Cash Flows

Cash flows allow the user to specify an incremental Reward or Penalty for each tonne/cubic meter/ounce of material sent to a Destination.

Cash Flows help the user to have better control over the fleet allocation, prioritising more profitable movements.

If two rules satisfy the same condition, then the cash flow is the sum of values in each rule.

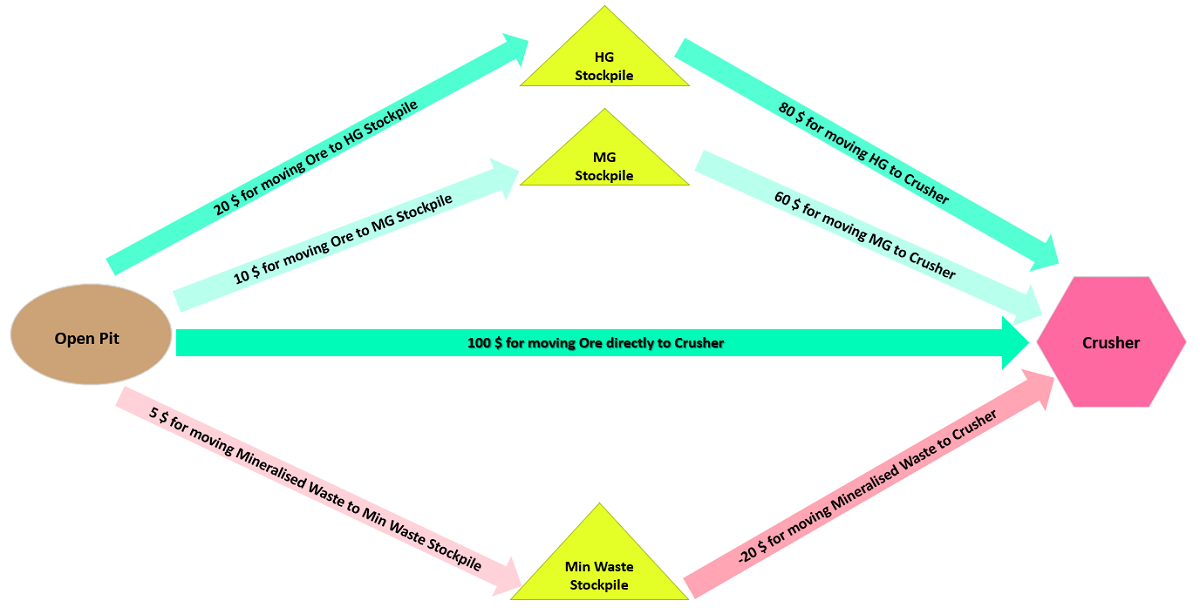

Cash Flows example

This chart shows an example of the cash flow allocation for prioritising different ex-pit ore movements, namely:

-

The reward for direct ore movement from the Pit to the Crusher is $100, which makes this transaction the most profitable and therefore prioritised by the optimiser.

-

The reward for feeding a unit of high-grade ore from the Pit to the HG stockpile is $20, and medium-grade ore to the MG stockpile is $10, which prioritises moving of the high-grade over medium-grade material.

-

Similarly with the reclaiming of HG and MG stockpiles: since the reward for feeding the Crusher with high-grade material is higher than that for feeding the medium-grade, the HG stockpile will be given greater preference to reclaim.

-

Finally, the mineralised waste movement is the least profitable in comparison to ore flows, but may still be applicable in some periods, such as when high and medium grade ore is not available. If a negative cash flow is placed on this movement, feeding mineralized waste to the Crusher will be penalized because, for example, it may cost more in resource usage (machinery hours, fuel consumption, etc.) than will be received after processing a unit of this type of material.

Stockpiles and Crushers Cash Flows

Stockpiles and Crushers Cash Flows

Cash Flow rules for Stockpiles and Crushers define a dollars-per-unit rate on material types conveyed between Sources and Destinations.

Once a rule is configured, the rate is specified in the Calendar.

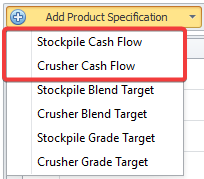

Adding Cash Flows for Stockpiles and Crushers

-

Set the Source(s), Material(s), Destination(s), and unit (Quantity Field) on which to apply the Cash Flow.

