Reconciliation

Reconciliation is the process of reconciling the claimed grade and material mined against the mill or plant- i.e. the actual values recorded at the mill. Reconciliation checks that targets have been met, the validity of the orebody model and that the planned life of the mine will be met.

Before reconciliation

Before the end-of-period reconciliation process is undertaken:

- Materials Management Geologist has completed daily procedures of checking that all the transactions have been entered correctly. They will also check that the most up-to-date and the most reliable grades have been entered for the transactions. All validation errors have been corrected and daily production reports have been run.

- The surveyor has surveyed the stocks and values have been entered via Stockpile Surveys.

- At the end-of-period, the Senior Geologist has reviewed movements, grades and stocks for the period and run grade control and stockpile reports to identify any inconsistencies in the data.

- The envelopes, necessary for reconciliation to be undertaken, have been defined. Grade control envelopes are defined in the Reference Data service.

When all the movements, quantities and grades accurately reflect what was understood to be mined during the period, the grade control process is ready to take the next step- reconciliation.

Envelopes

An envelope represents one of the stages in the material's journey from its source to the final destination. Each envelope has a name and an order number. The name reflects the type of locations in the group. When the envelopes are displayed in Reconciliation, the order number defines its sequence in the display - the first mining stage (1) on the left through to the final stage (n) on the right.

An envelope is a token defined in the Reference Data service. In this case, it is an attribute token. An envelope must be defined before locations can be assign to it. Each envelope can be assigned one to many locations. LocA and LocB, for example, are primary locations and belong to the Primary envelope; StockA and StockB are stockpiles and belong to the Ore Pad envelope.

In Reconciliation, the envelopes, and their associated group of locations, represent the stages in the mining process where the movements in and out of the envelope are reconciled. The normal reconciliation procedure would be to reconcile the Mill Cone envelope with the mill head grade end-of-period report, then balance the movements and grade of Ore Pad and finally Primary.

Claimed and Actual

Reconciliation works with two types of information or values.

They are:

- Claimed. As mining progresses during the shift, all loading, hauling and dumping movements are recorded as events in the database. These are the claimed quantity values. Before starting reconciliation, the Materials Management Geologist enters the claimed estimate and assay grades. Every effort is made to ensure that the claimed values are a true representation of the quantity and grade of the material mined.

The material:

Into an envelope. The sum of all the material dumped at all the locations in an envelope represents the claimed quantity and grade of material into the envelope.

Out of an envelope. The sum of all the material loaded and hauled from all the locations in an envelope represents the claimed quantity and grade of material out of the envelope.

Because of the complexity of mining, the claimed values present the best estimate of the material that was mined.

- Actual. At the end-of-period, the mill reports the quantity and the head grade of the material it processed. This is the most factual information that is available.

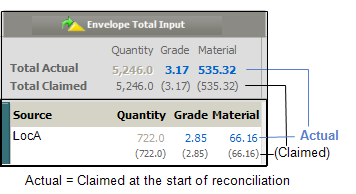

In Materials Management, when you start the reconciliation process the actual values are equal to the claimed values. When the processing plant reports the actual quantity and grade of the ore processed, the values for each envelope are adjusted, by the Senior geologist, in an effort to present a realistic picture of the material movements for each of the envelopes.

At the end of the reconciliation process, the aim is to have the actual quantity and grade values for each envelope as close as possible to reality.

Element definition

An element is one of the products of mining. Defining elements includes:

- Elements are configured in the Reference Data service, Groups | Materials Management | Element.

- ElementA , for example, is defined by two attributes, Unit of Measure = ppm and Primary = 1.

- Unit of Measure. This value can be either ppm or %.

- Primary. If the element is the:

- Primary producing ore type, the Primary = 1.

- Not a primary ore type, the Primary = 0.

At a gold-copper site, for example, gold Primary = 1 and copper Primary = 0. All other elements, other than the primary element, have Primary = 0.

The Primary value is used to define the element displayed in the first column in Reconciliation.

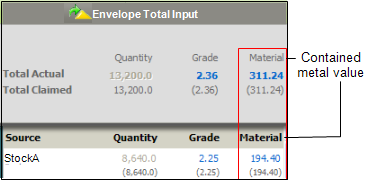

Contained metal value

In Reconciliation, the quantity of material and the grade of the elements are used to calculate the contained metal value for both the claimed and actual values. The defined Unit of Measure for the element is taken into account when computing the value.

If the Unit of Measure for an element is:

-

ppm. The contained metal value is calculated in international troy ounces (ozs or t ozs), where 1 troy ounces = 31.1034768 g.

Where:

Material = (Quantity x Grade) / 31.1034768

-

%. The contained metal value is a percentage of the quantity.

Where:

Material = (Quantity x Grade) / 100

Units of measure are defined in the Reference Data service.

