Second Site

The Second Site setup allows users to bring external movements from one or more sources and incorporate them into a Central APS model. This could be used when multiple surface mines and/or underground operations are planned separately but provide joint feed to a common Central Processing Plant.

External Model Export

For sites wanting to combine multiple APS models, using this method removes the need to create any special reports. Also, if the same naming convention for Fields and Processing Paths has been used, APS will do the field mapping automatically.

Final Configuration

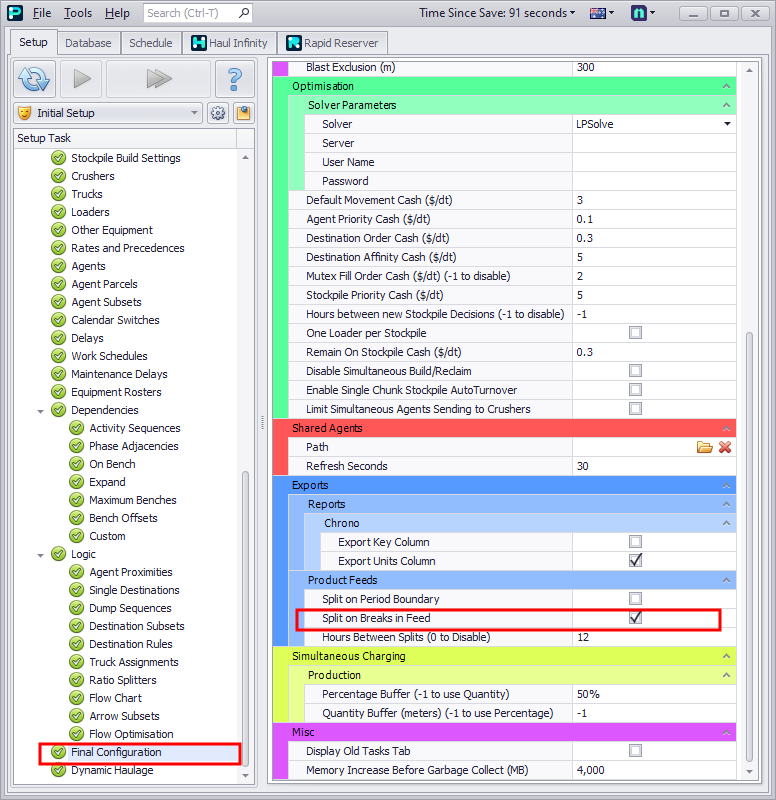

By default, APS will export periods as defined by the Calendar. The Final Configuration step allows users to set the intervals to break up the material feed from the External site to the Central site.

Review Product Feed intervals settings in the Final Configuration step

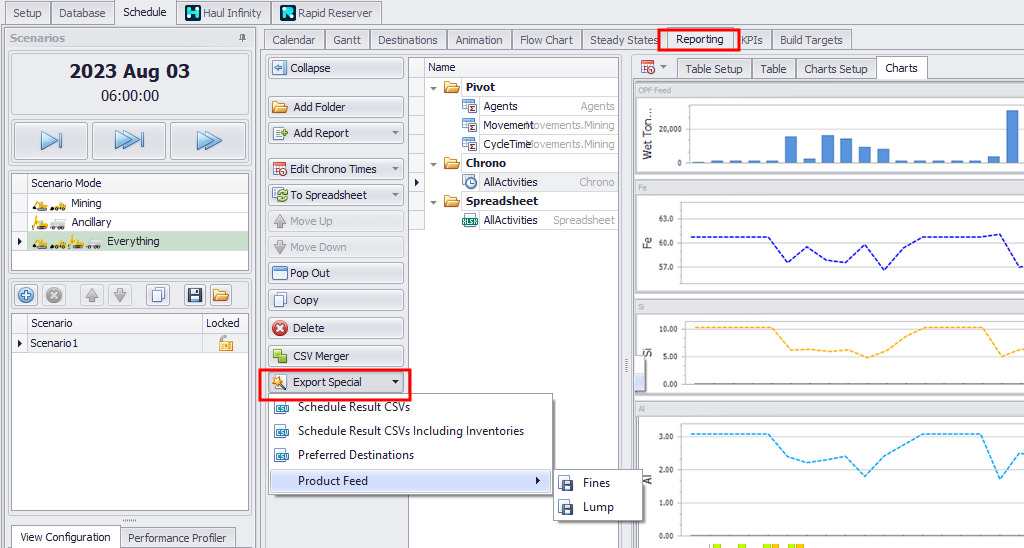

Export Product Feed

Run the Schedule and select the Reporting tab. Click the Export Special button and select the product stream you want to export. This export will be used in the Central model to simulate an external feed source.

