Repair States

Repair states are used to monitor the progress of equipment in the Maintenance workshop. For example a unit might have had a primary state of Down for a number of hours. While in this state, the unit can also be associated with repair states which help identify what took time to fix. For example:

Waiting for fitter -> Diagnosis -> Waiting for parts -> Repair -> Available.

This example could show that the majority of time was spent waiting for parts, meaning spares supplies may not be adequate.

A unit does not have to spend time at all stages, but can move from Diagnosing to Waiting for Fitter, for example.

Repair states are assigned in Data Acquisition via either:

- Right-click on an icon or in the Equipment pane in the data group. Select Set Repair Status and select the appropriate status.

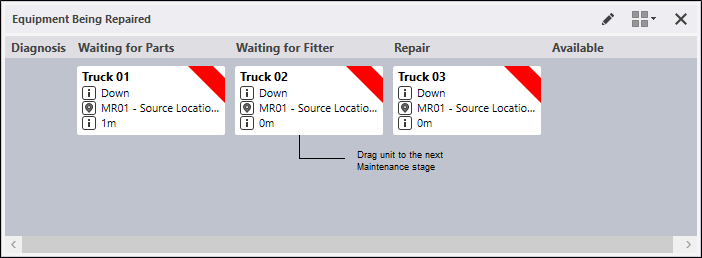

-

Maintenance panel on a canvas.

Typically, repair states are assigned by the Maintenance Department to a equipment unit that was in their care. Repair states can only be assigned if a unit is in a Down status.

Assigning repair states, for example, of Diagnose, Wait Parts, Wait Fitter and Repair as it progresses through Maintenance is an excellent way to monitor the maintenance process in relation to the unit type and the repair procedures.

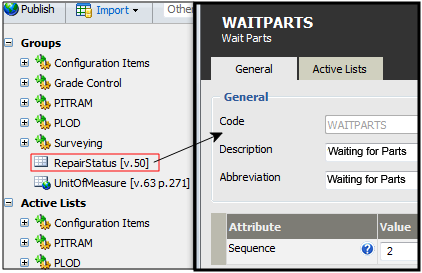

Repair states are defined in Reference Edit in the Groups | RepairStatus reference data group.

Each RepairStatus token has a Sequence attribute. This attribute defines the sequence of the repair status in the report that is generated - a sequence of 1 to n (top to bottom).

If, for example, the RepairStatus token has a:

- Code = WaitParts.

- Description = Waiting for Parts.

- Abbreviation = Waiting for Parts or

- Attribute, Sequence = 2. Waiting for Parts will be the second column in the panel.

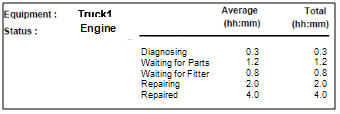

Maintenance reports such as Mean Time Between Failure and Repair Status are available in the Reporting service. The latter report identifies the time spent at each of the defined maintenance stages.

These reports can be used to identify where bottlenecks in the system occur and where improvements can be made to the maintenance process. As a result, measures can be undertaken to improve the time taken to repair a failure.