Rules

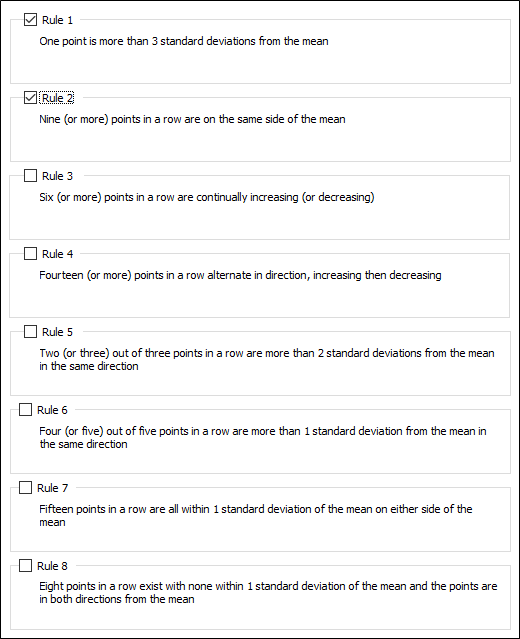

On the Rules tab of the Shewhart Control Chart form, specify the rules that will determine how out-of-control or non-random conditions are detected. In process control, Nelson rules are a method of determining if some measured variable is out of control (unpredictable versus consistent).

| Rule | Description | Problem |

|---|---|---|

| 1. | A point is more than 3 standard deviations from the mean. | A sample is out of control. |

| 2. | Nine (or more) points in a row are on the same side of the mean. | A prolonged bias exists. |

| 3. | Six (or more) points in a row are continually increasing (or decreasing). | A trend exists. |

| 4. | Fourteen (or more) points in a row alternate in direction, increasing then decreasing. | This much oscillation is beyond noise. This is directional and the position of the mean and size of the standard deviation do not affect this rule. |

| 5. | Two (or three) out of three points in a row are more than 2 standard deviations from the mean in the same direction. | There is a medium tendency for samples to be mediumly out of control. The side of the mean for the third point is unspecified. |

| 6. | Four (or five) out of five points in a row are more than 1 standard deviation from the mean in the same direction. | There is a strong tendency for samples to be slightly out of control. The side of the mean for the fifth point is unspecified. |

| 7. | Fifteen points in a row are all within 1 standard deviation of the mean on either side of the mean. | With 1 standard deviation, greater variation would be expected. |

| 8. | Eight points in a row exist with none within 1 standard deviation of the mean and the points are in both directions from the mean. | Jumping from above to below whilst missing the first standard deviation band is rarely random. |

The Nelson rules were first published in the October 1984 issue of the Journal of Quality Technology in an article by Lloyd S Nelson