Steps Logic

Overview

If Destination logic tells you where material can go, Steps Logic tells you how it will get there, what intermediate steps it will go through before reaching the ultimate destination, and what equipment will be used (it is here that the fleet used is specified).

Steps Logic controls how material can move through the site during a given period. It has two potential uses:

-

Convert a single schedule transaction into one or more final transactions (steps).

-

Assign the fleet to each final transaction.

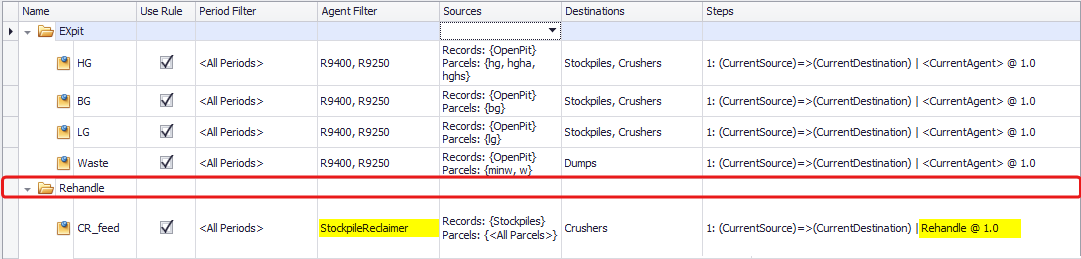

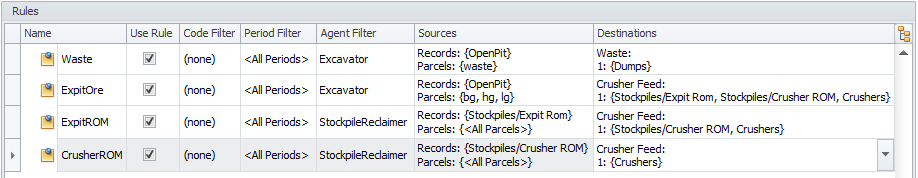

Step Rules Filters

Each rule lists the Steps for transactions that match its filter criteria:

|

Filter |

Description |

Note |

|---|---|---|

Name |

Give each rule a unique name, and group in folders. |

Avoid using commas in the Step Rule name, because when exporting future reports to CSV, the commas result in misalignment of the columns. |

Use Rule |

|

|

Period Filters |

Used to select when individual rules will be applied. Potential Use Case: Differentiate pre- and post- plant commissioning. |

|

Agent Filters |

Used to select what Agents the rule applies to. Potential Use Case: Differentiate between autonomous and non-autonomous haulage. |

StockpileReclaimer is a default Agent created by the software to reclaim from Stockpiles to feed the Crusher. It doesn’t work in a pit and should be unticked from the list of Expit Agents, and used for Stockpiles Rehandle only. |

|

Filter |

Description |

Note |

|---|---|---|

Source and Parcel Filters |

Used to select what sources & parcel the rule applies to. Potential Use Case: Differentiate Ex-pit from Rehandle fleets. Agents evaluate whether the record source/parcel being mined is included in the list. |

|

Destinations |

Used to select what destination the rule applies to. Potential Use Case: Differentiate which trucks can tip directly into which crushers. |

Note that the Destination Filter is only used to evaluate schedule transactions. To deactivate a destination, remove references to it from the Destination Logic. Steps Logic Destination Filters have no effect on the scheduled destination. They are filters only. See the Destination Logic to change the destination. |

