Dispatch System and Reference Edit

When enabled, the dispatch system orchestrates operations on site to optimise truck and loader efficiency, while at the same time, achieving the desired production grade or blend. Some of the inputs to the dispatch system are defined in Data Acquisition: some are configured in Reference Edit.

The dispatch system takes into consideration site-defined inputs, weightings and constraints to formulate a decision.

- Inputs. These include the route travel times that are either user-defined or collated by the route management system or in Reference Edit, defined loader priorities, and a shift plan that defines the tasks to be undertaken.

- Weightings. Weightings are a way of applying a level of importance to some of the inputs. Should the current input be rigidly adhered to or could an input be overridden by a dispatch system decision? Weighting values, in most cases, range from zero (no need to comply with the current input setting) through to 1 (must comply with the current input setting). The weighting value is a measure of level of compliance that is required by the dispatch system.

- Constraints. There may be operational reasons why a particular truck needs to be locked at a particular loader. Defined dispatch regions, for example, may restrict a truck from servicing a loader in a different dispatch region.

The inputs, the weighting and the constraints applied are used to calculate a total score for the each of the loaders. The next available truck will be allocated to the loader with the highest score if the dispatch system is enabled.

About routes, waypoints and the knowledge base

The route management system keeps track of all the routes or road networks on site. This data is used to calculate how long it will take for a particular model truck to travel between a source and a destination in a loaded and in an unloaded state. Route times are recorded in a knowledge base. Any travel that incorporates a breakdown, meal break or unscheduled stop is not included in the knowledge base collection of routes.

A route can be either:

- Dynamic. These routes are those routes that are continually recorded by the knowledge base.

- Static. These are well entrenched truck routes are defined in Reference Edit. They are user-defined routes that include the travel times between a source and a destination for a particular model truck when in a loaded and an unloaded state.

A route can be split into segments by adding one or more waypoints. A waypoint is an intermediate location along a route. When a truck passes a point it is recorded as an event in the database. Using the time of the last known waypoint is an accurate way to determine the estimated time of arrival (ETA) at a destination.

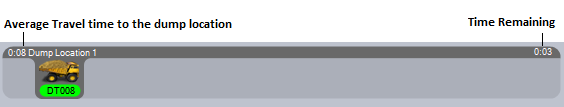

In Data Acquisition travel times are displayed on the Loaders and Trucks, and the Truck Trip panels, and on the Equipment Details summary (when you right-click on an equipment icon in a panel). On a Pitram Mobile screen a truck displays its ETA to the loader. The loader, in turn, displays the ETA of the truck. Travel times are used extensively by the dispatch system when assigning a truck to a loader.

More about routes and waypoints

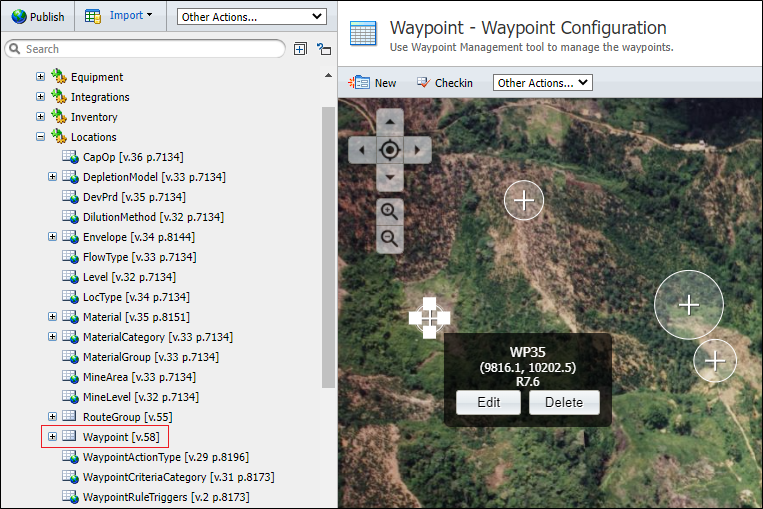

Truck routes are defined by a start point and an end point. Waypoints are either intermediate points along a route or isolated points not associated with a route. A waypoint point is defined by an east and a north, and possibly an elevation coordinate or RL. A radius defines the perimeter of influence of the waypoint.

A rule can be defined for a waypoint that specifies an action that will occur when a truck reaches the point. For example, if a truck is about to dump ore on a waste dump an alarm message is displayed on the truck's Mobile screen. Truck movements past a waypoint are recorded in the database and by the knowledge base.

The above image shows the pit, the roadworks, the truck routes and the waypoints along the routes. Click on a waypoint to show its definition: the waypoint name, the east and north coordinates and the radius.

