Drill and Blast

On the Services ribbon, click Drill and Blast to predict the quantity of dilution that may occur before and/or after blasting, and therefore better predict the quality of the material to be removed from mining locations.

![]()

For underground mining, the stoping Geologist will adjust the predicted dilution based on observations, whereas in the open pit, any ore removed from the block in excess of the design (plus predicted dilution) will be treated as dilution.

Introduction

The objective for drill and blast engineers is to create a design which will deliver a certain mass of material at a certain grade following a blast.

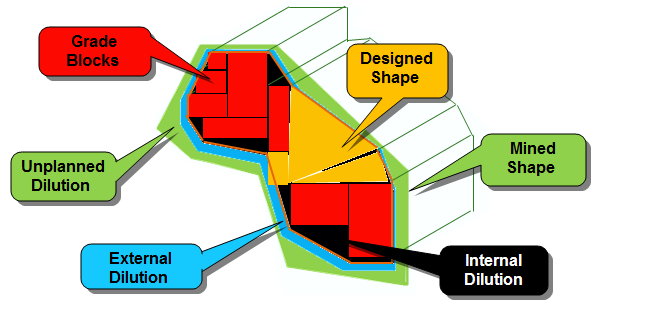

To better accommodate dilution within the design and the subsequent tracking of material, the Drill and Blast Management service can be configured to take into account different types of dilution, either before blasting occurs (in the case of open pits) or after blasting occurs (for stoping methods).

| Designed shape | The area that encloses the blocks or stopes to be mined. This includes internal dilution, i.e. the waste that is removed during the mining of the material. |

| Planned shape | The best estimate of what we think we will mine, based on historic mining performance. |

| Internal Dilution | Internal Dilution Material below the economic cut off grade within the designed shape. |

| External Dilution | Material below the economic cut off grade within the planned shape. |

| Unplanned Dilution | Material below the economic cut off grade within the mined (actual) shape. |