Schedule > Reporting tab > Export Special button dropdown > “Product feed” option

Make sure you are exporting in a relevant mode. It is recommended to export only from “Everything” mode, as the result from any other mode may not constitute a valid schedule.

The exported product feed will be saved in a selected directory as a “.prodFeed” file.

Central Model Setup

The following steps are required to be completed on the Central model, which is receiving material from the External model for consolidation.

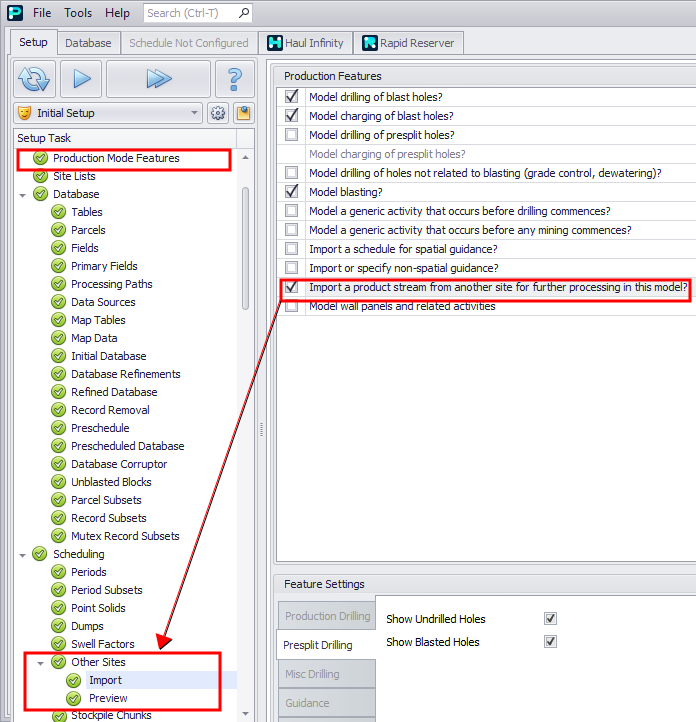

Production Mode Features

Enable the Import a product stream from another site for further processing in this model flag in the Production Mode Features step. This will enable an extra setup step (Other Sites) for supporting an external feed source:

Enable Importing a product stream from another site for further processing in this model