What are waypoint rules?

A waypoint rule is a feature of a waypoint. It defines a set of criteria that, if met, will result in an action—for example, if A and B, then C. Each waypoint can have a different set of rules: some waypoints can have no rules. For example, if TruckA has a cycle status = Hauling and it passes WaypointA the rule, defined with the waypoint, sends it to DumpA. WaypointB and WaypointC may have different waypoint rules defined.

The rules are defined on the Waypoint Rules tab of the waypoint token dialog. This can be found by going to Groups | Configuration Items | Locations | Waypoint on the navigation pane in Reference Edit.

If the site is using a Mobile GPS system, and a unit of equipment enters the zone of influence of a waypoint, and if it meets the criteria defined for the waypoint, an action will be executed. For example, the following actions could be applied:

| Criteria | Action |

|---|---|

| Cycle Status: Queuing at Dump | Raise an alarm if the truck is about to dump waste on an ore dump. |

| Cycle Status: Hauling | Allocate the truck to a particular destination. |

| Equipment Model:Caterpillar 385CL | Exclusion alarm: this unit of equipment should not be in the area. |

| Primary Status: Backfilling, Bogging, Bolting | Exclusion alarm: unit of equipment with either of these states should not be in the area. |

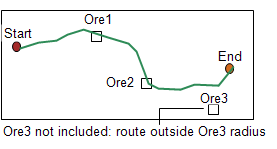

How the dispatch system determines the route

Routes and the components of a route - (i.e. the source and destination, the waypoints and the time taken to move between points) - are important components of the dispatch system. When determining which route a truck should take, the dispatch system will identify the route with the shortest total time between the source and the destination. The efficient delivery of material to the right destination is crucial to a viable operation.

A route can be defined with either of the following settings:

- Open. An alternative route may be selected.

- Locked. For a particular source-destination combination, this route should be selected by the dispatch system over all others.

If no route can be found for a particular source-destination combination for a particular truck model and in a particular load state (either loaded or unloaded), then the dispatch system will approximate the route travel time using the following strategy in the following order:

- Find a route with the same load state, but with the source-destination combination reversed.

- Find a route with the opposite load state and the requested source-destination combination.

- Find a route with the opposite load state and the source-destination combination reversed.

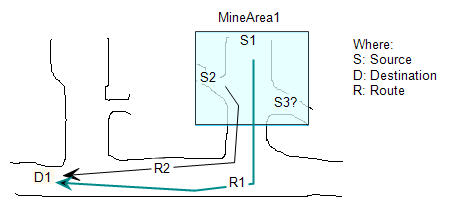

- If the truck is to travel from S3 to D1, for example, and the actual location of the source, S3, is not known, the previous travel time from the same mine area will be used. This could be S1 to D1 (R1).

- Double the average travel time to or from the same mine area. See above: R2 travel time from MineArea2 to MineArea1.

- If the truck has to travel from S3 to D1 and the actual location of S3 is unknown, take an average of all the travel times from the same mine area to D1. This would be the travel times from MineArea1 to D1 and incorporate the average of travel times for R1 and R2.

Segments of a route

A static route can be divided into segments by waypoints along the route. Each segment time can be defined as either locked or unlocked.

If the segment travel time is:

- Locked. The user-defined travel time values will always used and will not be automatically updated. Locked times need to be edited in Dome if a time change is required.

- Unlocked. The defined value will only be used if more up-to-date segment time is not available.

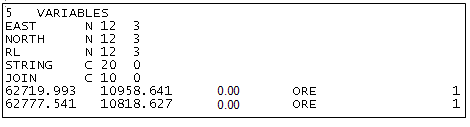

To define routes you need to have a string file in which each:

- Route can be identified as a separate string.

- Route is defined by any number of points, which may or may not pass within the radius of any defined waypoint.

- Point on each string has an identifiable east, north, an elevation or RL, join and string field. The join field is used to identify the points that belong to the same string. For example, all the points in the Ore string have a JOIN value =1 and all the points in the Mill strings have a JOIN value = 2. Any field in the file, as long as it identifies the individual strings, can be the join field.

A string file has the following format:

The string file will overlay the image file on which waypoints are defined. If a string pass through the radius of any of the waypoints, these waypoints will be include in the route. Waypoints divide the string into segments.

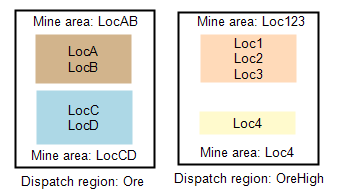

About dispatch regions

A mine site may be divided into separate geographical areas or regions. For example, the material mined in particular areas may need to be stockpiled separately; the geology on each level requires that particular capacity trucks be used, or site infrastructure automatically lends itself to separate regions. A truck servicing a loader which is located in a particular dispatch region can only travel within that region. If dispatch regions are not defined, all locations are available to a truck.