Data Import

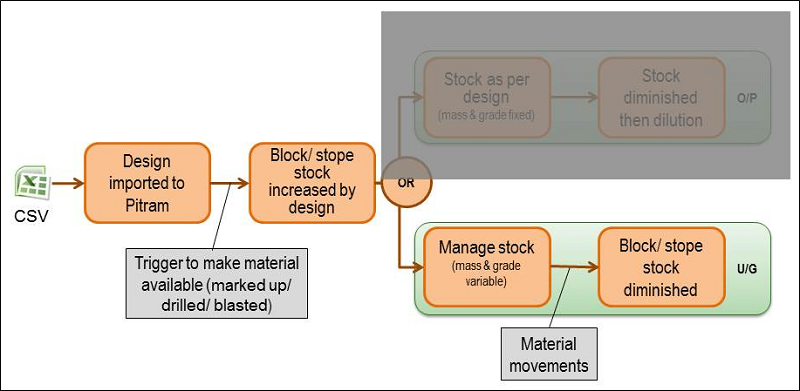

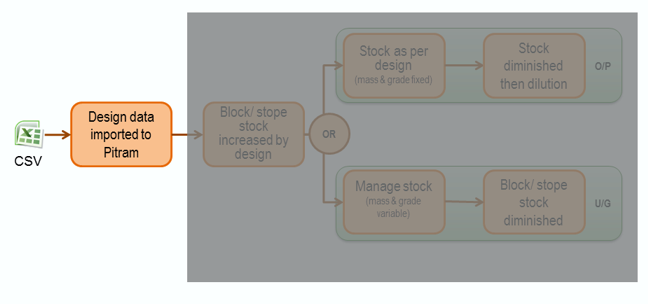

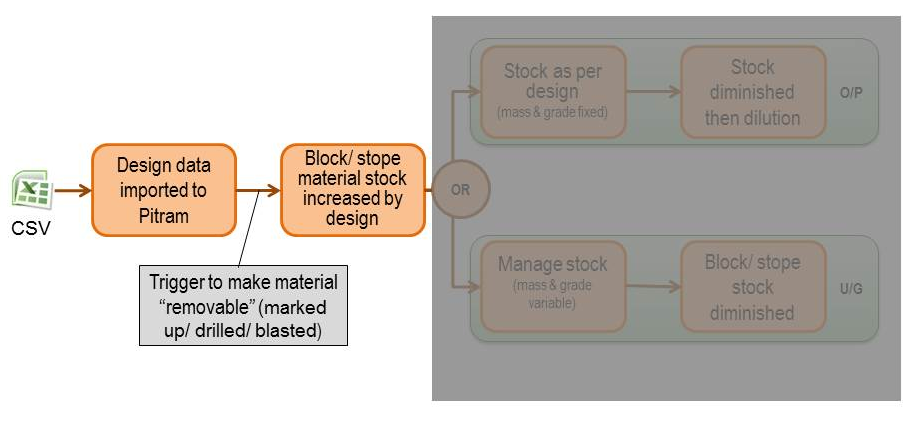

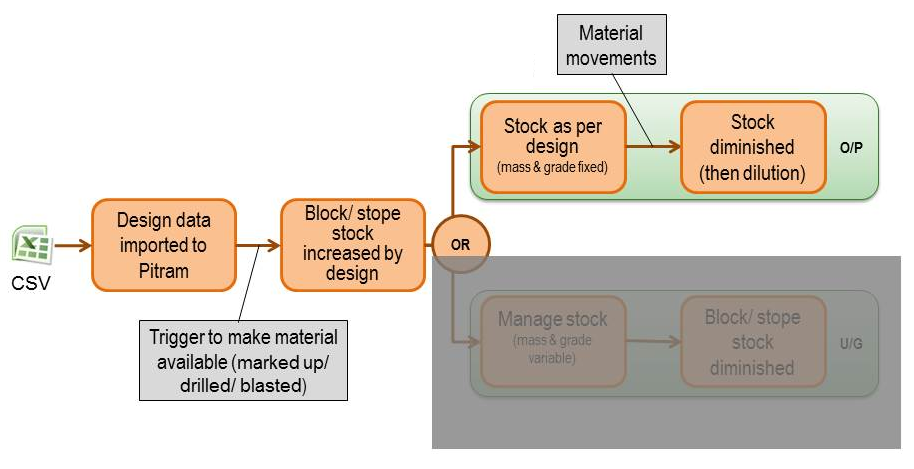

Design data is imported into the Drill and Blast service in CSV (Comma Separated Value) text format.

The import process is usually a two-stage, sometimes three-stage process :

- Firstly, the basic location data (blocks or stopes) is imported, together with optional SG, Moisture, Draw percent, and Recovery factor data values.

- Secondly, the design data is imported (the fire/shot/blast ID, design and multiple dilutions, weights and grades).

- If required, a third import stage can be included to bring in sub-location data e.g. ring data, drill lengths and totals for each ring.

Note: Individual hole data cannot be imported.

Data Design

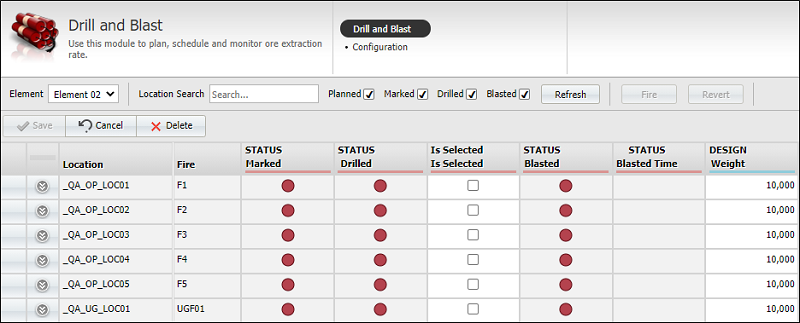

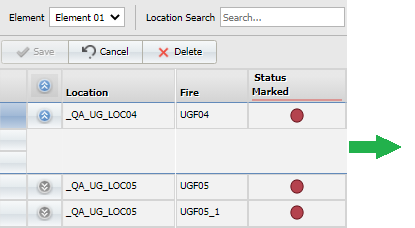

Once data is imported, the data grid in the Drill and Blast screen provides the interface between the firing process and the movement of materials. The grid displays the imported design data. Locations are shown in summary:

Depending on the Precondition business rules that have been configured, Pitram will allow the manual release of the design, including Dilution weights and grades, making it available for removal (in Pitram).

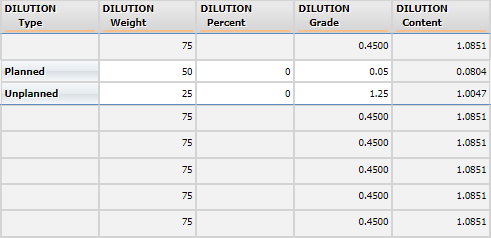

Expanding a row using the icon in the first column, shows the dilution components of the design:

|

|

Use the horizontal scrollbar at the bottom of the grid to view the dilution details.

The options in the Period section of the ribbon allow you to load drill and blast data for a specific date range, for selected shifts.

A Location search and filter check boxes on the header above the data grid allow the data to be filtered based upon a search term and/or the firing status (planned, marked, drilled, blasted).

For example, if you enter a term in the Location Search field and click Refresh, only Locations which match your search term will be displayed in the grid.

The firing status check box, when selected, will display locations with the corresponding status. This means that deselecting a check box will filter out locations with the deselected status.

There are a number of possible scenarios. The configuration will depend on the type of mine and the processes in place on-site. Holes may or may not be marked up, drilled, or even blasted:

- There may be mark up and no blasting (free dig)

- There may be mark up after blasting

- Material can be removed once the holes are blasted

Depending on the Precondition business rules that have been configured, Pitram will allow the manual release of the design (including any dilution) weights and grades, making it available for removal (in Pitram):

- If material is removed before it is released, it will result in a movement without grade and negative stock.

The “released” material can be seen in the Stock Management screen.

- If previously released material is still present when new material is added, Pitram will calculate a new balance and a weighted average grade.

Open Pit Dilution Method

For managing dilution when mining by open pit:

- Material is removed from the location (block) until it is mined out (or other reasons to stop mining).

- If more material is removed from a block than was designed, the geologist will apply a grade to the additional material.

- Pitram records the removal of material from the location (block) using Data Acquisition or via Activity Sheet Recording.

- Each material movement is allocated the block design grade.

Underground Dilution Method

For managing dilution when mining underground:

- Rings are blasted and new material becomes available for hoisting.

- Material is removed from the location:

- The geologist may adjust the remaining material weight and/or grade.