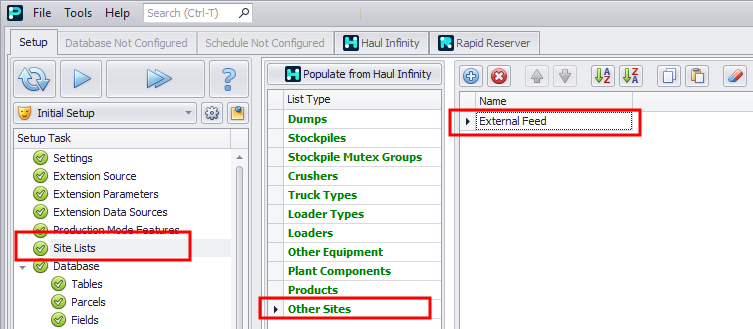

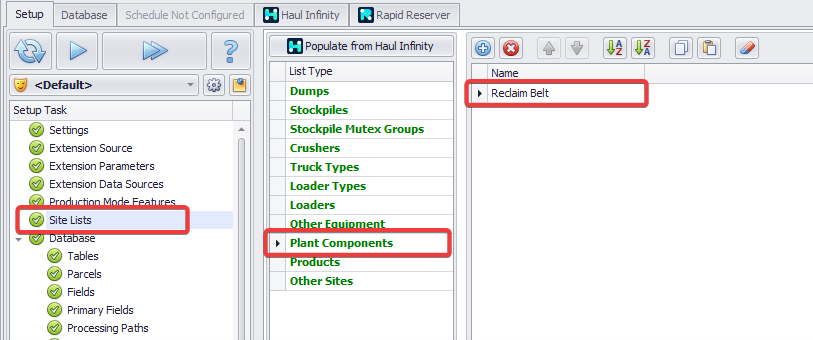

Site Lists

-

In the Site Lists step, add an external feed source to the Other Sites list. APS will automatically create a temporary stockpile to act as an interim storage facility between the External site and the Central processing plant. Note: This stockpile will need to be created in Haul Infinity.

Add a Second site stockpile in the Site Lists step

-

Optional: If the material from the Other Site is automatically reclaimed via a conveyor system, a Plant Component can be used to control the reclaim rate to the central plant. This component is applied in the flow chart and can be used with Flow Optimisations.

Create a Second Site Plant Component for the other sites in the Site Lists step

Other Sites

-

Import

-

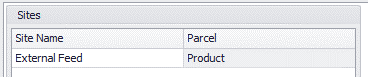

Shows a list of all Other Sites configured in Site Lists.

-

Select each Other site and select the Parcel type to assign.

-

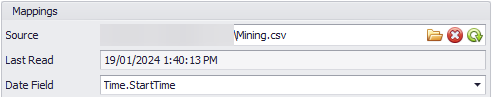

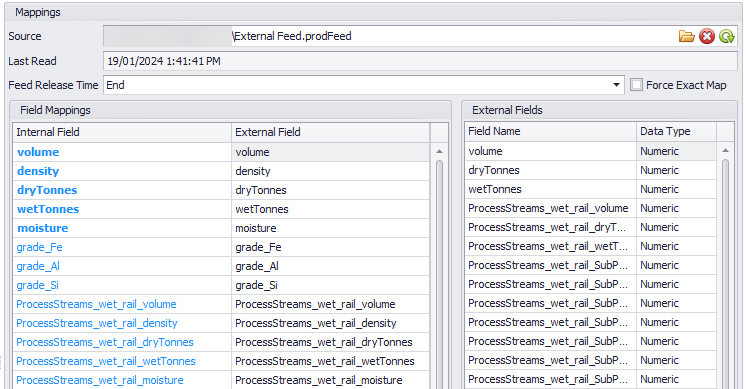

Source – Select the source file to import (“*.csv” , “*.prodfeed”). Depending on the file type selected the Date field will behave differently.

-

Provides the choice to select Feed Release Time at the Start or End of a period. This refers to when the material becomes available for processing.

-

Provides a check box to ‘Force Exact Map’. This forces the external model to have the exact same setup for Fields and Processing Paths. Note: The external model may have more fields than the Central model, but must have everything the Central model has.

-

Provides a dropdown to select a column from the data to use as the release time.

-

Field Mappings

-

Match External Fields from the imported data to Internal fields from the current APS model. This can be done by the drag and drop method, or by selecting the Internal Field and double clicking on the External Field.

-

Note: If column headers are similarly named as the APS model, then the mapping will happen automatically.

Sites

Mappings

Prodfeed Import

CSV Import

-

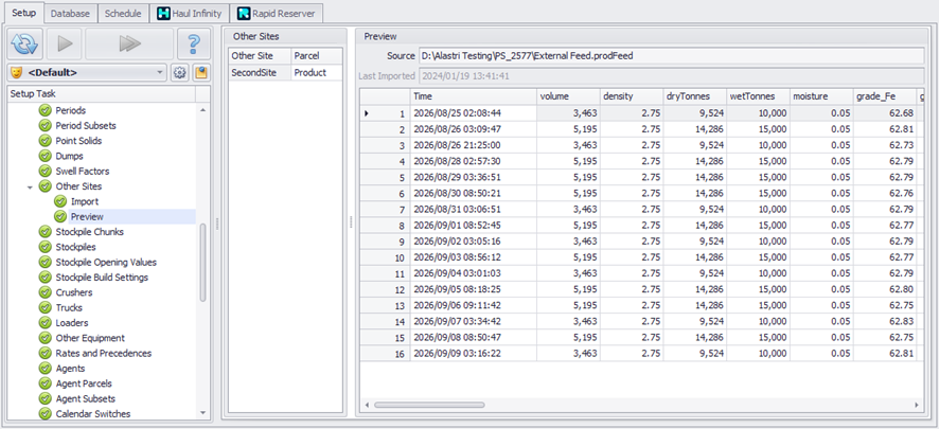

Preview – Provides a preview of the imported data.