Example of Crusher Cash Flow configuration

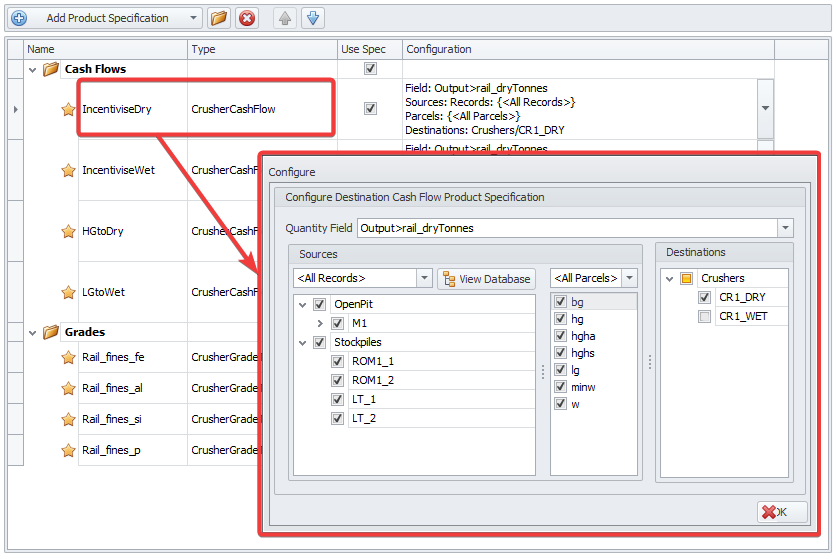

Cash Flows by Plant

The example below allows the user to control the priority of the Wet plant and Dry plant and preference certain materials into each plant.

-

$30 reward per railed tonne from the Dry plant.

-

$30 reward per railed tonne from the Wet plant.

-

$1 reward per railed tonne of HG from the Dry plant.

-

$1 reward per railed tonne of LG from the Wet plant.

Cash flows on Wet plant, Dry plant, HG feed, LG feed

The sum across these values means that HG returns ($40) from the Dry plant and ($30) from the Wet plant, whereas LG returns ($30) from the Dry plant and ($40) from the Wet plant. As such, the optimiser prefers to sent HG to the Dry plant but can top up the Wet plant if required.

Cash Flows by Material

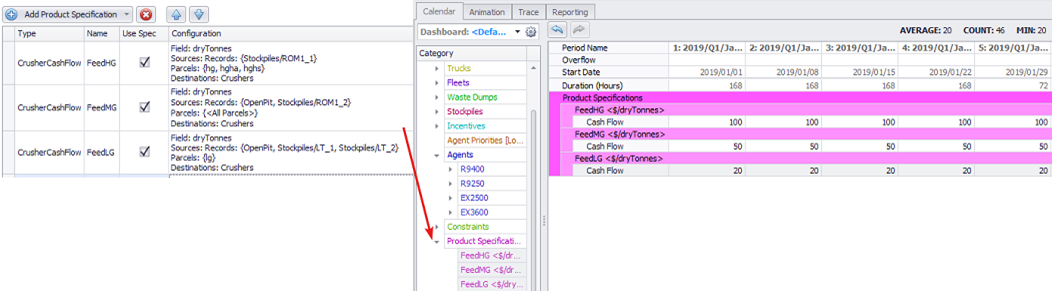

This example prioritises feeding HG first, then MG, then LG, to maximise the returned metal content.

-

$100 reward per feed tonne of HG.

-

$50 reward per feed tonne of MG.

-

$20 reward per feed tonne of LG.

Cash flows for greedy metal recovery

Cash Flow Values

Cash flow values are strictly relative. Setting all fields to "10" is the same as setting all fields to "10000".

Users are encouraged to pick values that express the relative importance of each transaction. For example, if high grade yields twice the revenue of low grade, give it twice the cash flow.