Reconciliation period

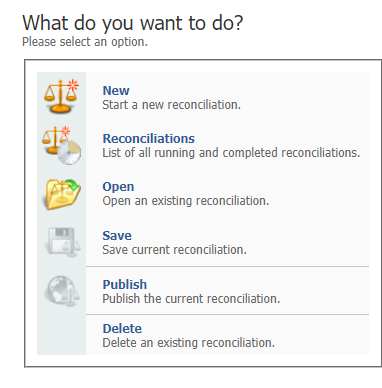

Before you can work with Reconciliation you need to define a reconciliation period - known as the period of interest. Reconciliation is often undertaken over a four weekly period. Click the Reconciliation option on the toolbar menu and the What do you want to do? dialog will open.

This dialog includes the following reconciliation period options:

-

New Select to define a reconciliation period. Each period has a name, start date and end date.

- Open. Select one of the previously defined reconciliation periods

- Save. To save adjustments to the database. This is an important step. It ensures that the current reconciled quantity and grades are available to the Reporting service.

- Publish. To publish the reconciled quantity to make them available to the Reporting service. When a reconciliation period is published the claimed quantity and grades are not overwritten: only the actuals are written to the database.

- Delete. To delete the current defined reconciliation period.

Once a reconciliation period is defined or selected, the reconciliation window will open.

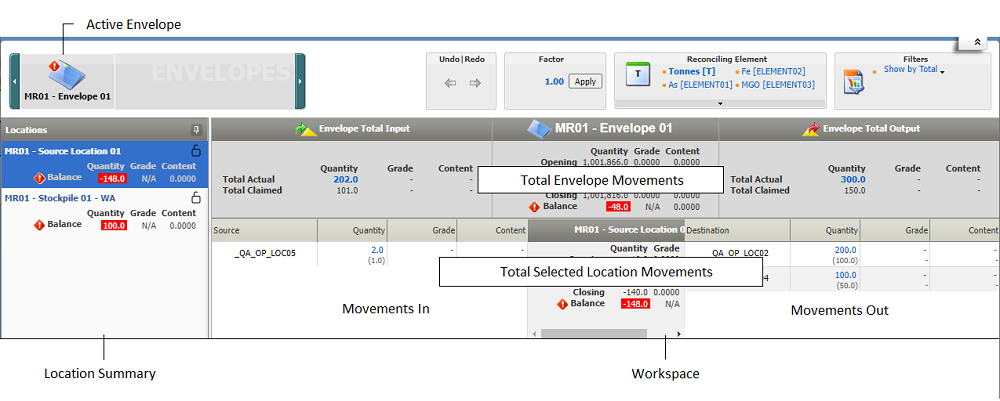

Reconciliation window

The reconciliation window is displayed when a reconciliation period is defined or opened. The window will open, by default, with the envelope with the highest order number, active. This is often the mill cone or equivalent envelope.

The reconciliation window is made up of three main panes:

- Header. The header, below the services toolbar, includes the following:

- Far-left. The envelopes are displayed as icons. They are presented in the sequence defined by the Order attribute: the lowest Order to the left and the highest to the right in the sequence.

- Mid-right. Reconciling Element. Select either quantity or element to make the actual values of either available for editing. Select, for example, either MeasureA or ElementA.

The quantity and element values for a movement are displayed: the actual value at the top (in blue, if it is available for editing), and the claimed value, bracketed, below.

Only actual values can be edited: claimed values are events saved in the database. A claimed quantity should be edited in Event Editor if an error has been identified.

- Filters. Select to Show by Total, Day or Transaction. This changes the movements displayed in the Movements In and Movements Out, in the location workspace display. For each location in the active envelope, display summarising the:

- Total movements into and out of the envelope.

Daily movements into and out of the envelope.

Transaction for each location in the active envelope.

- Location summary. To the left and below the header. This pane lists all the locations defined in the active envelope. Each location presents a summary of the change of stock for the reconciliation period. It is calculated using the quantity of material in, minus the quantity of material out of the location for the period.

- Workspace. Displays the following main areas:

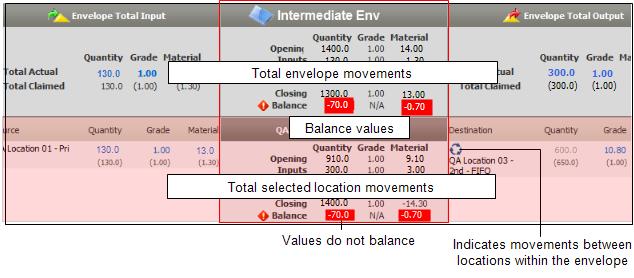

- Total envelope movements. At the top of the workspace is the total inputs, total envelope and total output quantity, grade and material for the whole envelope for the reconciliation period. Actual values are available for editing: the claimed vales are not available for editing.