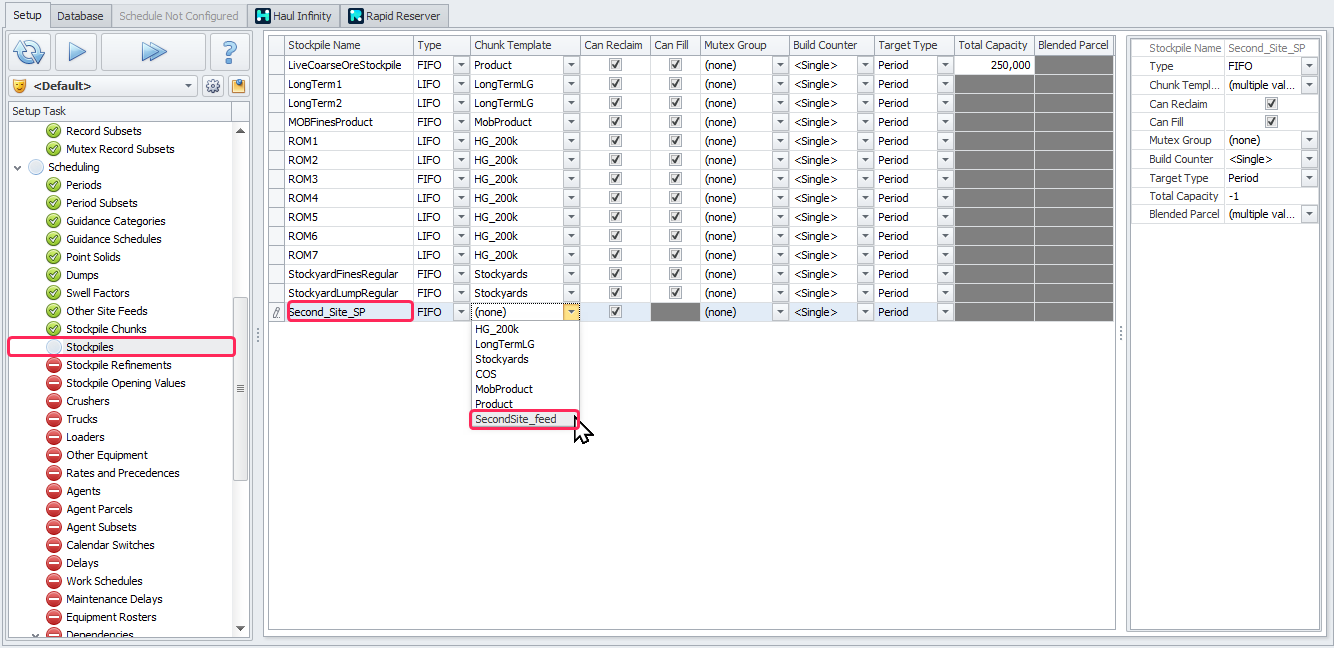

Stockpiles

In the Stockpiles step a new stockpile will automatically be created and displayed in blue:

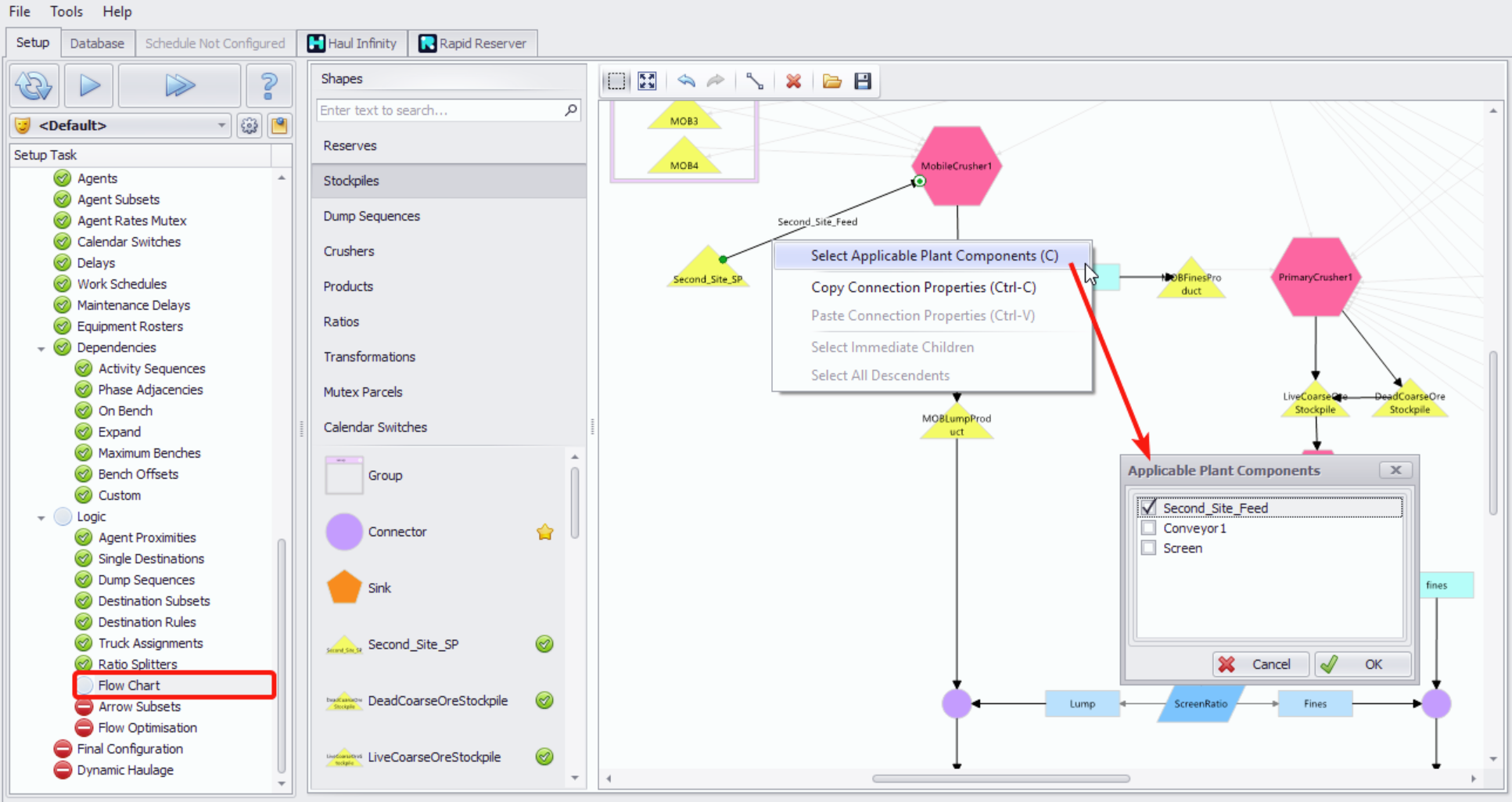

Destination Rules and Flow Chart

Depending on how the material is transferred from the Other Site stockpile to the next destination, will impact on how the rest of the model is setup. Regardless of the method selected, the stockpile will need to be added to the Flow Chart.

If the material is being rehandled by a Load & Haul fleet, then the Destination Rules and Truck Assignments will need to be updated.

If the material is being automatically reclaimed, then the source stockpile will need to be manually connected to the destination in the Flow Chart.

Optional: Right-click on the manually created arrow and choose the “Select Applicable Plant Components” option to select the second site plant component.

Flow Chart step > Stockpiles > Connector Mode icon > Select Immediate Children > right click > “Select Applicable Plant Components” option > Second_Site_Feed flag

Notes

-

Tonnes from the External source will only become available at the start/end of the period in the import file. Meaning if the imported periods are too long, then the interim stockpile may go empty, and the crusher may go on standby.