Steps |

|

|

Setup Step Logic

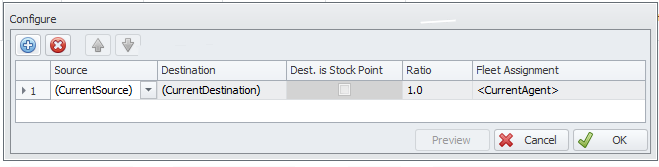

Configure User Interface

| Column | Description |

|---|---|

|

Source |

Current Source refers to source chosen by the agent. This can be changed to another source for more complex setups, as described below. |

|

Destination |

Current Source refers to source chosen by the optimiser. This can be changed to another destination for more complex setups as described below. |

|

Dest. Is Stock Point |

Option allows interim destination to be used as a stock point. This means the destination acts as a stockpile and can have varying stock levels from period to period. This will also automatically create extra step logic from the source to the stock point and from the stockpile to the final destination. |

|

Ratio |

How much of the original source material is using this step. |

|

Fleet Assignment |

Current Agent refers to the agent chosen by the optimiser. This can be changed to another fleet as required for each step. |

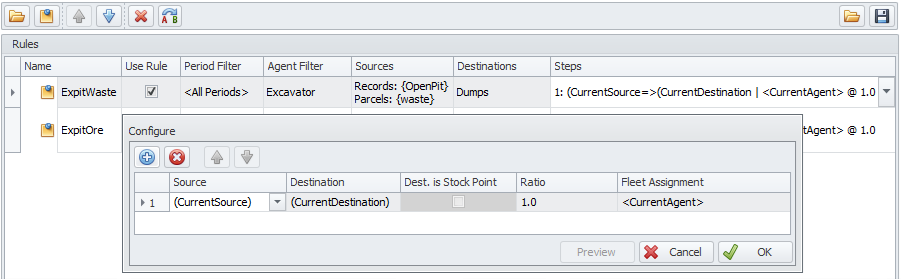

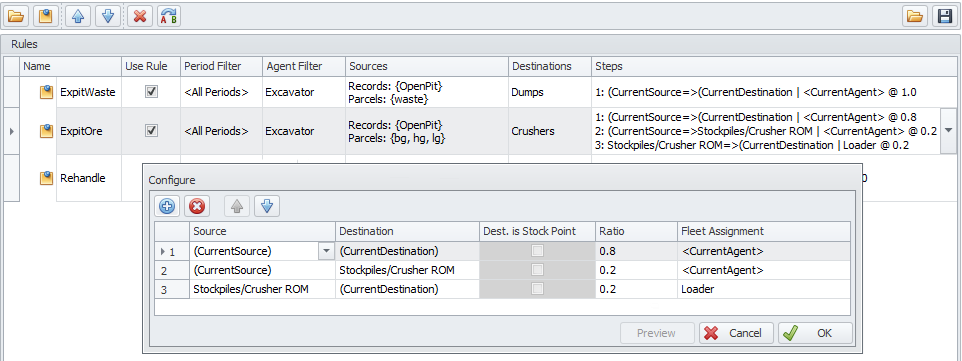

Waste Example

All Expit waste will have one Source and one Final Destination using the Current Agent Fleet.

In some cases, there may be no need for any changes. All Expit waste is going directly to its final destination using the Excavator Agent and its assigned fleet.

Steps Logic (Top)