The Dispatch system takes into account the Dispatch region of a loader when allocating the next available truck.

Dispatch regions are defined in Reference Edit. They may consist of a number of mine areas; a mine area can be unique to a dispatch region or it may be included in one or more regions. If dispatch regions are not defined, trucks are not restricted by location.

For example:

In the example above:

- Dispatch region Ore = Mine area LocAB and LocCD. Trucks servicing loaders within those mine area would be restricted to those mine areas.

- Dispatch region HighOre = Mine area Loc123 and Loc4. Trucks working in the dispatch region HighOre would be restricted to these mine area.

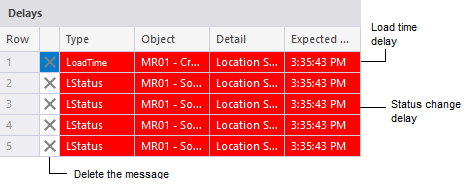

Status delay warnings

Data Acquisition has a Delays pane which lists warnings messages. The warning messages of interest are those that occur when the status of a unit of equipment or location has not changed for a defined period of time. The period of time or the threshold is defined in Reference Edit for the states to be monitored.

The Delays pane also displays two other types of warnings that relate to average loading and route times. The average time or the thresholds, in this case, are calculated by the route management system.

In Reference Edit, primary status threshold values are applied to both:

- Equipment. One of the primary equipment states that you may want monitored is the Operating status, Tramming. On site there should be no reason why Tramming should be allocated to a unit of equipment for a lengthy period. If this should occur, a warning message will be displayed on the Delays pane.

- Location. Your site may want to be informed if a location has been allocated to Cleanup for a lengthy period of time. If this does occur, a warning message will be displayed on the Data Acquisition Delays pane.

Equipment KPIs

Equipment KPIs (key performance indicators) are measurable tragets that can be used to monitor performance. They are defined in Reference Edit for equipment model types.

Any shortfalls in performance can be identified early and action initiated before production is affected.

KPIs provide no direct input to the Dispatch system. In Data Acquisition, they provide a visual indication of an equipment unit's progress towards a target.

For a unit of equipment to reach its target, both the operator and the equipment must work efficiently. An efficient loader is one that minimises load and queue times and achieves its production target with a minimum of down time or idle time. A loader, in turn, is also dependent on the efficiency of the trucks. The trucks must be ready to load as soon as the loader is ready.

Currently, four KPI types are defined in the Pitram database. They are:

- Average load time. This KPI sets an appropriate target load time for the unit. Any value below or equal to the target will achieve the target.

- Average queue time. This KPI sets an appropriate and achievable target queuing time for the unit. Any value below or equal to the target will achieve the target.

- Loader efficiency. The desirable unit efficiency rate. This is the operating time per hour presented as a percentage, which is the percentage operating time minus any time that the loader was not working with a truck.

For example, if a loader was operating for 100% of the shift and no trucks were queuing or loading at the loader for 20% of the shift, the loader efficiency would be 80%.

- Production rate. The optimum production rate. This is the amount of material loaded per hour by the unit. Any value equal to or greater than the target will achieve the target.

All targets are decimal values. For example, an average load time of 4.5 is 4 minutes and 30 seconds.

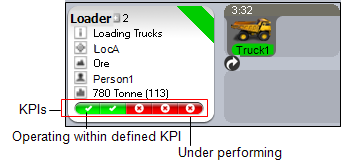

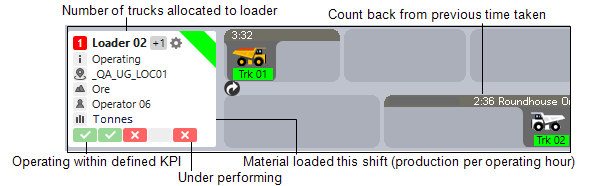

In Data Acquisition, the Loader and Trucks Panel and Location Activity Panel panels show loader units with defined KPIs. They are displayed as:

- Red. Indicating that targets have not been met. The unit is under performing for this KPI.

- Green. The unit is operating within the defined KPI targets.

For example, if a loader is servicing two trucks model types, one with a smaller capacity than the other. Depending on the truck model, the load time for the truck will vary. Thus, you will need an average load time KPI defined for the:

- Small capacity truck.

- Large capacity truck.

With the other three KPI types (average queue time, loader efficiency and production rate) this is a total of five KPI types that would be applied to the loader.