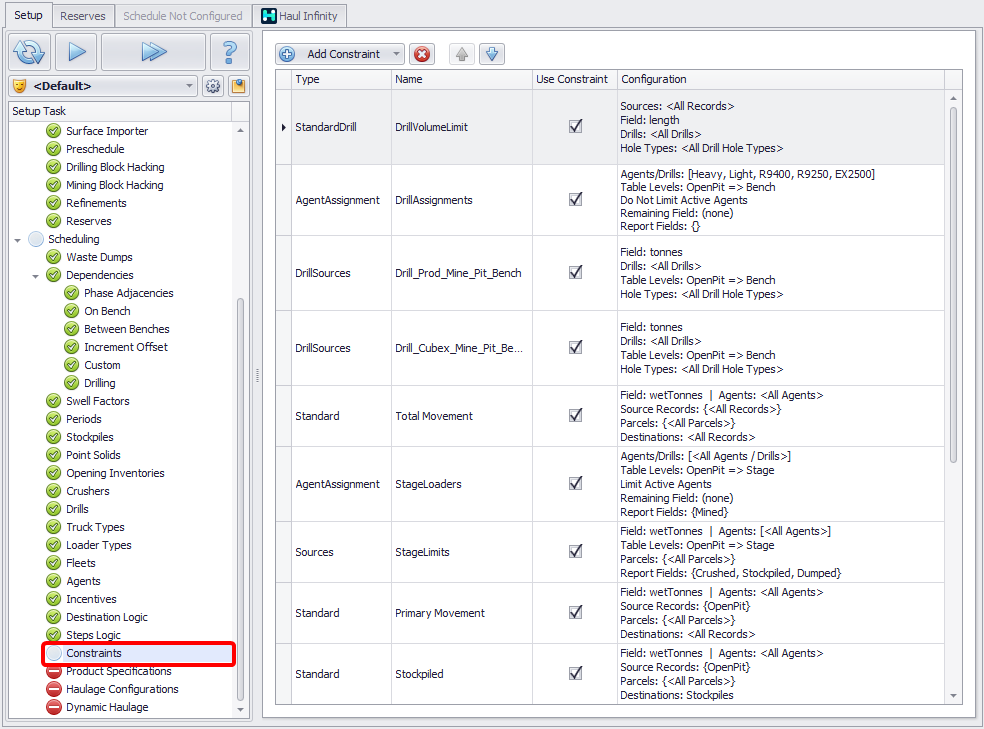

Constraints

In the Setup Task > Scheduling > Constraints step, add constraints to control blast stocks limits, drilling meters by pit or bench, and drill unit assignment by area.

-

Constrain stocks blasted in the period with a Standard Constraint on drill volume.

-

Constrain number of each drill type by pit or bench with an Agent Assignment Constraint.

-

Constrain drill quantities by pit or bench with a DrillSource Constraint.

Add constraints in the Constraints step