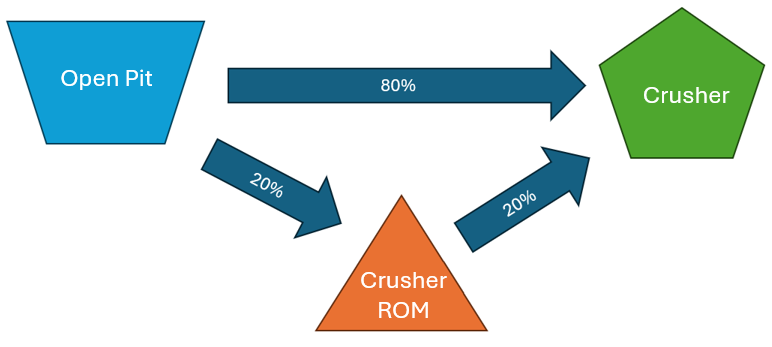

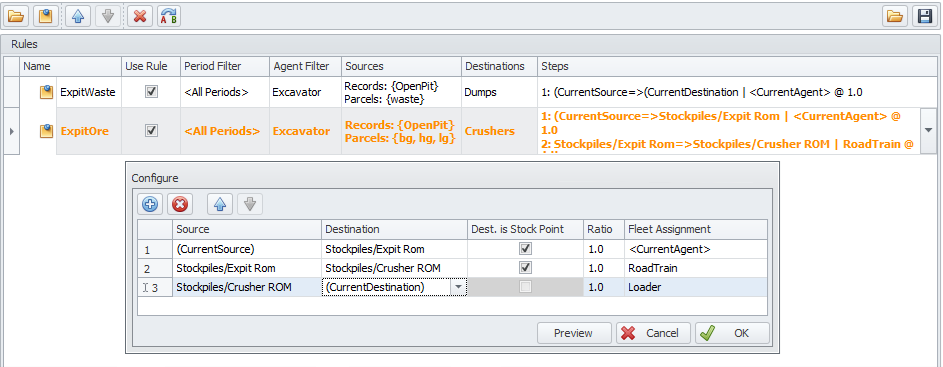

Simple Ore Example

Expit ore goes to the crusher with excess ore going to stockpiles. 20% of all ore going to the crusher, passes through the Crusher ROM stockpile. This 20% could be consider as ‘operational rehandle’. This setup treats Crusher ROM such that all material that flows in, flows out.

Expit Ore Setup:

Row 1

-

Source, Destination & Fleet are all set to current meaning they will use OpenPit, Crusher & Excavator Fleet.

-

Ratio has been set to 0.8. This means 80% of the material from the pit will go directly to the crusher.

Row 2

-

Source & Fleet are all set to current meaning they will use OpenPit & Excavator Fleet.

-

Destination has been set to Crusher ROM and Ratio set to 0.2. This means that 20% of the material from the pit will go to Crusher ROM.

Row 3

-

Destination is set to current meaning it will use Crusher.

-

Source has been set to Crusher ROM, Ratio set to 0.2 and Fleet set to Loader. This means that 20% of the original material will go from the Crusher ROM to the Crusher and be completed by the Loader Fleet.

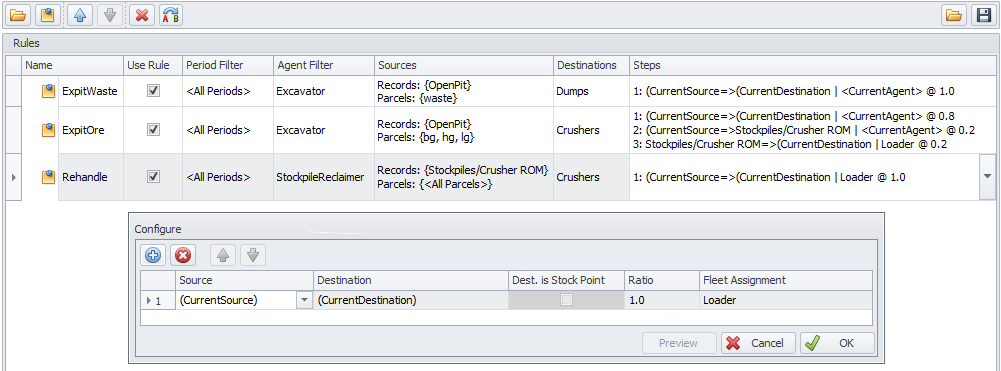

Rehandle Setup:

Row 1

-

Source & Destination are set to current, meaning they will use Crusher ROM & Crusher.

-

Fleet has been set to Loader, meaning the rehandle movement will be assigned to the Loader Fleet.

