Tonnes kilometres is a key performance indicator (KPI) which is widely used throughout the resources sector. The calculation is based on the distance between the source and destination of the material movement and the tonnes carried by the equipment unit.

For example:

If an 80 tonne truck moves material over a distance of 1.5 kilometres, the tonnes kilometres for each movement would be 120.

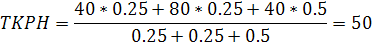

Tonnes kilometres are usually expressed against the operating hours of the equipment unit. In the example above, if the truck did 6 trips over a 3 hour period, the tonnes kilometres per operating hour would be:

(6 * 120) / 3 = 240

However, in real life, TKPH is a function of the maximum allowed internal operating temperature of a tyre (the MaximumTreshold attribute defined in the Reference Data, see below).

The calculation may vary, based upon the TKPH measure used (see 'TKPH Calculations Based on TKPH Measures' below).

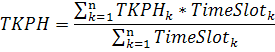

Since the time interval for which TKPH is calculated can be spread over many material movement cycles, the TKPH for each cycle must be calculated. The final TKPH is a sum of the partial TKPH results.

| 15:00 | 15:15 | 15:30 | 15:45 | 16:00 | 16:15 | 16:30 | 16:45 | ||||||||

| Start Time | MM Cycle 1 Dump | MM Cycle 2 Dump | MM Cycle 3 Dump | ||||||||||||

| TKPH1 | TKPH2 | TKPH3 | |||||||||||||

| TKPH | |||||||||||||||

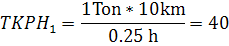

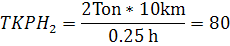

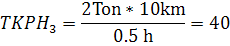

For example:

| 15:00 | 15:15 | 15:30 | 15:45 | 16:00 | 16:15 | 16:30 | 16:45 | ||||||||

| Start Time | MM Cycle 1 Dump | MM Cycle 2 Dump | MM Cycle 3 Dump | ||||||||||||

| TKPH1 | TKPH2 | TKPH3 | |||||||||||||

| 10km, 1Ton | 10km, 2 Tons | 10km, 2 Tons | |||||||||||||

TKPH Calculations Based on TKPH Measures

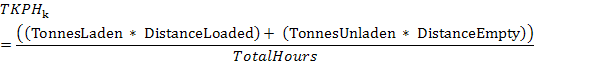

In reference to the selected measure, the TKPH for a cycle can be calculated in the following ways:

- Standard (simple) TKPH

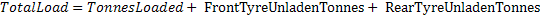

TonnesLaden – Tonnage being hauled

DistanceLoaded - Distance the tonnage was hauled, in kilometres

TonnesUnladen – Tonnage when the truck was empty

DistanceEmpty – Distance travelled when the truck was empty

TotalHours – Cycle duration

- Simple TONKM

Alternate to Standard TKPH provided for backward compatibility with the Pitram Portal. (Seems to be the same calculation as by Standard TKPH)

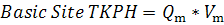

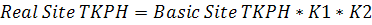

- Michelin Real Site TKPH

- First the Basic Site TKPH must be calculated:

- Now the Real Site TKPH can be calculated:

- The length of cycles exceeding 5 km – K1 coefficient

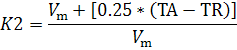

- The ambient temperature – K2 coefficient

Qm - average load per tyre

Vm - average cycle speed in KM per hour

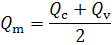

Qm - average Load per Tyre

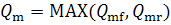

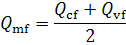

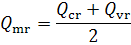

Qm is calculated for both the front and rear tyre. Then the maximum value is used.

where:

Front Qm :

Rear Qm :

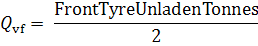

Qv - load per tyre in ton on an unladen vehicle (Qvf and Qvr)

Front Qv (2 tyres on the front axle):

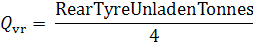

Rear Qv (4 tyres on the rear axle):

where:

FrontTyreUnladenTonnes – reference data parameter

RearTyreUnladenTonnes – reference data parameter

Qc - load per tyre in ton on a laden vehicle (Qcf and Qcr)

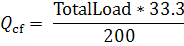

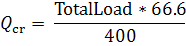

Assuming that the distribution of the total load corresponds to 33.3 % on the front axle (single tyres) and 66.7% on the rear axle (twined tyres).

Front Qc (2 tyres on the front axle)

Rear Qc (4 tyres on the rear axle)

where:

Vm - average cycle speed:

where:

L – Cycle length in km

H – Cycle duration in hours

To obtain the real site TKPH, two more factors must be taken into account:

This coefficient is defined in the specification. Its values are hardcoded in the source file TKPHCalculations.cs.

where:

TA – the ambient temperature.

The specification does not define what to do if Vm is out of scope. For now if Vm is less than 10 then 10 will be used and if Vm is bigger than 50 then 50 will be used.

The specification defines that if TA < 15 °C, the K2 coefficients shown in the shaded area of the table on page 102 will be used. K2 for TA < 15 °C can also be calculated using the equation above where TA = 14.

The specification does not define what to do if K2 is greater than 45 °C. For now the given equation will also be used to obtain K2 for TA > 45 °C.

TR – the reference temperature, 38 °C

- Finally calculate the Real Site TKPH:

Real Site TKPH = 0 if the result of the previous equation is less than 0.