- Total selected location movements. Below the total envelope movements is a summary of the inputs, current stock and outputs for the selected location for the reconciliation period. The display changes according to the filter that has been selected. The change in stock is the material in minus the material out for the active location.

The Material value is the contained metal value calculated using the quantity, grade and the Unit of Measure for the element.

The contained metal value is calculated using the quantity, the grade and the unit of measure (ppm or %) of the element to give a realistic value of the material.

Header options

The header contains a number of options. The option selected changes the display in the location summary and the workspace:

-

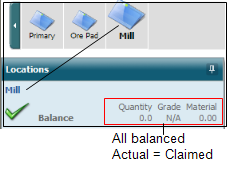

Envelopes. When you first open Reconciliation, the envelope defined with the highest order number is displayed. This may be, for example, a Mill envelope. The active envelope is displayed with the largest icon.

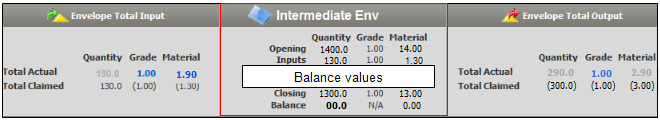

Before any changes are made to the quantity or grade, Actual = Claimed by default. For the quantity or material to be balanced, the:

Opening value + inputs - outputs - closing quantity= 0

Where closing is the surveyed value for the envelope and the opening value is the previous end-of-period envelope survey.

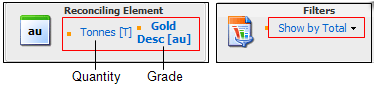

- Reconciling Element. There are two options available for this function. Select between the options to make either active:

- Quantity. By default the workspace shows the quantity values - Tonnes or tons, for example. When the measure is active, the actual quantity is available to be edited.

Element. Select one of the elements from the drop-down list of defined elements for the site. With Element active, the actual grade is available to be edited.

Claimed values cannot be edited.

- Filters. The filter options changes the display of the input totals. The options are to Show by:

- Total. A sum of all the transactions from the source to the destination for the period. The image below has this filter selected.

- Day. Display of the daily totals for the selected reporting period.

- Transaction. Display of the actual transactions for the selected reporting period.

Values are balanced when:

Opening + Input - Output - Closing = 0

Workspace

The balancing of quantity and grade for the stocks usually starts at the final or Mill Cone envelope. The procedure is to work back from the Mill Cone through the envelopes to the primary location envelope. The first pass may be to reconcile the quantity. When you are satisfied that the quantity for all envelopes represents a realistic measure of what was mined, the same process is repeated for the grades.

Reconciliation may entail many passes before you are satisfied with the result. At each envelope the process of balancing the actual quantity and grade values with claimed is undertaken.

Before you begin working in Reconciliation make sure that the:

- Materials Management Geologist has completed reviewing the mined movements for the period of interest. This includes both the claimed quantity and grade of the material for the period of interest.

- Surveyor has surveyed the appropriate stockpiles and they have been entered into the database via the Stockpile Survey option on the toolbar menu for the period of interest.

Some of the features of the reconciliation window that you will use are:

- Location summary. Lists all the locations in the active envelope. By default, the first location in the list will be displayed in the workspace with the totals for the envelope. Click on another location in the list to change the workspace display.

-

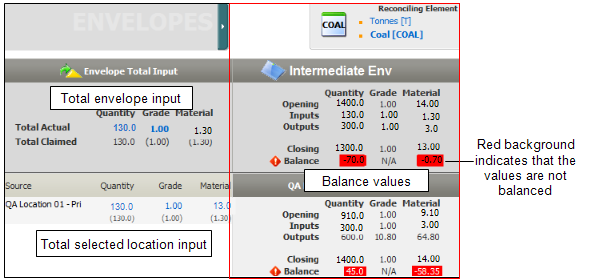

Workspace. The workspace is made up of a number of areas. From left to right they are:

- Input. The total input to the active envelope is displayed at the top and the total input to the selected location at the below.

- Balance values. This is a display of the balance values of the active envelope at the top, and that of the selected location below.

- Output. The total output from the envelope during the period of interest is displayed at the top, and that of the selected location below.

When the end-of-period mill head quantity and grade become available, the reconciliation process can begin.

Any material movements between locations within an envelope are not included in totals.

The mill head quantity and grade, and stockpile surveys are the factual information on which reconciliation is based. Values displayed in the workspace that do not balance are displayed with a red background. The aim of reconciliation is to have these values balanced.

If the magnitude of a negative Balance value is within reasonable bounds, it may be acceptable. For example, -200 t in a 60,000 t period report may be of no importance.

Any changes made to the actual Total Output quantity or grade are distributed to the individual locations in the envelope based on the proportion of their output in the total output for the envelope.

Only actual values can be edited: claimed values are events in the database.

To edit the grade you can change either the actual Grade or the actual Material. Changing either of these is, in effect, changing the grade.