Steps Logic (Top)

Stock Point Example

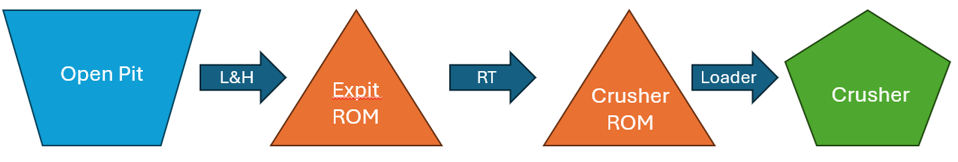

In some cases material is moved from the pit to crusher using multiple steps & fleets with stockpiles in between each step.

The example below is using traditional load and haul to move from the pit to the Expit ROM. Road Trains are then used to transfer material to the Crusher ROM. Loaders then feed the Crusher. The diagram below is very linear and material can only go one step at a time. While this setup will work, it does limit material flow to one step per period, which may not be desired.

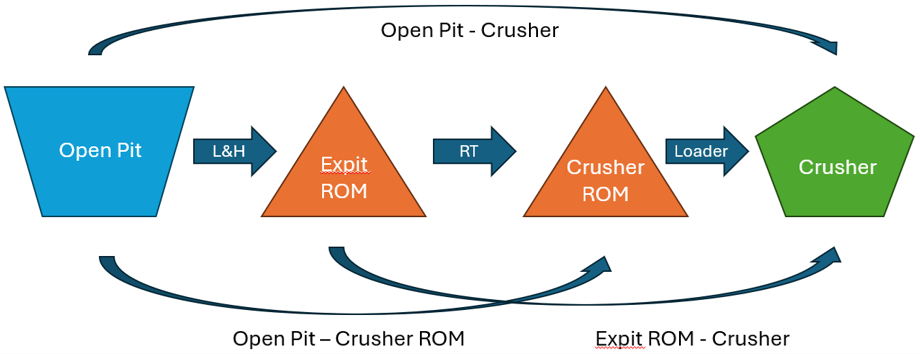

In this example, material should flow from the Open Pit through both ROMs to the Crusher. However, material can be built and reclaimed from the ROMs each period, so these need to be treated both a source and destination. Therefore, the diagram should look more like this.

Note: Movements going across multiple steps are still required to go through the intermediate stock points.

Destination Rules need to be setup to include moving between each source point and appropriate destinations.

Step Logic setup for ore can be simplified to a single step using Dest is Stock Point.

Row 1

-

Source & Fleet are set to current meaning they will use Open Pit & Excavator Fleet.

-

Destination has been set to Expit ROM meaning the material can flow through this stockpile.

-

Dest is Stock point has been ticked means that Expit ROM can be used as a source and destination. This also means that the amount of material being added to the destination does not need to equal what is being removed.

Row 2

-

Source, Destination & Fleet are defined as shown below.

-

Dest is Stock point has been ticked means that Crusher ROM can be used as a source and destination.

Row 3

-

Destination is set to current, meaning it will use the Crusher.

Click Preview to view a full list of all automatically created logic.

Note: Any step logic using Dest. Is Stock Point will be highlighted in orange to indicate the option is being used and potentially creating extra logic.

Tips

-

Between the pit and the waste dump, there is one (100%) pathway, trafficked by the production fleet.

-

Between the stockpile and the crusher there is one (100%) pathway, trafficked by the rehandle fleet.

-

Between the pit and the crusher there may be:

-

One (60%) direct tip pathway, trafficked by the production fleet.

-

One (40%) stockpile pathway, trafficked by the production fleet.

-

One (40%) rehandle pathway, trafficked by the rehandle fleet.

-

-

If you type a field name (i.e. myRatio) instead of a number (i.e. 40%) then this adds a row to the Calendar to change the ratios by period.

-

Ratios MUST be set to 1.0 when using Dest is Stock Point.

-

Rules can be copied by holding down the <CTRL> key and dragging on the clipboard icon.

-

Rules can be archived and shared via the save icon and import icon in the top right of the form.

These rules can be used to split movement across multiple pathways and multiple fleets.

Steps Logic (Top)