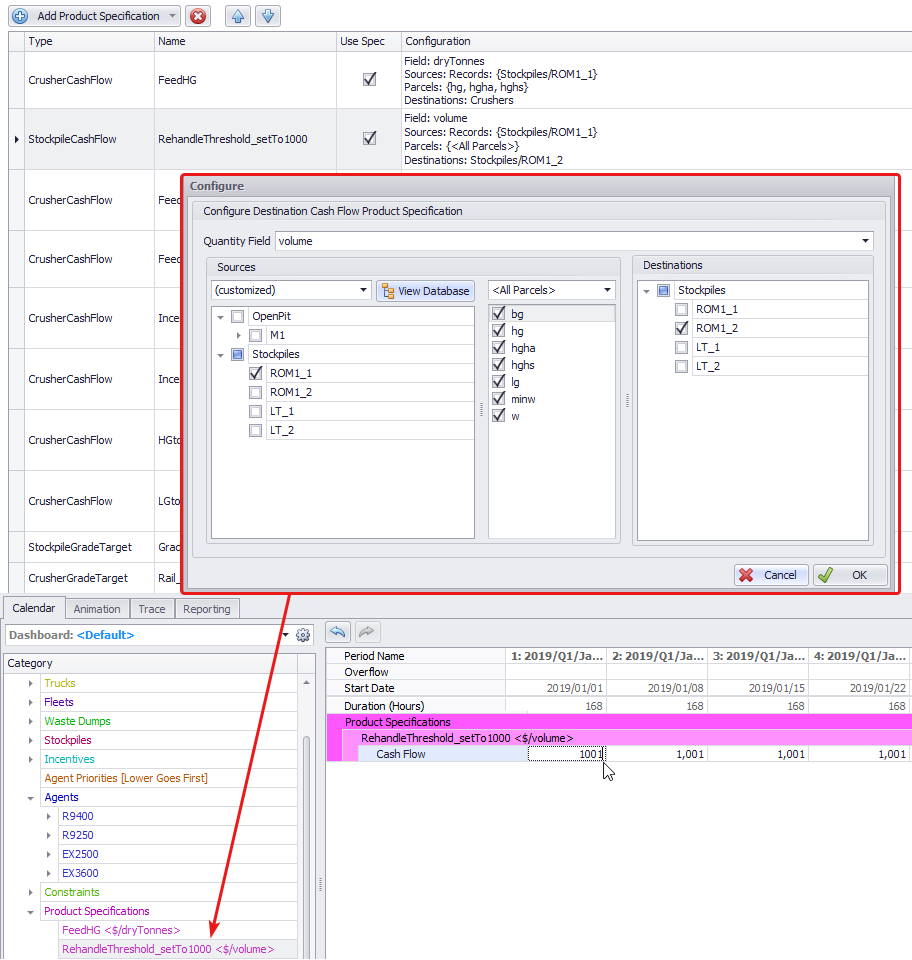

Cash Flows between Stockpiles

Movement between stockpiles incurs a default negative cash flow of (-1000) per bank cubic meter. This prevents the optimiser from going into circular rehandle loops.

To enable movement between stockpiles:

-

Press Add Product Specification button and from its drop-down select "Stockpile Cash Flow".

-

Name it as "RehandleThreshold_setTo1000", for example.

-

Set the units to “mining_” volume or Tonnes, depending on the units you schedule the material in these stockpiles.

-

Select the Source and Destination stockpile.

-

In the Calendar, set the cash flow to 1001.

Configuring cash flow between stockpiles

Notes

Be careful to only allow one-way passage of material between stockpiles. Do not incentivise the optimiser to engage in non-productive rehandle.

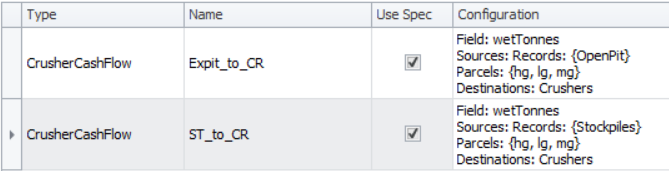

It is recommended to split the Crusher Cash Flow into two:

-

one for the Direct Expit material movement to the Crusher,

-

one for the Stockpiles to the Crusher rehandle.

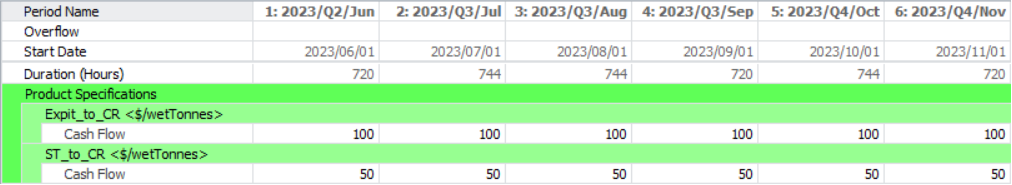

Then, in the Calendar, assign to the Cash Flow from Stockpiles value of = 50 and to the Cash Flow for from Expit movement = 100. This will allow you to incentivise the one which is more profitable.

Product Specification setup

Setting Stockpiles and Expit Cash Flows in the Calendar